The primary advantage of a two-color pyrometer is its ability to deliver precise temperature readings by measuring the ratio of radiant energy at two distinct wavelengths. unlike standard devices that measure absolute intensity, this method effectively cancels out errors caused by signal attenuation, making it the superior choice for harsh, ultra-high-temperature environments.

Core Takeaway: In furnace environments reaching 1650°C, traditional measurement methods often fail due to physical obstructions or fluctuating material properties. A two-color pyrometer solves this by relying on the ratio of wavelengths rather than total signal strength, ensuring reliable process control even when the optical path is obscured by dust, smoke, or dirty windows.

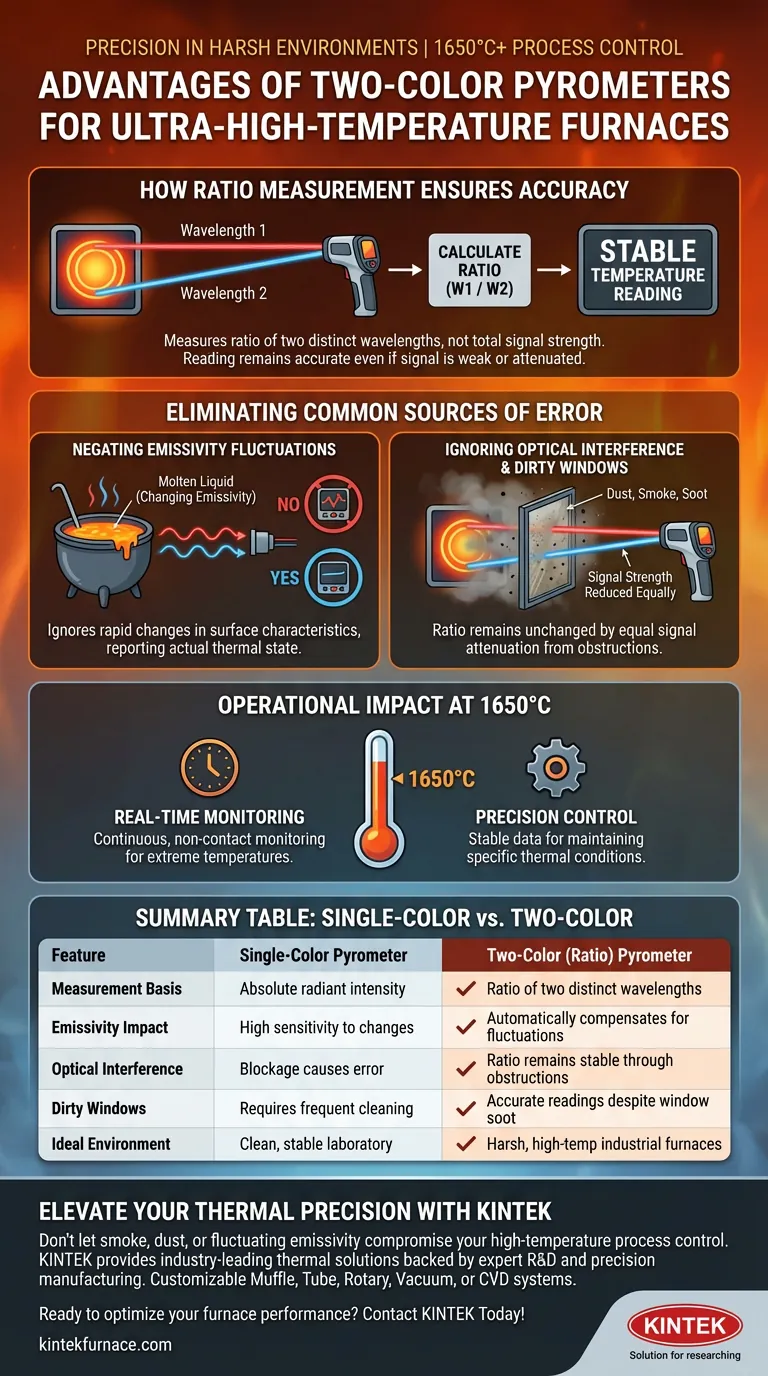

How Ratio Measurement Ensures Accuracy

Measuring Distinct Wavelengths

Standard pyrometers rely on the total amount of energy received to calculate temperature. A two-color pyrometer, however, simultaneously measures radiant energy at two separate wavelengths.

The Stability of the Ratio

The device determines the temperature by calculating the ratio between these two measurements. Because the temperature calculation is based on this relationship rather than raw signal strength, the reading remains stable even if the total signal is weak.

