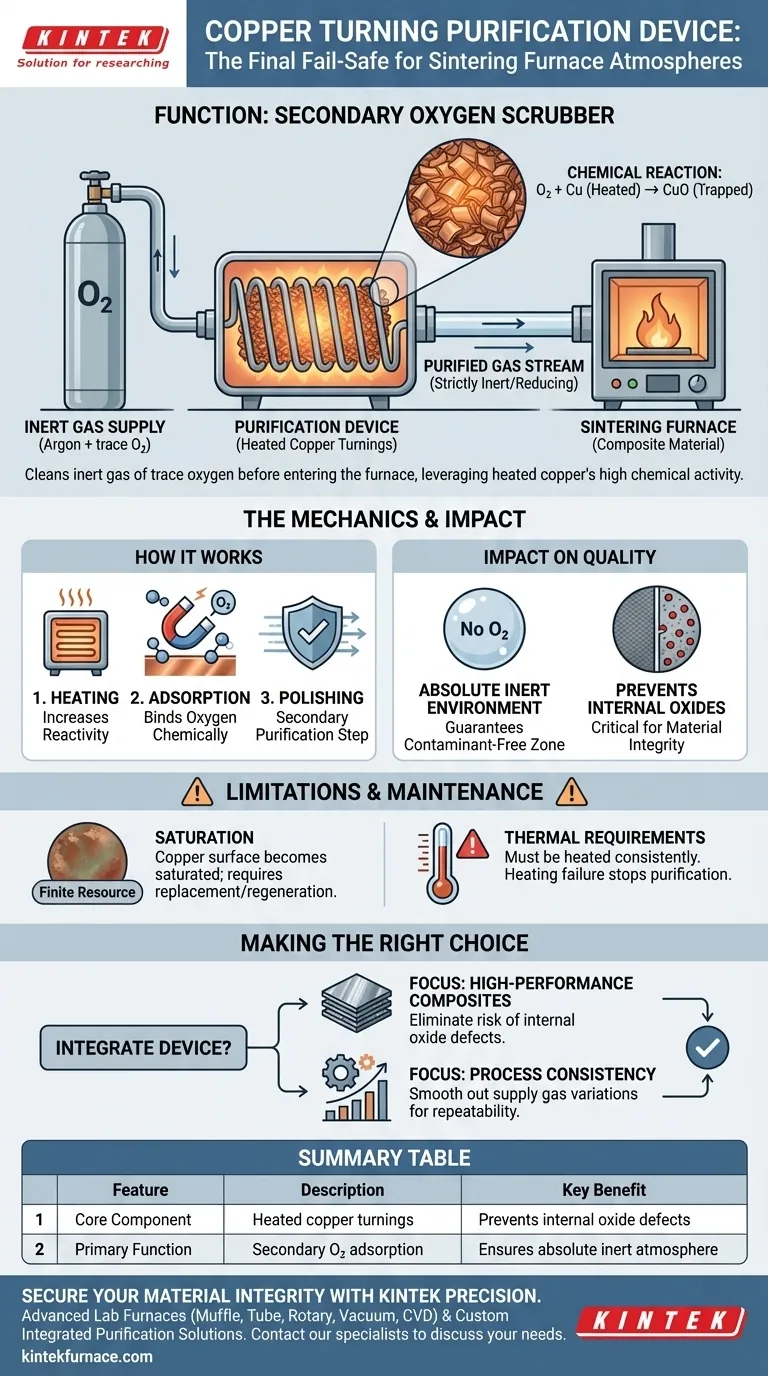

A copper turning purification device functions as a specialized secondary oxygen scrubber within the argon gas supply of a sintering furnace. By routing the inert gas over heated copper turnings, the system leverages the high chemical activity of the hot metal to react with and adsorb trace amounts of residual oxygen. This process effectively strips impurities from the gas stream before it enters the tube furnace, ensuring the atmosphere remains strictly inert or reducing.

While standard inert gases are generally pure, even microscopic traces of oxygen can compromise sensitive composite materials during high-temperature processing. This device acts as a final fail-safe, chemically trapping residual oxygen to prevent internal oxidation defects in the final product.

