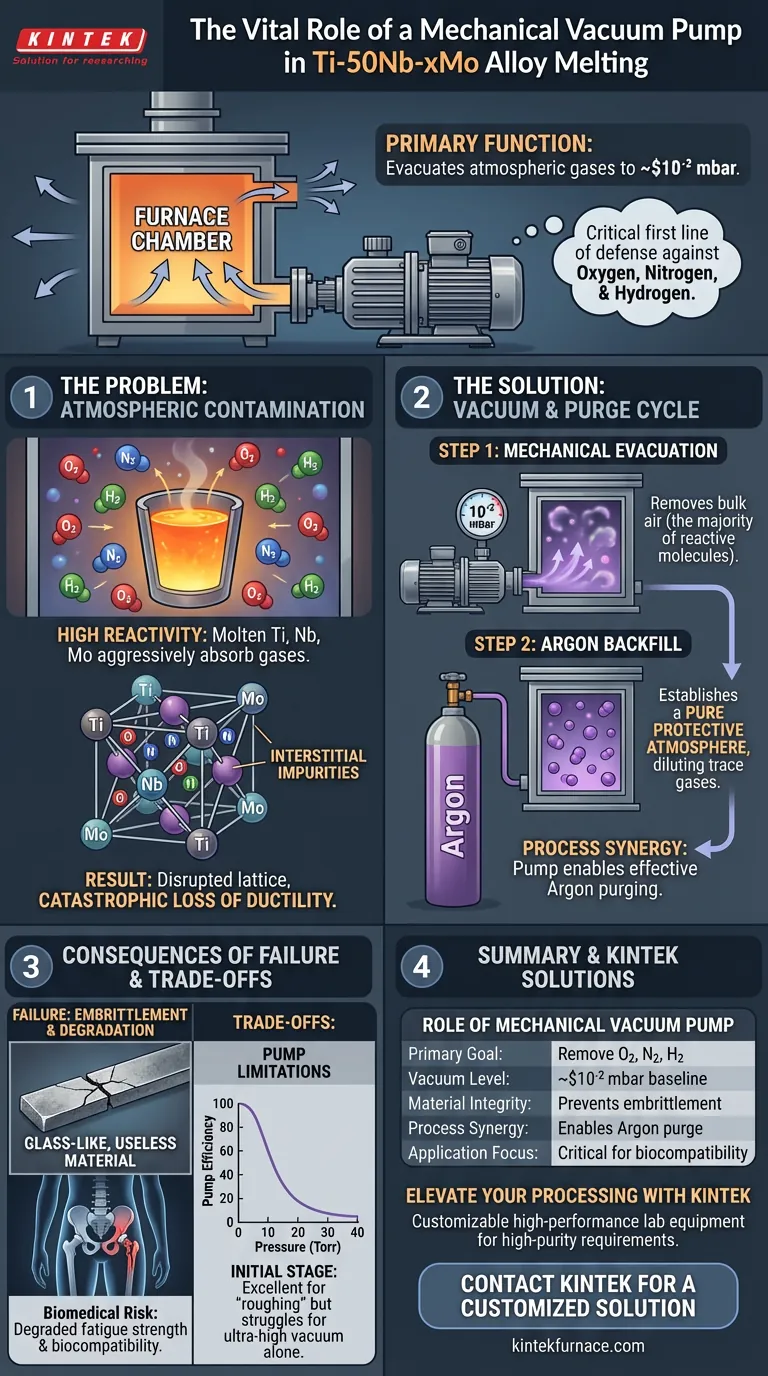

The primary function of a mechanical vacuum pump is to evacuate atmospheric gases from the furnace chamber, creating a baseline vacuum of approximately $10^{-2}$ mbar. This step is a prerequisite to melting Ti-50Nb-xMo alloys because it removes the air that would otherwise react chemically with the metal, ensuring the material retains the mechanical properties required for high-stakes applications.

High-temperature titanium alloys act as "getters," aggressively absorbing gases from their environment. The mechanical pump serves as the critical first line of defense, stripping away oxygen, nitrogen, and hydrogen to prevent the alloy from becoming brittle and structurally compromised.

The Chemistry of Contamination

The Reactivity of Titanium Alloys

Titanium (Ti), Niobium (Nb), and Molybdenum (Mo) are highly reactive metals, particularly when in a molten state.

At elevated temperatures, these elements possess a strong chemical affinity for atmospheric gases. Without a vacuum, the melting pool would instantly begin to absorb elements from the air.

The Threat of Interstitial Impurities

The specific gases removed by the pump—oxygen, nitrogen, and hydrogen—are detrimental to the alloy's crystalline structure.

When these atoms are absorbed, they act as interstitial impurities, occupying the spaces between the metal atoms. This intrusion prevents the metal lattice from shifting smoothly under stress, leading to a catastrophic loss of ductility.

