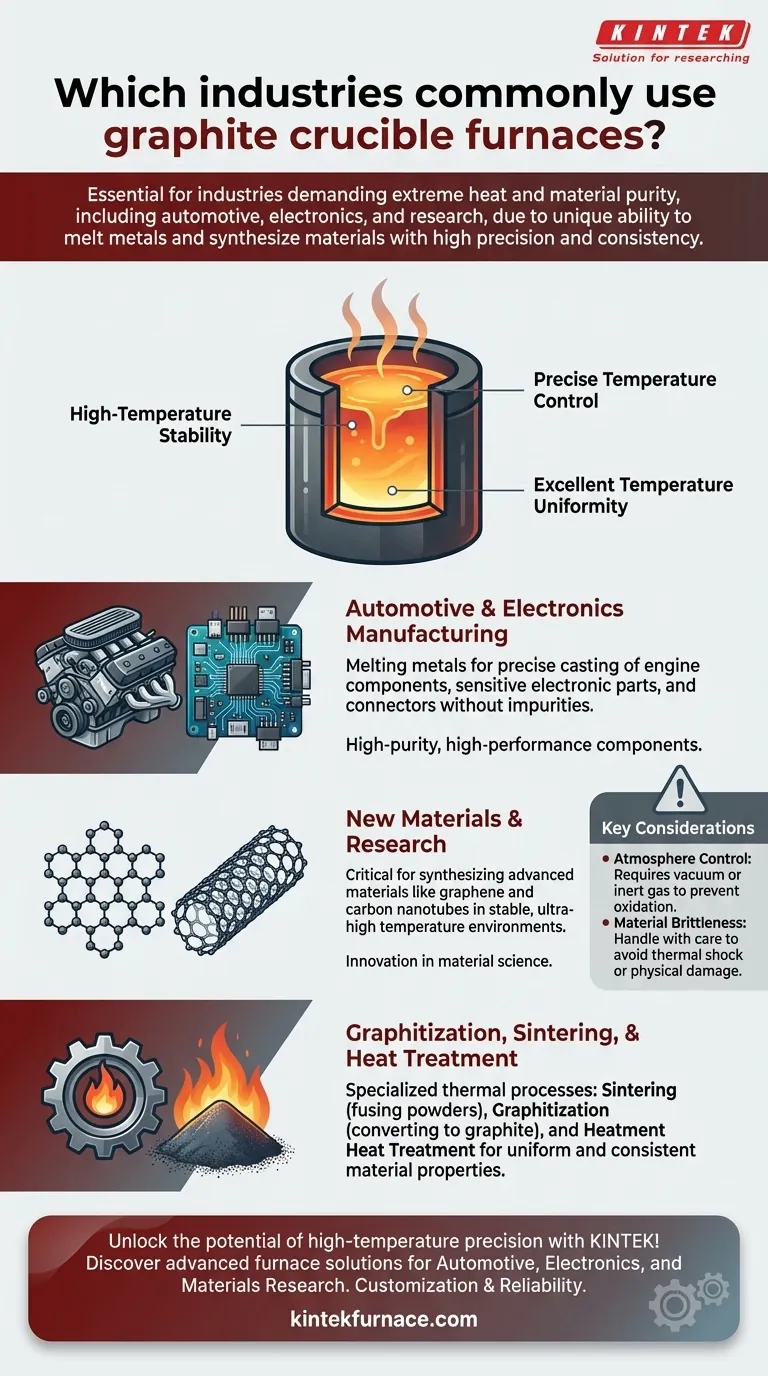

In short, graphite crucible furnaces are essential tools in industries that demand extreme heat and material purity, most notably in automotive parts manufacturing, electronics, and the research and development of new materials. Their unique ability to melt metals and synthesize materials with high precision and consistency makes them indispensable for creating high-performance components.

The decision to use a graphite crucible furnace is driven by a need for exceptional thermal performance. Its value lies not just in reaching high temperatures, but in maintaining them with precise control and uniformity, which is critical for producing materials with specific, repeatable properties.

