In quality control, laboratory furnaces serve as the definitive test environment for validating the thermal integrity of materials and finished products. They function by subjecting samples to precisely controlled, often extreme, temperatures. This process simulates real-world conditions to uncover hidden weaknesses, verify material specifications, and ensure a product can perform safely and reliably throughout its intended lifecycle.

A laboratory furnace is not merely a heating device; it is a critical instrument for proactive quality assurance. It allows you to simulate a product's entire thermal journey—from manufacturing stress to end-use failure—to identify and correct potential defects before they ever reach the market.

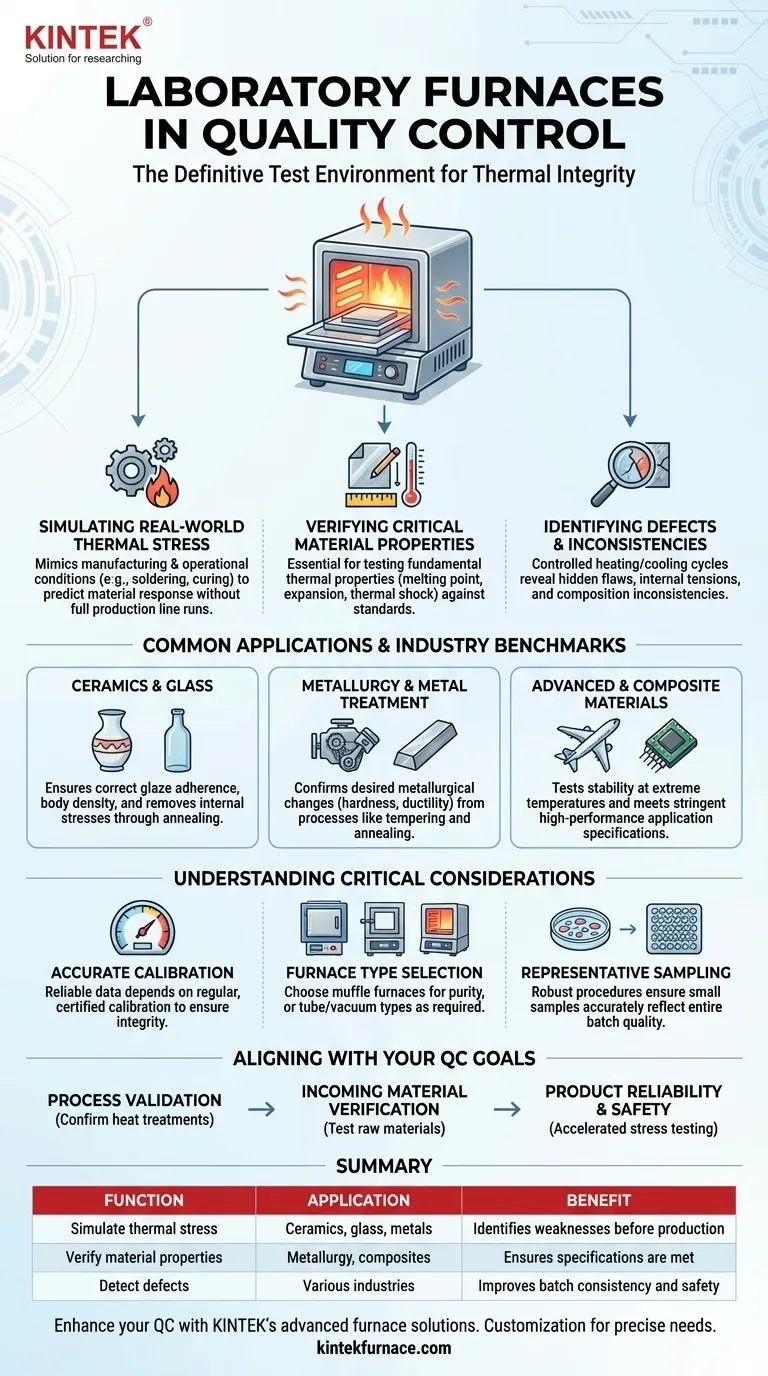

How Furnaces Enable Rigorous Quality Control

The core function of a laboratory furnace in a QC setting is to provide a stable, repeatable, and precisely controlled thermal environment. This capability is the foundation for several critical testing methodologies.