The Mechanism of Protection

Achieving Low Pressure

The mechanical pump forcibly extracts air from the chamber, reducing the pressure from atmospheric levels down to roughly $10^{-2}$ mbar.

This drastic reduction in pressure physically removes the vast majority of gas molecules that could interact with the melt.

The Argon Purge Cycle

The vacuum pump is rarely used in isolation; it enables a technique known as vacuum purging.

Once the pump evacuates the air, the chamber is backfilled with Argon, an inert gas. By combining mechanical evacuation with an argon purge, the operator establishes a pure protective atmosphere that shields the alloy during the melting process.

Consequences of Failure

Severe Embrittlement

If the mechanical pump fails to remove these impurities, the resulting alloy will suffer from embrittlement.

Instead of being tough and flexible, the metal becomes glass-like and prone to cracking. For an alloy like Ti-50Nb-xMo, which relies on specific mechanical ratios, this renders the material useless.

Degradation of Biomedical Performance

Ti-50Nb-xMo is frequently engineered for biomedical applications, such as implants.

If the alloy absorbs impurities due to a poor vacuum, its fatigue strength and biocompatibility degrade. An implant made from embrittled material poses a severe risk of fracturing inside the patient's body.

Understanding the Trade-offs

Mechanical Pump Limitations

While essential, the mechanical pump is generally the initial stage of the vacuum process.

As noted in vacuum engineering, the efficiency of a mechanical pump begins to decline significantly at pressures below 20 torr. It is excellent for "roughing" the chamber (removing the bulk of the air), but it struggles to achieve ultra-high vacuum levels on its own.

The Necessity of Multi-Stage Processes

Because of the mechanical pump's efficiency curve, relying on it alone without an Argon backfill or a secondary high-vacuum pump (like a diffusion pump) may be insufficient for extreme purity requirements.

The mechanical pump clears the "bulk" atmosphere, but the Argon purge is the necessary second step to dilute and displace any remaining trace gases that the pump cannot reach efficiently.

Making the Right Choice for Your Project

The use of a mechanical vacuum pump is not optional when working with reactive titanium alloys. To ensure success, align your process with your end goals:

- If your primary focus is Biomedical Safety: Prioritize the removal of Oxygen and Nitrogen above all else; even trace amounts will compromise the safety of an implant.

- If your primary focus is Alloy Ductility: Ensure your process includes multiple cycles of evacuation (via the pump) followed by Argon purging to minimize interstitial hardening.

In summary, the mechanical pump acts as the gatekeeper of quality, clearing the stage of reactive impurities so the alloy can be melted without sacrificing its structural integrity.

Summary Table:

| Feature | Role of Mechanical Vacuum Pump in Ti-Alloy Melting |

|---|---|

| Primary Goal | Removes atmospheric gases (O2, N2, H2) to prevent chemical reactions |

| Vacuum Level | Achieves a baseline "rough" vacuum of approximately $10^{-2}$ mbar |

| Material Integrity | Prevents interstitial impurities that cause metal embrittlement |

| Process Synergy | Enables effective Argon purging cycles for an inert atmosphere |

| Application Focus | Critical for maintaining biocompatibility in medical implants |

Elevate Your Materials Processing with KINTEK

Don't let atmospheric contamination compromise the integrity of your reactive alloys. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of high-performance lab equipment, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are melting Ti-50Nb-xMo for biomedical implants or industrial applications, our furnaces are fully customizable to meet your unique high-temperature and vacuum requirements.

Ready to ensure the highest purity for your next project? Contact KINTEK today for a customized solution!

Visual Guide

References

- José Roberto Severino Martins, Carlos Roberto Grandini. Investigation of the Chemical Composition, Microstructure, Density, Microhardness, and Elastic Modulus of the New β Ti-50Nb-xMo Alloys for Biomedical Applications. DOI: 10.3390/ma17010250

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What functions do alumina crucibles and quartz tube encapsulation serve? Essential Shields for Na2In2As3 Synthesis

- What are the advantages of using a Boron Nitride crucible? Maximize Purity and Efficiency in Laser Pyrolysis

- Why are high-temperature ceramic crucibles used for chalcopyrite? Ensure Purity in Ore Thermal Treatment

- What are the advantages of using a single-mode microwave generator? Precision Heating for Metal Recovery

- Why are high-purity alumina or ceramic boats required in a tube furnace? Protect Your Lab Equipment & Ensure Purity

- Why are a press and pelletizing molds necessary when preparing pellets for magnesium smelting? Ensure Smelting Efficiency and Control

- What processes can a circulating water vacuum pump provide negative pressure conditions for? Essential Lab Techniques Explained

- Why use a PLC and touch screen for magnesium vacuum distillation? For Superior Control and Safety