The Mechanics of Purification

Leveraging Chemical Activity

The core principle of this device is the chemical activity of copper when exposed to heat.

While copper is relatively stable at room temperature, heating the turnings increases their reactivity significantly.

The Adsorption Process

As the argon gas flows over these heated turnings, any oxygen molecules present are attracted to the copper surface.

The copper "adsorbs" the oxygen, effectively removing it from the gas stream through a chemical reaction that binds the oxygen to the copper.

Secondary Purification

This device is designed as a secondary purification step, meaning it polishes the gas after it leaves the main supply but before it enters the reaction chamber.

It addresses the limitations of standard gas supplies, which may still contain trace impurities capable of affecting sensitive sintering processes.

Impact on Sintering Quality

Ensuring an Absolute Inert Environment

The primary goal of the sintering furnace is to create a controlled environment free from reactive elements.

By removing the final traces of oxygen, the copper purification device guarantees an absolute inert or reducing atmosphere.

Preventing Internal Oxides

The presence of oxygen during sintering can lead to the formation of unwanted oxides inside the material structure.

This device minimizes the formation of these internal oxides, which is critical for maintaining the structural integrity and desired properties of composite materials.

Understanding the Limitations

Saturation and Replacement

Because the device relies on the copper chemically binding with oxygen, the turnings are finite resources.

Eventually, the surface area of the copper will become saturated with oxygen (oxidized), and the turnings will lose their ability to purify the gas, requiring replacement or regeneration.

Thermal Requirements

The effectiveness of the purification relies heavily on the copper being heated.

If the heating element within the purification device fails or fluctuates, the chemical activity of the copper drops, and oxygen may pass through to the furnace unchecked.

Making the Right Choice for Your Process

For material scientists and engineers configuring a sintering furnace, the inclusion of this device depends on material sensitivity.

- If your primary focus is High-Performance Composites: Implement this device to eliminate the risk of internal oxide formation that could weaken structural integrity.

- If your primary focus is Process Consistency: Use this device to smooth out variations in supply gas purity, ensuring a repeatable inert environment every cycle.

Integrating a copper turning purifier transforms a standard inert gas supply into a high-grade atmosphere suitable for the most demanding sintering applications.

Summary Table:

| Feature | Description |

|---|---|

| Core Component | Heated copper turnings |

| Primary Function | Secondary oxygen adsorption/purification |

| Target Gas | Argon or other inert supply gases |

| Key Benefit | Prevents internal oxide defects in composites |

| Requirement | Consistent heating for chemical activity |

| Maintenance | Periodic replacement of saturated copper turnings |

Secure Your Material Integrity with KINTEK Precision

Don't let trace oxygen compromise your high-performance composites. KINTEK’s advanced lab high-temp furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—are backed by expert R&D and can be customized with integrated copper turning purification devices to ensure an absolute inert environment.

Take control of your sintering atmosphere today. Contact our specialists to discuss your custom furnace needs and see how our manufacturing expertise can deliver the repeatable process consistency your research demands.

Visual Guide

References

- Ahmet Köken. INVESTIGATION OF THE INFLUENCE OF B4C REINFORCEMENT RATIO AND SINTERING TEMPERATURE ON MECHANICAL AND MICROSTRUCTURAL PROPERTIES OF Al6061-BASED METAL MATRIX COMPOSITES. DOI: 10.36306/konjes.1610106

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does an alumina crucible play during the gas nitriding process for stainless steel? Ensure Surface Purity

- What is the function of a vacuum system in PLD? Ensure High-Density, Pure Electrolyte Thin Films

- Why is a glovebox environment necessary for KBaBi synthesis? Protect Sensitive Raw Materials Today

- What is the function of a vacuum ampoule during the synthesis of ZnGeP2? Ensure Purity and Chemical Stability

- What is the role of gold (Au), platinum (Pt), or platinum-iridium (Pt-Ir) foil in silicate melt experiments?

- What is the importance of the constant temperature environment provided by a heating stage? Expert Lab Solutions

- Why use R-type and K-type thermocouples for slag measurement? Optimize High-Temp Thermal Profiling and Modeling

- What creates the pumping action in a circulating water vacuum pump? Discover the Liquid Ring Mechanism