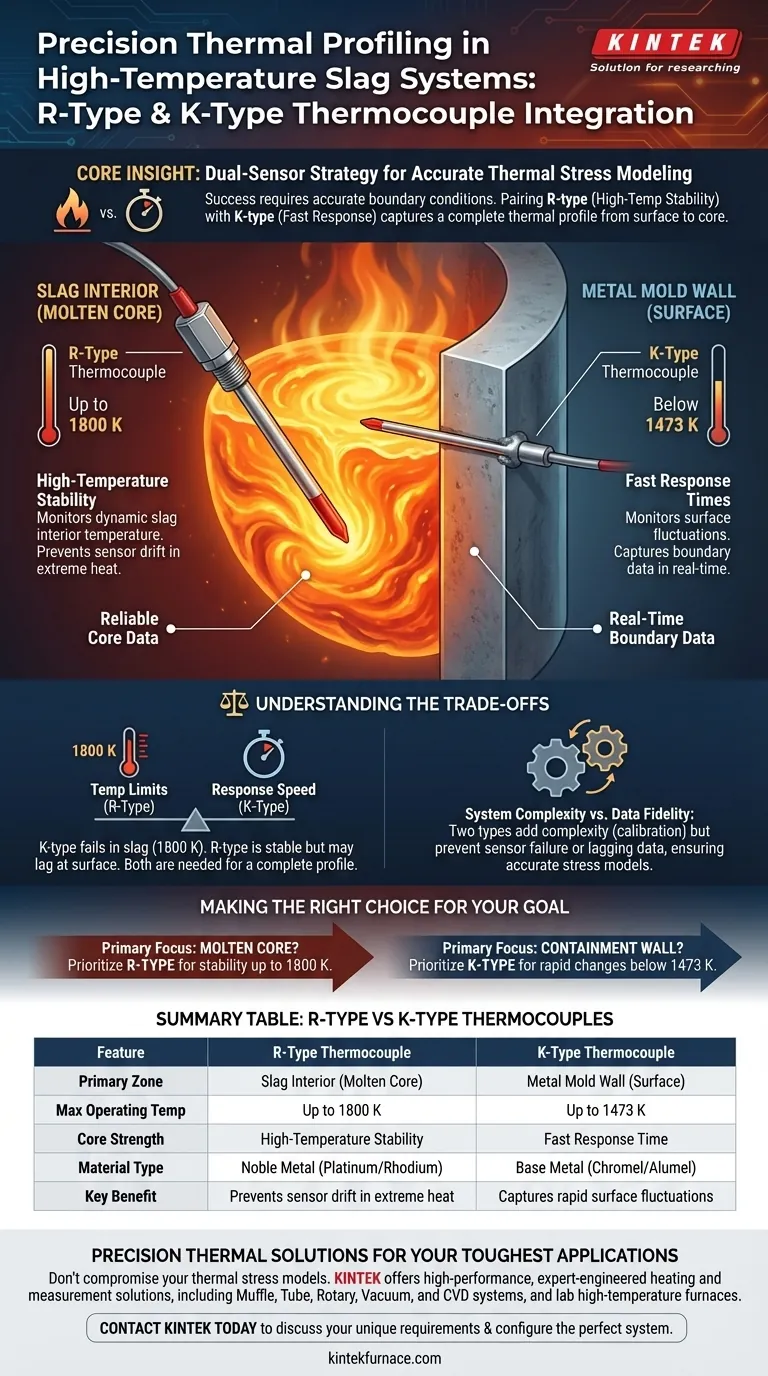

The simultaneous use of R-type and K-type sheathed thermocouples allows for precise measurement across distinct thermal zones within a single high-temperature system. This dual-sensor strategy leverages the superior stability of R-type sensors for the extreme heat of the molten slag interior, while utilizing the rapid response capabilities of K-type sensors for the cooler metal mold walls.

Core Insight: Successful thermal stress modeling requires accurate boundary conditions that a single sensor type cannot provide. By pairing R-type sensors (high-temperature stability) with K-type sensors (fast response), engineers can capture a complete thermal profile ranging from surface interactions to the core melt.

