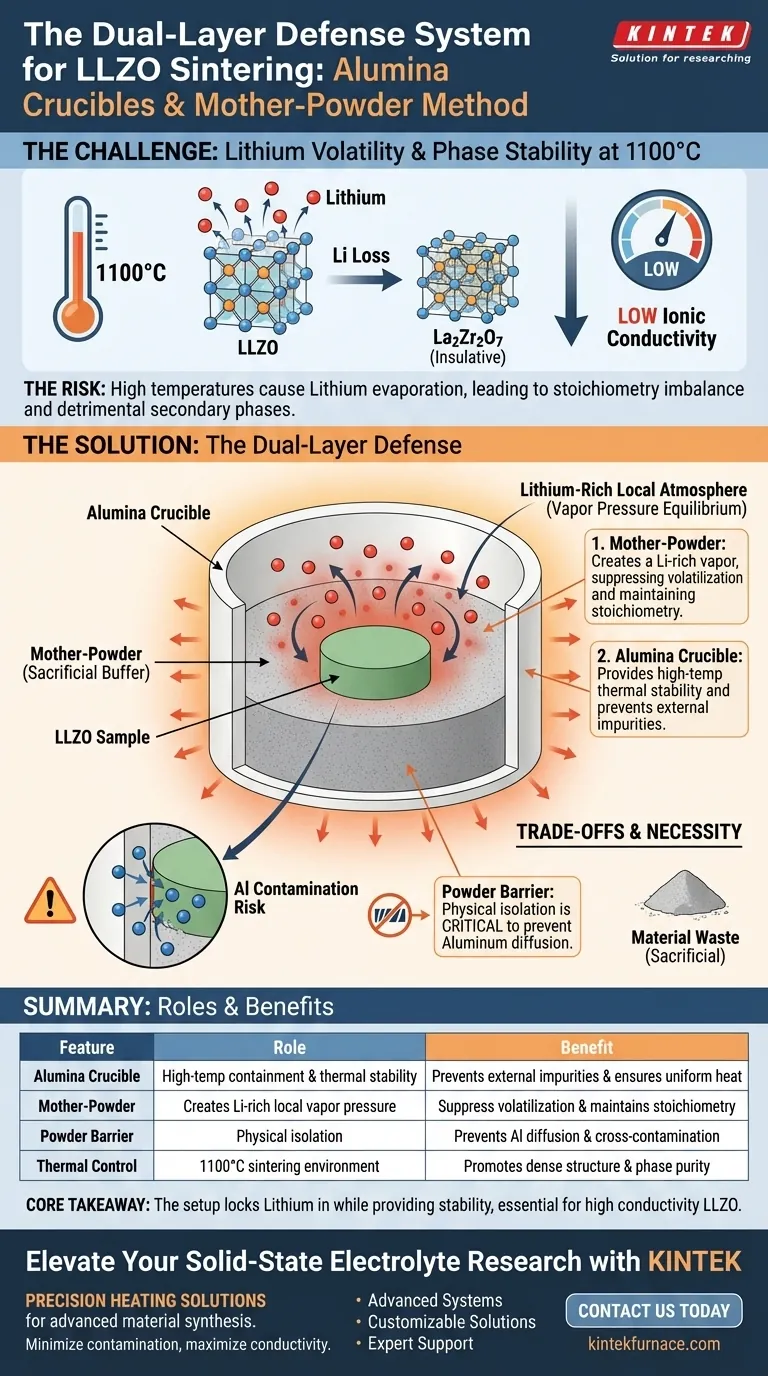

The combination of alumina crucibles and the mother-powder covering method provides a dual-layer defense system essential for maintaining the chemical integrity of LLZO during sintering. While the alumina crucible serves as a thermally stable container, the mother powder acts as a sacrificial buffer that creates a lithium-rich local atmosphere. This setup prevents the catastrophic loss of lithium at high temperatures and shields the sample from physical contamination.

Core Takeaway The sintering process subjects LLZO to temperatures where lithium becomes highly volatile, risking stoichiometry imbalances and the formation of insulative secondary phases. The mother-powder method counters this by establishing a local vapor pressure equilibrium, effectively locking the lithium inside the sample structure while the alumina crucible provides the necessary thermal stability.

The Challenge: Lithium Volatility and Phase Stability

The Risk of High Temperatures

Sintering LLZO often requires temperatures around 1100°C. At this intense heat, lithium becomes volatile and tends to evaporate from the material structure.

Consequences of Lithium Loss

If lithium escapes, the precise stoichiometry of the LLZO is disrupted. This imbalance triggers the formation of undesirable secondary phases, most notably La2Zr2O7 (Lanthanum Zirconate).

Impact on Performance

These secondary phases are detrimental to the material's function. They typically result in significantly lower ionic conductivity, rendering the solid-state electrolyte ineffective.

