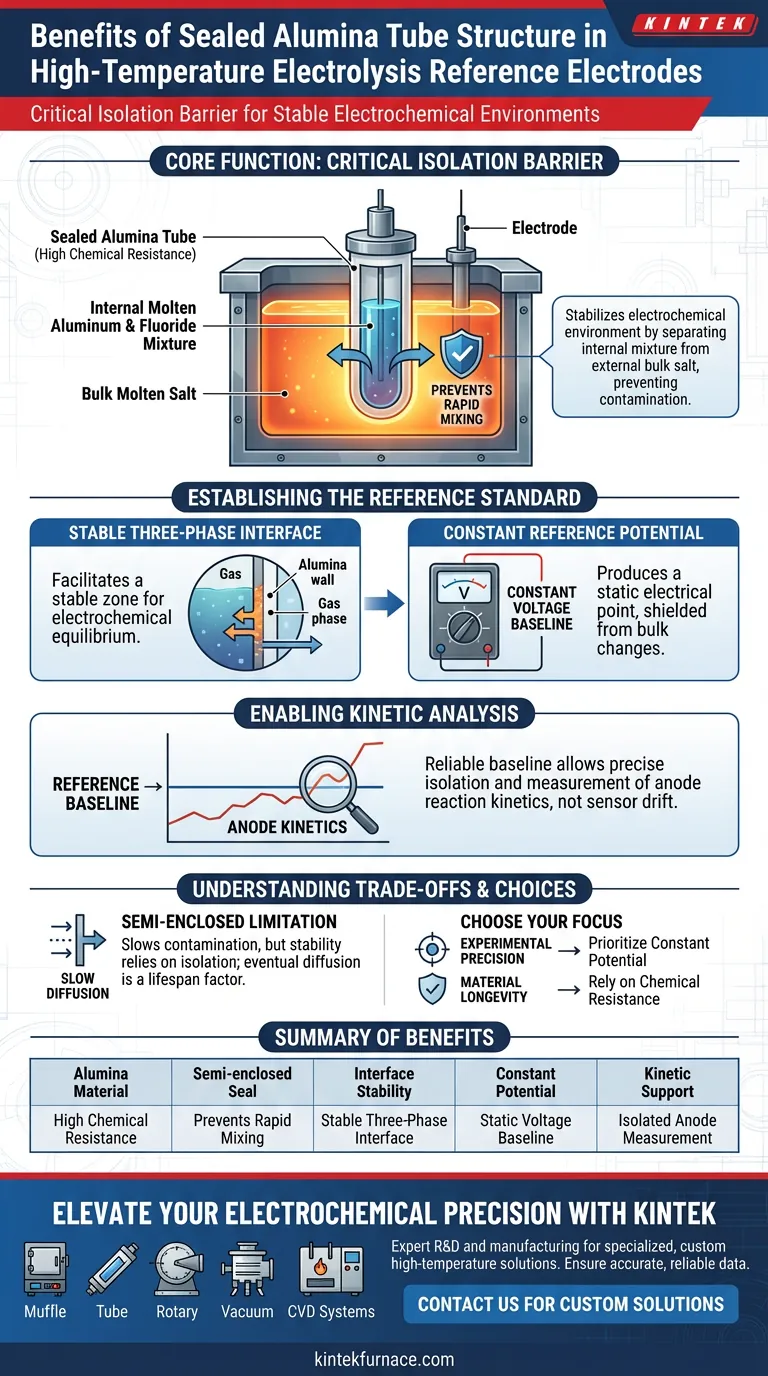

The sealed Alumina Tube structure functions as a critical isolation barrier that stabilizes the electrochemical environment within high-temperature electrolysis systems. By physically separating the internal molten aluminum and fluoride mixture from the external bulk molten salt, this design prevents contamination and ensures the generation of a consistent reference potential.

Core Takeaway The primary benefit of the sealed Alumina Tube is the creation of a stable "three-phase interface" through physical and chemical isolation. By leveraging alumina’s resistance to prevent rapid fluid mixing, the device maintains the constant voltage baseline required to accurately measure the kinetic parameters of the anode.

The Mechanics of Isolation and Stability

Leveraging Chemical Resistance

The foundation of this design is the material choice: alumina.

This material possesses high chemical resistance, allowing the tube to withstand the harsh conditions of high-temperature electrolysis without degrading. This structural integrity is essential for protecting the internal components of the reference electrode.