Simulating Real-World Thermal Stress

Many products are exposed to high temperatures during either their manufacturing process or their operational life. A laboratory furnace accurately mimics these conditions on a small, controlled scale.

This allows quality technicians to observe how a material or component responds to processes like soldering, heat treatment, or curing without having to run a full production line.

Verifying Critical Material Properties

A furnace is essential for testing fundamental thermal properties against established standards. This includes determining a material's melting point, thermal expansion coefficient, or its resistance to thermal shock.

By performing these tests, you can confirm that a batch of raw material—be it metal, ceramic, or polymer—matches the required specifications before it is used in production.

Identifying Defects and Inconsistencies

Controlled heating and cooling cycles can reveal flaws that are otherwise invisible. Exposing a material to thermal stress can expose internal tensions in glass, weak points in a solder joint, or inconsistencies in a ceramic's composition.

This process is vital for ensuring batch-to-batch consistency and catching defects early, preventing widespread product failures.

Common Applications in Quality Control

The versatility of laboratory furnaces makes them indispensable across numerous industries, each with unique quality benchmarks.

Ceramics and Glass Manufacturing

In ceramics, furnaces are used to test the firing process, ensuring glazes adhere correctly and the body of the ceramic achieves its required density and strength.

For glass, a process called annealing—heating and then slowly cooling the material—is simulated in a lab furnace to verify that internal stresses have been properly removed, preventing future shattering.

Metallurgy and Metal Treatment

Heat treatment is fundamental to achieving desired properties like hardness or ductility in metals. A laboratory furnace is used to test samples and confirm that production-level processes like tempering, hardening, or annealing are producing the intended metallurgical changes.

This ensures that a metal component, such as an engine part or a structural beam, possesses the exact mechanical properties required for its application.

Advanced and Composite Materials

When developing new materials like technical ceramics or advanced composites, furnaces are crucial for both research and quality control.

They are used to test the material's stability at extreme temperatures and to ensure the final product meets the stringent specifications required for high-performance applications, from aerospace components to electronics.

Understanding the Trade-offs and Considerations

While essential, the effective use of a laboratory furnace requires an understanding of its limitations and operational requirements.

The Importance of Accurate Calibration

The data from a furnace is only as reliable as the furnace itself. Inaccurate temperature controllers or faulty thermocouples can render QC tests meaningless, potentially leading to the approval of substandard materials.

Regular, certified calibration is not an optional maintenance step; it is fundamental to the integrity of the entire quality control process.

Muffle Furnaces vs. Other Types

The term "laboratory furnace" often refers to a muffle furnace, which uses an external heating element to heat an inner chamber, or "muffle." This prevents combustion byproducts from contaminating the sample.

This is ideal for applications requiring high purity, like ashing or chemical analysis. However, for other applications, different furnace types like tube or vacuum furnaces may be more appropriate. Choosing the right tool is critical.

The Challenge of Representative Sampling

A laboratory furnace can only test a small sample. A primary challenge in QC is ensuring that this small sample is truly representative of the entire production batch.

A robust sampling procedure is necessary to ensure the results from the furnace test accurately reflect the quality of the entire lot.

Aligning Furnace Use with Your QC Goals

To maximize the value of a laboratory furnace, tailor its application to your specific quality control objective.

- If your primary focus is process validation: Use the furnace to confirm that your production heat treatments (like annealing or tempering) are consistently achieving the desired material transformations.

- If your primary focus is incoming material verification: Use the furnace to test samples of raw materials upon arrival to ensure they meet thermal specifications before they enter the production workflow.

- If your primary focus is product reliability and safety: Use the furnace to perform accelerated stress testing, simulating extreme end-use conditions to identify potential failure points long before the product reaches the customer.

Ultimately, a laboratory furnace transforms quality control from a reactive measure into a proactive strategy for guaranteeing material integrity and product excellence.

Summary Table:

| Function | Application | Benefit |

|---|---|---|

| Simulate thermal stress | Ceramics, glass, metals | Identifies weaknesses before production |

| Verify material properties | Metallurgy, composites | Ensures specifications are met |

| Detect defects | Various industries | Improves batch consistency and safety |

Ready to enhance your quality control with advanced furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to discuss how we can support your material testing and reliability goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition