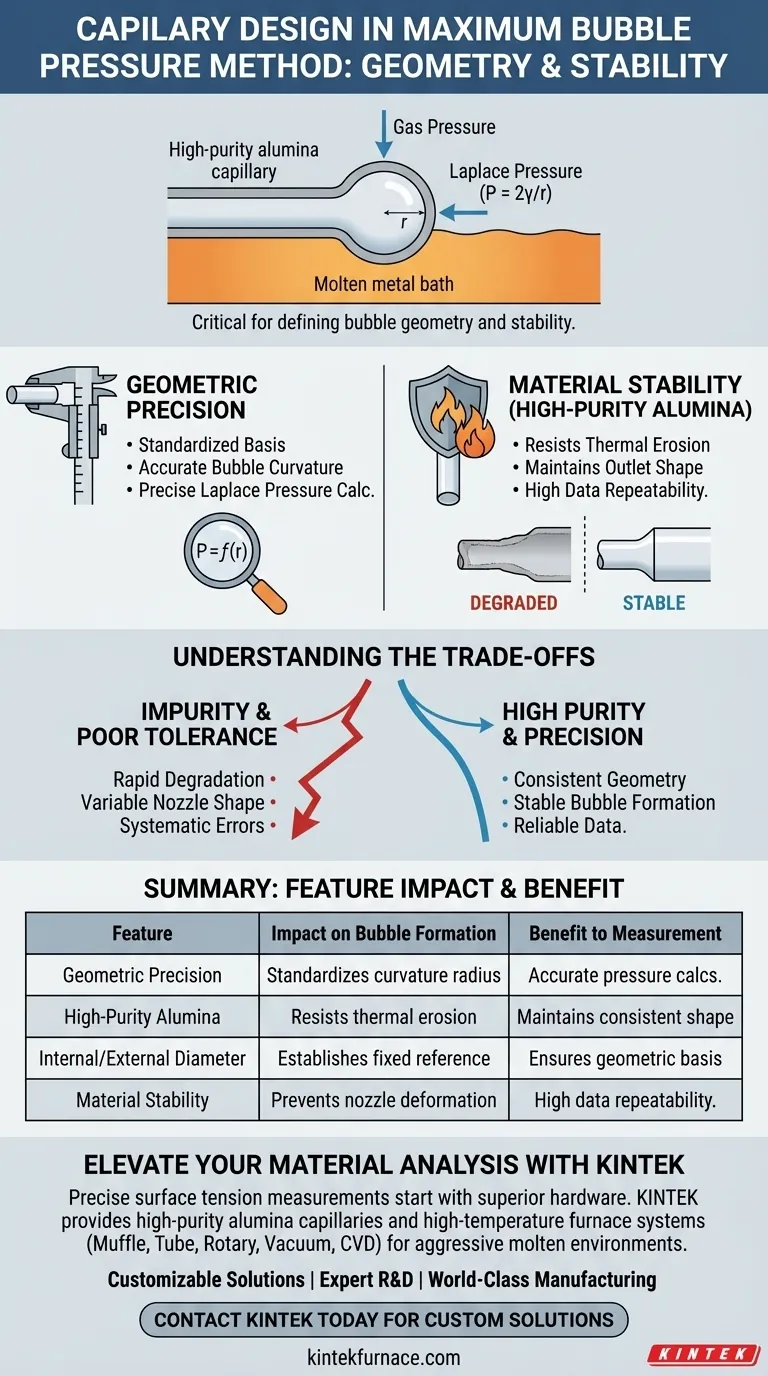

The design of high-purity alumina capillaries is the critical factor in defining the geometry and stability of bubble formation during measurement. By maintaining precise internal and external diameters and resisting high-temperature erosion, these capillaries ensure the bubble curvature radius remains constant, which is essential for accurate Laplace pressure calculations.

In the maximum bubble pressure method, measurement reliability depends entirely on the stability of the nozzle geometry. High-purity alumina prevents physical degradation in molten environments, ensuring that the standardized geometric basis required for calculating surface tension remains consistent over time.

The Role of Geometric Precision

Establishing a Standardized Basis

The capillary acts as the physical reference for the entire measurement system. Precise internal and external diameters provide the standardized geometric basis necessary for the method to work.

Calculating Bubble Curvature

To derive accurate surface tension data, you must calculate the radius of the bubble's curvature. This calculation relies directly on the fixed dimensions of the capillary tip.

Ensuring Pressure Accuracy

The Laplace pressure—the pressure difference across the bubble interface—is a function of the bubble's radius. If the capillary design lacks precision, the pressure readings will not correlate accurately with the surface tension of the melt.

