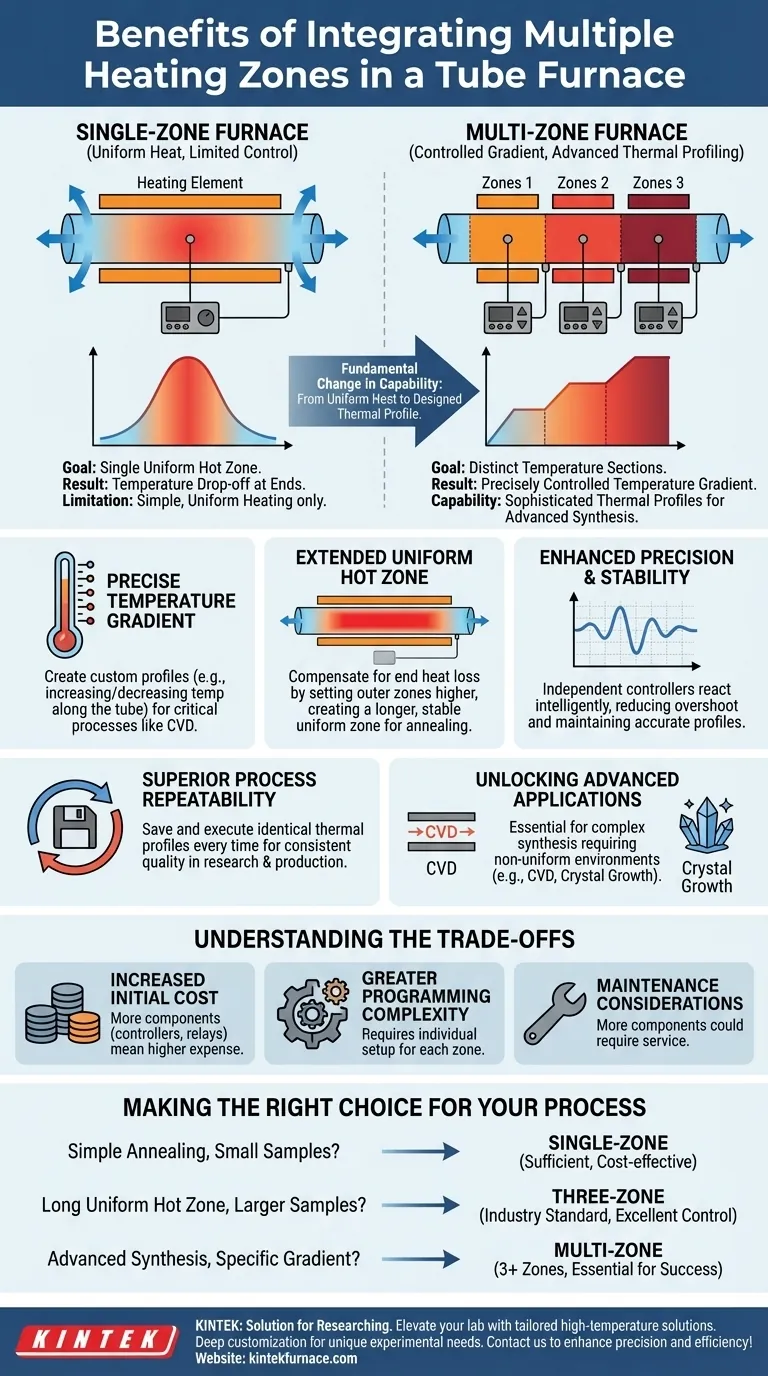

The primary benefit of integrating multiple heating zones in a tube furnace is the ability to create a precisely controlled temperature gradient along the length of the processing tube. Instead of a single uniform temperature, you can set specific, different temperatures for each section, enabling advanced thermal processing techniques that are impossible with a single-zone furnace.

Moving from a single-zone to a multi-zone furnace fundamentally changes its capability. You graduate from simple, uniform heating to the sophisticated control required to design and execute complex thermal profiles for advanced material synthesis and analysis.

From Uniform Heat to a Designed Thermal Profile

The core function of a tube furnace is to provide a controlled thermal environment. The number of heating zones directly dictates the level of control you can achieve within that environment.