The Core Function of Graphite Crucible Furnaces

A graphite crucible furnace is not just a simple heater; it's a high-precision instrument designed for specific thermal processes. Its capabilities are defined by the unique properties of graphite.

High-Temperature Stability

Graphite has an exceptionally high melting point and maintains its structural integrity at temperatures where most metals would vaporize. This makes it the ideal material for containing molten metals and other substances in extreme heat environments.

Precise Temperature Control

Modern graphite furnaces offer fast heating speeds and sophisticated control systems. This allows operators to manage the thermal process with a high degree of accuracy, which is crucial for creating specific metal alloys or advanced material structures.

Excellent Temperature Uniformity

These furnaces are engineered to distribute heat evenly throughout the crucible. This uniformity prevents hot spots, ensuring that the entire batch of material melts or undergoes heat treatment consistently, leading to reliable and predictable end products.

Key Industrial Applications

The unique capabilities of graphite furnaces make them a preferred choice in several advanced manufacturing and research sectors.

Automotive and Electronics Manufacturing

Both industries rely on high-purity, high-performance metal components. Graphite crucible furnaces are used to melt metals for casting precise parts, from engine components to sensitive electronic connectors, without introducing impurities.

New Materials and Research

This is a critical area where graphite furnaces excel. They are used in the production of advanced materials like graphene and carbon nanotubes, which require the stable, ultra-high temperature environment that only a graphite furnace can provide.

Graphitization, Sintering, and Heat Treatment

Graphite furnaces are also employed for specialized heat treatment processes. Sintering (fusing powdered material together with heat) and graphitization (converting carbonaceous materials into graphite) are essential processes in material science that depend on the controlled, high-heat environment of these furnaces.

Understanding the Trade-offs and Considerations

While powerful, graphite crucible furnaces are not a universal solution. Understanding their operational requirements is key to using them effectively.

Atmosphere Control is Crucial

Graphite will oxidize (burn away) at high temperatures in the presence of oxygen. Therefore, these furnaces must be operated with a vacuum or an inert gas atmosphere (like argon) to protect the crucible and heating elements, adding complexity and cost to the operation.

Material Brittleness

Graphite is a ceramic material and can be brittle. Crucibles must be handled with care to avoid thermal shock (cracking from rapid temperature changes) or physical damage, which could lead to catastrophic failure during a melt.

Making the Right Choice for Your Process

Your specific goal determines whether a graphite crucible furnace is the appropriate tool.

- If your primary focus is casting high-purity metal alloys: The key benefit is the combination of precise temperature control and the non-reactive nature of the graphite crucible.

- If your primary focus is advanced materials research: The furnace's ability to achieve extreme, uniform temperatures is the most critical factor for synthesizing materials like graphene or for graphitization processes.

- If your primary focus is sintering or heat treating components: The fast heating rates and excellent temperature uniformity ensure consistent material properties across the entire batch.

Ultimately, a graphite crucible furnace is the definitive choice for any process where thermal precision and material purity cannot be compromised.

Summary Table:

| Industry/Application | Key Use Cases |

|---|---|

| Automotive Manufacturing | Melting metals for engine parts, casting high-purity components |

| Electronics Manufacturing | Producing connectors, ensuring material purity in electronic parts |

| New Materials Research | Synthesizing graphene, carbon nanotubes, advanced material development |

| Graphitization/Sintering | Converting materials to graphite, fusing powders for consistent properties |

| Heat Treatment | Applying uniform heat for reliable material performance and repeatability |

Unlock the potential of high-temperature precision with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced graphite crucible furnaces and other solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental needs in automotive, electronics, or materials research are met with reliability and efficiency. Contact us today to discuss how our furnaces can enhance your processes and deliver superior results!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control

- What safety precautions should be followed when operating a multi zone tube furnace? Ensure Safe and Efficient Lab Operations

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing