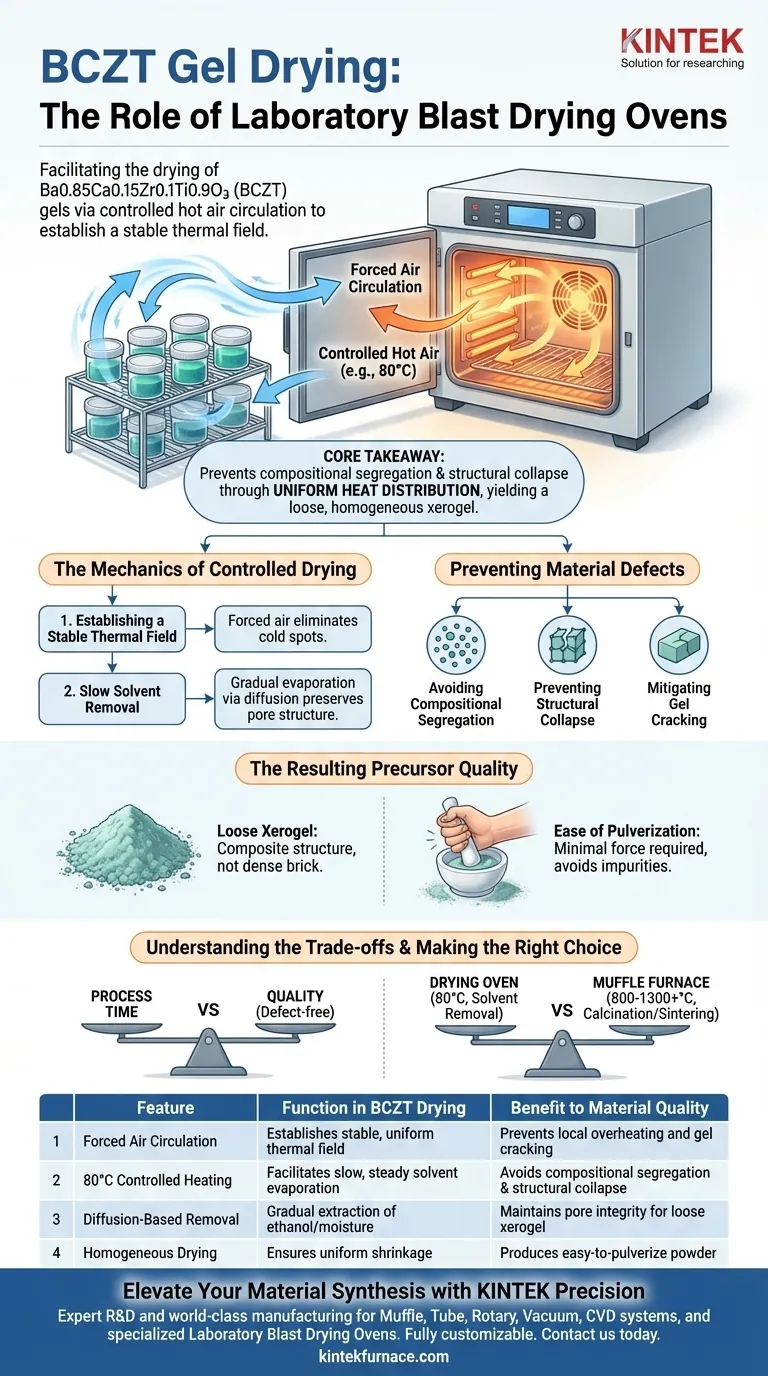

The laboratory blast drying oven facilitates the drying of BCZT gels by utilizing controlled hot air circulation to establish a stable thermal field. This environment ensures the slow, uniform removal of residual solvents (specifically ethanol) and moisture from the gel matrix. By maintaining a steady temperature, typically around 80 °C, the oven transforms the wet gel into a loose xerogel precursor without triggering the structural defects associated with rapid evaporation.

Core Takeaway The primary value of the blast drying oven is its ability to prevent compositional segregation and structural collapse through uniform heat distribution. This controlled process yields a loose, homogeneous xerogel that is chemically stable and easily pulverized for subsequent calcination.

The Mechanics of Controlled Drying

Establishing a Stable Thermal Field

The "blast" function of the oven refers to forced air circulation. This ensures that thermal energy is distributed evenly throughout the chamber, eliminating cold spots. For BCZT gels, a stable temperature (often set at 80 °C) is critical to facilitate the complete evaporation of solvents like ethanol without subjecting the material to thermal shock.

Slow Solvent Removal

The oven is designed to remove volatiles gradually rather than instantaneously. Rapid boiling of solvents within the gel can destroy the delicate pore structure. By drying slowly, the oven allows solvents to escape via diffusion, maintaining the integrity of the material's framework.

Preventing Material Defects

Avoiding Compositional Segregation

BCZT is a complex mixture involving Barium, Calcium, Zirconium, and Titanium. Rapid local evaporation can cause these distinct components to separate or precipitate unevenly. The drying oven’s uniform heat ensures that the molecular-level mixing achieved during the sol-gel synthesis is preserved as the liquid phase is removed.

Preventing Structural Collapse

If solvents volatilize too quickly, the capillary forces inside the gel pores can become extreme, leading to the collapse of the structure. The drying oven mitigates this by keeping evaporation rates within a safe, controlled range.

Mitigating Gel Cracking

Non-uniform heating causes differential expansion and contraction, leading to physical cracking of the gel. The air circulation in the blast oven prevents local overheating, ensuring the gel shrinks uniformly as it dries.

The Resulting Precursor Quality

Formation of Loose Xerogel

The ultimate output of this process is a "xerogel"—a solid gel with the liquid removed. Because the drying was controlled, this material does not form a hard, dense brick. Instead, it results in a "loose" composite structure.

Ease of Pulverization

The loose nature of the dried xerogel is a significant processing advantage. It requires minimal mechanical force to grind down. This ease of pulverization prevents the need for aggressive milling, which could introduce impurities or heat stress before the calcination stage.

Understanding the Trade-offs

Process Time vs. Quality

The primary trade-off in using a laboratory drying oven is time. To achieve a defect-free xerogel, the process must be slow. Rushing this stage by increasing the temperature significantly above 80 °C to save time risks forming hard agglomerates or inducing component segregation.

Temperature Limitations

It is important to distinguish the drying oven from a muffle furnace. The drying oven is strictly for solvent removal (up to ~200-300 °C, though used here at 80 °C). It cannot perform the pre-calcination (oxidative removal of organics at ~800 °C) or sintering (densification at ~1300+ °C). Attempting high-temperature reactions in a drying oven is unsafe and ineffective.

Making the Right Choice for Your Goal

To maximize the quality of your BCZT ceramics, apply the drying process strategically:

- If your primary focus is chemical homogeneity: maintain the oven strictly at 80 °C to ensure solvents evaporate without disturbing the distribution of metal ions.

- If your primary focus is ease of grinding: ensure the drying cycle is long enough to fully remove moisture, resulting in a loose powder that resists hard agglomeration.

The laboratory blast drying oven serves as the critical bridge between liquid-phase synthesis and solid-state reaction, safeguarding the chemical uniformity required for high-performance piezoelectric materials.

Summary Table:

| Feature | Function in BCZT Drying | Benefit to Material Quality |

|---|---|---|

| Forced Air Circulation | Establishes a stable, uniform thermal field | Prevents local overheating and gel cracking |

| 80 °C Controlled Heating | Facilitates slow, steady solvent evaporation | Avoids compositional segregation and structural collapse |

| Diffusion-Based Removal | Gradual extraction of ethanol/moisture | Maintains pore integrity for a loose xerogel structure |

| Homogeneous Drying | Ensures uniform shrinkage of the gel matrix | Produces a powder that is easy to pulverize for calcination |

Elevate Your Material Synthesis with KINTEK Precision

Precise thermal control is the difference between a failed sample and a high-performance piezoelectric ceramic. Backed by expert R&D and world-class manufacturing, KINTEK provides a comprehensive range of laboratory equipment including Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized Laboratory Blast Drying Ovens.

Our systems are fully customizable to meet your unique research needs, ensuring the chemical homogeneity and structural integrity of your BCZT gels and other advanced materials.

Ready to optimize your drying and sintering workflows? Contact our technical experts today to find the perfect high-temperature solution for your lab.

Visual Guide

References

- Baoyun Wang, Yongjun Tian. High-temperature structural disorders stabilize hydrous aluminosilicates in the mantle transition zone. DOI: 10.1038/s41467-025-56312-z

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a quartz tube reaction chamber play during the Carbon Thermal Shock (CTS) process? Essential Performance

- What is the function of a honeycomb-shaped firing tray? Master Thermal Equilibrium in Ceramic Sintering

- Why are coating samples placed in specialized crucibles? Ensure Accurate Molten Salt Corrosion Testing Results

- Which is better graphite or ceramic crucible? Match Your Material & Process for Optimal Melting

- Why is molybdenum (Mo) selected as the crucible material for the evaporation of NiO-doped Ga2O3? Expert Insights

- What is the purpose of an ultrasonic cleaner in NiMo@Cx catalyst prep? Achieve Uniform Slurry & High-Porosity Coatings

- What is the critical physical function of a laboratory electric blast drying oven in phosphor gel treatment?

- Why use a covered crucible for g-C3N4 calcination? Enhance Surface Area via Self-Exfoliation