Eliminating Common Sources of Error

Negating Emissivity Fluctuations

In molten liquid processing, the emissivity (the efficiency with which a surface emits energy) of the material can change rapidly. Standard sensors interpret these changes as temperature shifts, leading to false data.

Solving the "Changing Surface" Problem

A two-color pyrometer effectively eliminates errors caused by changes in surface emissivity. This ensures that the reported temperature reflects the actual thermal state of the molten liquid, not just its surface characteristics.

Ignoring Optical Interference

Ultra-high-temperature furnaces are notoriously dirty environments, often filled with smoke, dust, or steam. Furthermore, the viewing windows used to observe the process frequently become coated with soot or debris.

Seeing Through Obstructions

Because dust and window dirt typically reduce the signal strength of both wavelengths equally, the ratio remains unchanged. This allows the pyrometer to provide accurate, non-contact readings even through a dirty window or a smoky atmosphere.

Operational Impact at 1650°C

Real-Time Monitoring

At extreme temperatures like 1650°C, contact sensors are often impractical or short-lived. Two-color pyrometry provides a highly reliable non-contact method for continuous monitoring.

Precision Control

The ability to ignore environmental interference allows for precise real-time control of the furnace. This stability is critical for maintaining the specific thermal conditions required for processing molten liquids.

Context and Considerations

Specialized for Extremes

While highly effective, this technology is specifically optimized for environments where signal attenuation is a known problem. It is designed to overcome barriers that render single-color pyrometers inaccurate.

Non-Contact Limitations

It is important to remember that while the device can see through interference, it still requires a line of sight to the target. It is an optical instrument designed to interpret radiant energy, not a physical probe.

Making the Right Choice for Your Goal

To determine if a two-color pyrometer is the right solution for your specific furnace application, consider the following:

- If your primary focus is handling dirty environments: Use this technology to bypass errors caused by dust, smoke, or soot accumulating on your viewing windows.

- If your primary focus is molten metal stability: Choose this device to ensure accurate readings despite the constantly changing emissivity of the liquid surface.

- If your primary focus is extreme temperature longevity: Rely on this non-contact method to monitor 1650°C+ heat without subjecting sensors to physical degradation.

By decoupling temperature measurement from signal intensity, the two-color pyrometer turns a volatile, variable environment into a source of consistent, actionable data.

Summary Table:

| Feature | Single-Color Pyrometer | Two-Color (Ratio) Pyrometer |

|---|---|---|

| Measurement Basis | Absolute radiant intensity | Ratio of two distinct wavelengths |

| Emissivity Impact | High sensitivity to changes | Automatically compensates for fluctuations |

| Optical Interference | Blockage (dust/smoke) causes error | Ratio remains stable through obstructions |

| Dirty Windows | Requires frequent cleaning | Accurate readings despite window soot |

| Ideal Environment | Clean, stable laboratory settings | Harsh, high-temp industrial furnaces |

Elevate Your Thermal Precision with KINTEK

Don't let smoke, dust, or fluctuating emissivity compromise your high-temperature process control. KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing.

Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our lab high-temp furnaces are fully customizable to meet your unique research and production needs. Our specialized expertise ensures that your ultra-high-temperature operations remain stable, accurate, and efficient.

Ready to optimize your furnace performance? Contact KINTEK Today to Consult with Our Experts

Visual Guide

References

- Hyunjae Kim, Youn‐Bae Kang. Evaporation of Sn from Molten Fe–C–S Alloy Under Reduced Pressure at 1650 $$^\circ $$C for Developing Sustainable Ferrous Scrap Recycling Process. DOI: 10.1007/s11663-025-03579-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- What types of high-temperature laboratory furnace systems are available? Explore 5 Specialized Solutions

- What are the technical advantages of using a quartz tube as a reaction chamber? Optimize g-C3N4 Thin Film CVD Processes

- Why is a high-vacuum extraction system used to reach 10⁻² Pa inside composite billets? Ensure Superior Metal Bonding

- What is the primary function of an alumina crucible in preparing B2O3–ZnO–BaO shielding glass? Process Secrets Revealed

- How does a precision Mass Flow Controller (MFC) regulate argon carrier gas to affect the growth of WS2 nanosheets?

- What is the function of an enhanced hydrothermal reactor with magnetic stirring? Optimize MoS2/C Synthesis Yield

- What factors should be considered when selecting an alumina ceramic furnace tube? Ensure Safety and Performance in High-Temp Processes

- How does a high-performance temperature controller contribute to repeatability? Precision for FTO Thin Film Annealing