Material Stability in Extreme Conditions

Resisting Thermal Erosion

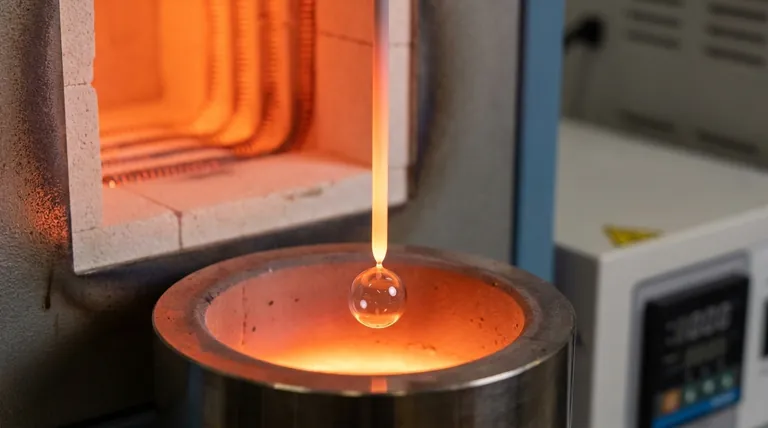

Molten metals, such as steel, create an aggressive environment that can rapidly degrade standard materials. High-purity alumina is specifically utilized for its resistance to this high-temperature erosion.

Maintaining Outlet Shape

For the measurement to be repeatable, the nozzle outlet must not change shape as bubbles emerge. Alumina's resistance ensures the outlet does not widen or deform during the process.

Improving Data Repeatability

When the nozzle shape remains constant, every bubble forms under identical geometric constraints. This stability is the primary driver for high repeatability in surface tension calculations.

Understanding the Trade-offs

The Cost of Impurity

Using capillaries that lack high purity introduces a risk of rapid degradation. If the material erodes, the nozzle outlet shape changes effectively immediately, rendering subsequent measurements incomparable.

Dependency on Manufacturing Tolerances

The method is highly sensitive to the initial manufacturing quality of the capillary. Even with high-purity material, a lack of precise diameter control during the capillary's production will lead to systematic errors in the Laplace pressure calculation.

Making the Right Choice for Your Goal

To ensure valid data in the maximum bubble pressure method, you must select capillaries that align with the rigorous demands of the environment.

- If your primary focus is Calculation Accuracy: Ensure the capillary features precise, verified internal and external diameters to establish a correct baseline for bubble curvature.

- If your primary focus is Data Repeatability: Prioritize high-purity alumina grades to prevent erosion and maintain a constant nozzle outlet shape throughout the measurement series.

The integrity of your surface tension calculations is directly proportional to the geometric and thermal stability of the capillary you employ.

Summary Table:

| Feature | Impact on Bubble Formation | Benefit to Measurement |

|---|---|---|

| Geometric Precision | Standardizes bubble curvature radius | Accurate Laplace pressure calculations |

| High-Purity Alumina | Resists thermal erosion in molten metals | Maintains consistent nozzle shape over time |

| Internal/External Diameter | Establishes a fixed physical reference | Ensures standardized geometric basis |

| Material Stability | Prevents nozzle deformation | High data repeatability and reliability |

Elevate Your Material Analysis with KINTEK

Precise surface tension measurements start with superior hardware. KINTEK provides high-purity alumina capillaries and high-temperature furnace systems designed to withstand the most aggressive molten environments.

Backed by expert R&D and world-class manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your specific research or industrial requirements. Ensure the integrity of your data with components built for thermal stability and geometric precision.

Ready to optimize your lab's performance? Contact KINTEK today to discuss your custom high-temperature solutions.

Visual Guide

References

- Lukas Neubert, Olena Volkova. Effect of Oxygen on Thermophysical Properties of Molten High-Silicon Electrical Steels and Its Impact on Bubble Formation Behavior. DOI: 10.1007/s11663-025-03594-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What role do vacuum pumps and chambers play in the Reduced Pressure Test? Mastering Aluminum Quality Control

- Is there a need to add water when launching the circulating water multifunctional vacuum pump? Ensure Optimal Performance and Avoid Damage

- Why is a PTFE-lined stainless steel autoclave used for Ni12P5 synthesis? Key Benefits for Nanomaterial Production

- How does a laboratory blast drying oven facilitate BCZT gel drying? Precision Solutions for High-Quality Xerogels

- What are the power specifications for a typical circulating water vacuum pump? Key Specs for Lab Efficiency

- What material are quartz tubes made from and what temperature can they withstand? Discover High-Temp Solutions for Your Lab

- How does a laboratory blast drying oven facilitate the treatment of Au/ZnO/In2O3 precursor precipitates? Key Benefits

- How are quartz tubes used in laboratory applications? Essential for High-Temp, High-Purity Processes