Targeted Application for Distinct Zones

To accurately model thermal stress, you must monitor two very different environments: the dynamic molten core and the solid containing wall.

Monitoring the Slag Interior (R-Type)

The interior of the slag requires a sensor capable of withstanding extreme conditions without drifting. R-type thermocouples are specifically selected for this zone because of their exceptional high-temperature stability.

They are deployed to monitor the dynamic temperature of the slag interior, where temperatures can reach up to 1800 K. At these ranges, base-metal thermocouples would degrade rapidly, but the R-type maintains accuracy to provide reliable core data.

Monitoring the Metal Wall (K-Type)

The requirements change at the mold surface, where temperatures are lower, but thermal fluctuations can happen quickly. K-type sheathed thermocouples are ideal here due to their fast response times and linear characteristics.

These sensors are typically welded directly to the mold surface to monitor metal wall temperatures, which generally remain below 1473 K. Their ability to react quickly to surface changes ensures that the boundary data for the metal wall is captured in real-time.

Understanding the Trade-offs

Designing a measurement system is rarely about finding a "perfect" sensor, but rather managing the limitations of each type.

Temperature Limits vs. Response Speed

You cannot simply use K-type sensors for the entire system because they cannot survive the 1800 K environment of the slag interior. Conversely, while R-type sensors could theoretically measure the lower temperatures, they are often more expensive and may not match the fast transient response required for surface monitoring.

System Complexity vs. Data Fidelity

Integrating two different thermocouple types adds complexity to the data acquisition setup, as each requires specific calibration and compensation. However, this complexity is necessary. Relying on a single type would result in either sensor failure in the slag or lagging data on the mold wall, compromising the accuracy of your thermal stress models.

Making the Right Choice for Your Goal

When designing a thermal monitoring system for high-temperature metallurgy, select your sensors based on the specific location and thermal load of the measurement point.

- If your primary focus is the molten core: Prioritize R-type thermocouples to ensure stability and survival in temperatures up to 1800 K.

- If your primary focus is the containment vessel or wall: Prioritize K-type thermocouples to capture rapid thermal changes and surface fluctuations below 1473 K.

By matching the sensor's strengths to the specific zone's demands, you ensure the integrity of your thermal data and the validity of your stress models.

Summary Table:

| Feature | R-Type Thermocouple | K-Type Thermocouple |

|---|---|---|

| Primary Zone | Slag Interior (Molten Core) | Metal Mold Wall (Surface) |

| Max Operating Temp | Up to 1800 K | Up to 1473 K |

| Core Strength | High-Temperature Stability | Fast Response Time |

| Material Type | Noble Metal (Platinum/Rhodium) | Base Metal (Chromel/Alumel) |

| Key Benefit | Prevents sensor drift in extreme heat | Captures rapid surface fluctuations |

Precision Thermal Solutions for Your Toughest Applications

Don't compromise your thermal stress models with inadequate data. KINTEK provides high-performance, expert-engineered heating and measurement solutions tailored to your lab's specific needs. Backed by industry-leading R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temperature furnaces designed for extreme precision.

Whether you are monitoring molten slag or complex metal interactions, our technical team is ready to help you configure the perfect system. Contact KINTEK today to discuss your unique requirements and see how our advanced furnace technology can enhance your research and production efficiency.

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is a high-precision electronic balance critical in the formulation of geopolymer binders? Precision for Success

- How does a laboratory vacuum pump system contribute to the preparation process of TixNbMoTaW refractory alloys?

- Why is a vacuum pump necessary for bio-adsorbent performance assessments? Ensuring Industrial Viability in VSA

- What are the main types of laboratory furnaces? Find Your Perfect High-Temperature Solution

- Why is a precision laboratory hydraulic press required for sulfide-based batteries? Achieve Critical Ion Conductivity

- What are the technical advantages of using a high-purity alumina crucible for the synthesis of MnBi2Te4?

- What is the function of a rotary evaporator in the recovery of formic acid lignin? Preserve Quality & Boost Efficiency

- How does the design of a graphite box optimize the sulfurization of Sb thin films? Key Insights for Film Uniformity