The Solution: The Mother-Powder Mechanism

Creating a Local Equilibrium

The mother-powder method involves burying or wrapping the LLZO sample in a powder of the exact same composition. As the system heats up, the lithium in this sacrificial powder vaporizes first.

Suppressing Volatilization

This vaporization creates a local environment saturated with lithium vapor. Because the vapor pressure outside the sample matches the pressure inside, further evaporation from the actual sample is physically suppressed.

Physical Isolation

Beyond vapor pressure control, the powder serves as a physical spacer. It prevents the LLZO pellet from coming into direct contact with the crucible walls, which is critical for preventing cross-contamination.

The Role of the Alumina Crucible

High-Temperature Stability

Alumina (aluminum oxide) is selected primarily for its excellent chemical stability and heat resistance. It maintains structural integrity at sintering temperatures where other materials might soften or degrade.

Impurity Containment

A high-quality alumina crucible acts as a clean vessel. It prevents external impurities from the furnace environment from leaching into the electrolyte sample.

Heat Transfer Facilitation

The crucible provides a consistent thermal mass. This ensures that heat is transferred evenly to the powder and the sample, promoting uniform sintering.

Understanding the Trade-offs

The Aluminum Reaction Risk

While alumina is stable, it is not perfectly inert regarding LLZO. If the LLZO pellet touches the alumina crucible directly at high heat, aluminum can diffuse into the sample, causing aluminum contamination.

The Necessity of the Barrier

This is why the mother powder is non-negotiable. It acts as a necessary barrier; without it, the reaction between the crucible and the sample would degrade the electrolyte, regardless of how stable the crucible is on its own.

Material Waste

The primary downside of this method is material efficiency. The mother powder is essentially sacrificial material that cannot be reused for pellets, increasing the overall cost of the synthesis process.

Making the Right Choice for Your Goal

To maximize the conductivity and purity of your solid-state electrolyte, apply these principles:

- If your primary focus is preventing secondary phases: Ensure the mother powder completely surrounds the sample to maintain a consistent lithium vapor pressure equilibrium.

- If your primary focus is avoiding aluminum contamination: Verify that the powder layer is thick enough to physically isolate the pellet from the crucible walls entirely.

Success in LLZO sintering relies not just on heat, but on creating a micro-climate that forces lithium to stay exactly where it belongs.

Summary Table:

| Feature | Role in LLZO Sintering | Benefit to Final Material |

|---|---|---|

| Alumina Crucible | High-temp containment & thermal stability | Prevents external impurities & ensures uniform heat |

| Mother-Powder | Creates lithium-rich local vapor pressure | Suppresses lithium volatilization & maintains stoichiometry |

| Powder Barrier | Physical isolation between pellet and wall | Prevents aluminum diffusion and cross-contamination |

| Thermal Control | 1100°C sintering environment | Promotes dense electrolyte structure and phase purity |

Elevate Your Solid-State Electrolyte Research with KINTEK

Precision in LLZO sintering requires more than just high temperatures—it demands the right environment. KINTEK provides the high-performance heating solutions necessary to master complex material synthesis.

Why partner with KINTEK?

- Advanced Systems: Our Muffle, Tube, Vacuum, and CVD systems offer the precise thermal control needed for delicate sintering processes.

- Customizable Solutions: Backed by expert R&D and manufacturing, we tailor our lab high-temp furnaces to meet your unique material requirements.

- Expert Support: We help target customers like you minimize contamination and maximize ionic conductivity through superior equipment engineering.

Ready to achieve consistent, high-purity results? Contact our technical experts today to find the perfect furnace for your laboratory.

Visual Guide

References

- Seung Hoon Chun, Sangbaek Park. Synergistic Engineering of Template‐Guided Densification and Dopant‐Induced Pore Filling for Pressureless Sintering of Li<sub>7</sub>La<sub>3</sub>Zr<sub>2</sub>O<sub>12</sub> Solid Electrolyte at 1000 °C. DOI: 10.1002/sstr.202500297

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What role do laboratory furnaces play in quality control? Ensure Material Integrity and Product Reliability

- What is the tank capacity of the water circulating vacuum pump? Find the Perfect Fit for Your Lab

- What is the core function of a planetary ball mill in Bi2Te3 alloying? Drive Solid-State Reaction & Nanoscale Refinement

- What are the advantages of using a two-color pyrometer? Precision Sensing for Ultra-High-Temperature Furnaces

- What are the advantages of using a quartz tube for high-temp dielectric measurements? Optimize Accuracy & Stability

- What functions do high-purity sulfur powder and ceramic boats serve in TB-MoS2 prep? Precision in 2D Material Synthesis

- What is lab vacuum used for? Mastering Environmental Control for Purity and Precision

- Why are high-purity alumina grinding balls used for Al2O3/TiC milling? Master Chemical Consistency