Prevention of Rapid Mixing

The structure is described as a "semi-enclosed" design.

Its primary mechanical function is to prevent the internal mixture (molten aluminum and fluoride) from mixing rapidly with the bulk molten salt outside the tube. Without this barrier, the internal electrolyte would dilute or react with the bulk fluid, destroying the reference baseline immediately.

Establishing the Reference Standard

The Three-Phase Interface

The containment provided by the alumina tube facilitates a stable three-phase interface.

This interface serves as the specific zone where the necessary electrochemical equilibrium occurs. Stability here is non-negotiable; if this interface fluctuates due to turbulence or mixing, the reading becomes useless.

Generating a Constant Potential

Because the internal mixture is shielded from rapid changes in the bulk environment, the electrode produces a constant reference potential.

This constancy is the defining characteristic of a functional reference electrode. It provides a static electrical point against which other changing potentials can be measured.

Enabling Kinetic Analysis

A Reliable Baseline for Measurement

The ultimate benefit of this design is its ability to support precise data collection.

By providing a stable voltage floor, the electrode allows researchers to isolate and measure the kinetic parameters of the anode electrode process. Variations in voltage can be attributed to the anode's reaction kinetics rather than instability in the reference tool itself.

Understanding the Trade-offs

The "Semi-Enclosed" Limitation

While the text highlights the prevention of rapid mixing, the design is described as "semi-enclosed" rather than hermetically sealed.

This implies that while the design drastically slows down contamination, it may not prevent it indefinitely over very long durations. The stability of the potential relies on this isolation; therefore, any eventual diffusion across the interface represents the limiting factor of the electrode's lifespan.

Making the Right Choice for Your Goal

To maximize the effectiveness of your electrolysis setup, consider how this design aligns with your specific constraints:

- If your primary focus is experimental precision: Prioritize this design for its ability to maintain a constant potential, ensuring that your kinetic data reflects the anode process, not sensor drift.

- If your primary focus is material longevity: Rely on the high chemical resistance of the alumina tube to protect the internal electrolyte mixture from the harsh bulk salt environment.

The sealed Alumina Tube structure transforms a volatile high-temperature environment into a controlled setting, providing the stability necessary for accurate electrochemical analysis.

Summary Table:

| Feature | Benefit for Reference Electrode |

|---|---|

| Alumina Material | High chemical resistance against harsh bulk molten salts |

| Semi-enclosed Seal | Prevents rapid mixing to maintain internal electrolyte purity |

| Interface Stability | Facilitates a stable three-phase interface for equilibrium |

| Constant Potential | Provides a static voltage baseline for precise anode measurement |

| Kinetic Support | Enables isolated measurement of anode reaction kinetics |

Elevate Your Electrochemical Precision with KINTEK

Don't let sensor drift compromise your high-temperature research. Backed by expert R&D and manufacturing, KINTEK offers a wide range of specialized solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which can be customized for your unique high-temperature electrolysis needs.

Whether you are conducting delicate kinetic analysis or scaling up industrial processes, our lab furnaces provide the stable thermal environment your reference electrodes require to perform at their peak. Contact us today to find your custom solution and ensure your data remains accurate and reliable.

Visual Guide

References

- Kamaljeet Singh, Guðrún Sævarsdóttir. Overpotential on Oxygen-Evolving Platinum and Ni-Fe-Cu Anode for Low-Temperature Molten Fluoride Electrolytes. DOI: 10.1007/s11837-024-06425-5

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is modified PTFE used as a liner in high-pressure reactors for MoS2/C? Enhancing Purity and Yield.

- What is the function of condensers and cold traps in VEA? Master Efficient Reagent Recovery and Closed-Loop Success

- What is the importance of using a Mass Flow Controller (MFC)? Enhance Molybdenum Phosphide (MoP) Synthesis Precision

- What information does laboratory XRD provide for Gallium Sulfide? Master GaS Single Crystal Characterization

- What are the benefits of 150mm thick ceramic fiber blankets in furnaces? Boost Efficiency and Safety

- What role do substrate heaters play in Ga2O3:Er thin films? Unlock Crystalline Beta-Phase Transitions

- What advantages do platinum crucibles offer for KCdCl3 sintering? Ensure Pure, Single-Phase Sample Synthesis

- What factors affect the light transmittance of alumina tubes? Balance Clarity and Durability for Your Lab