The Limitation of a Single Zone

A single-zone furnace has one heating element and one controller. Its goal is to create a single, uniform hot zone in the center of the tube.

However, heat naturally escapes from the ends of the tube. This results in a temperature drop-off, meaning the "uniform" hot zone is often shorter than the heated length of the furnace.

Achieving a Controlled Temperature Gradient

A multi-zone furnace divides the heated length into distinct sections, each with its own independent heating element and thermocouple. This allows you to program a unique temperature for each zone.

For example, you can create a profile where the temperature gradually increases or decreases along the tube, which is critical for processes like chemical vapor deposition (CVD) or directional solidification.

Extending the Uniform Hot Zone

A key application of a multi-zone system is to create a longer and more precise uniform temperature zone. This is a common requirement in materials annealing and testing.

By setting the outer zones to a slightly higher temperature than the center zone, you can actively compensate for the heat loss at the ends. This effectively flattens the thermal profile and extends the length of the stable, uniform hot zone.

Practical Advantages in Research and Production

The ability to create custom thermal profiles translates into significant practical benefits for both scientific research and industrial production.

Enhanced Precision and Stability

With multiple independent controllers, the system can react more intelligently to maintain the desired temperatures. This results in greater stability, less temperature overshoot, and a more accurate adherence to the programmed thermal profile across the entire sample.

Superior Process Repeatability

Once a specific multi-zone temperature profile is optimized for a process, it can be saved and executed identically every time. This high degree of repeatability is essential for validating research results and ensuring consistent quality in a manufacturing setting.

Unlocking Advanced Applications

Many modern material synthesis techniques rely on a non-uniform temperature environment. A multi-zone furnace is a prerequisite for processes that require controlled heating and cooling stages to occur simultaneously across a sample.

Understanding the Trade-offs

While powerful, a multi-zone furnace is not always the necessary choice. Objectivity requires acknowledging the trade-offs involved.

Increased Initial Cost

The most significant factor is cost. Each additional zone requires its own controller, power relay, and thermocouple, making multi-zone furnaces considerably more expensive than their single-zone counterparts.

Greater Programming Complexity

Setting up a multi-zone furnace requires more effort. You must program the setpoint for each zone individually to create the desired profile, which introduces a layer of complexity compared to setting a single temperature.

Maintenance Considerations

While modern furnace technology is highly reliable, more components inherently mean more potential points of failure. A system with three controllers has more electronic parts that could eventually require service compared to a system with one.

Making the Right Choice for Your Process

The decision between a single-zone and multi-zone furnace should be driven entirely by the requirements of your thermal process.

- If your primary focus is simple annealing or heating of small, centered samples: A single-zone furnace is often sufficient, more cost-effective, and simpler to operate.

- If your primary focus is creating a long, highly uniform hot zone for larger samples or batch processing: A three-zone furnace is the industry standard and provides excellent control.

- If your primary focus is advanced material synthesis (e.g., CVD, crystal growth) requiring a specific temperature gradient: A multi-zone furnace with three or more zones is essential for process success.

Ultimately, choosing the right furnace is about matching the tool's level of control to the complexity of your application.

Summary Table:

| Benefit | Description |

|---|---|

| Precise Temperature Gradient | Allows setting different temperatures in each zone for controlled heating and cooling profiles. |

| Extended Uniform Hot Zone | Compensates for heat loss to create a longer, stable uniform temperature area. |

| Enhanced Process Repeatability | Saves and replicates exact thermal profiles for consistent results in research and production. |

| Support for Advanced Applications | Enables complex processes like chemical vapor deposition (CVD) and crystal growth. |

| Improved Stability and Precision | Independent controllers reduce temperature overshoot and maintain accurate profiles. |

Ready to elevate your laboratory's capabilities with tailored high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, whether for research or production. Contact us today to discuss how our multi-zone tube furnaces can enhance your precision and efficiency!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What safety precautions should be followed when operating a multi zone tube furnace? Ensure Safe and Efficient Lab Operations

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials

- What steps are involved in the installation of a multi zone tube furnace? Ensure Precision and Safety for Your Lab

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing