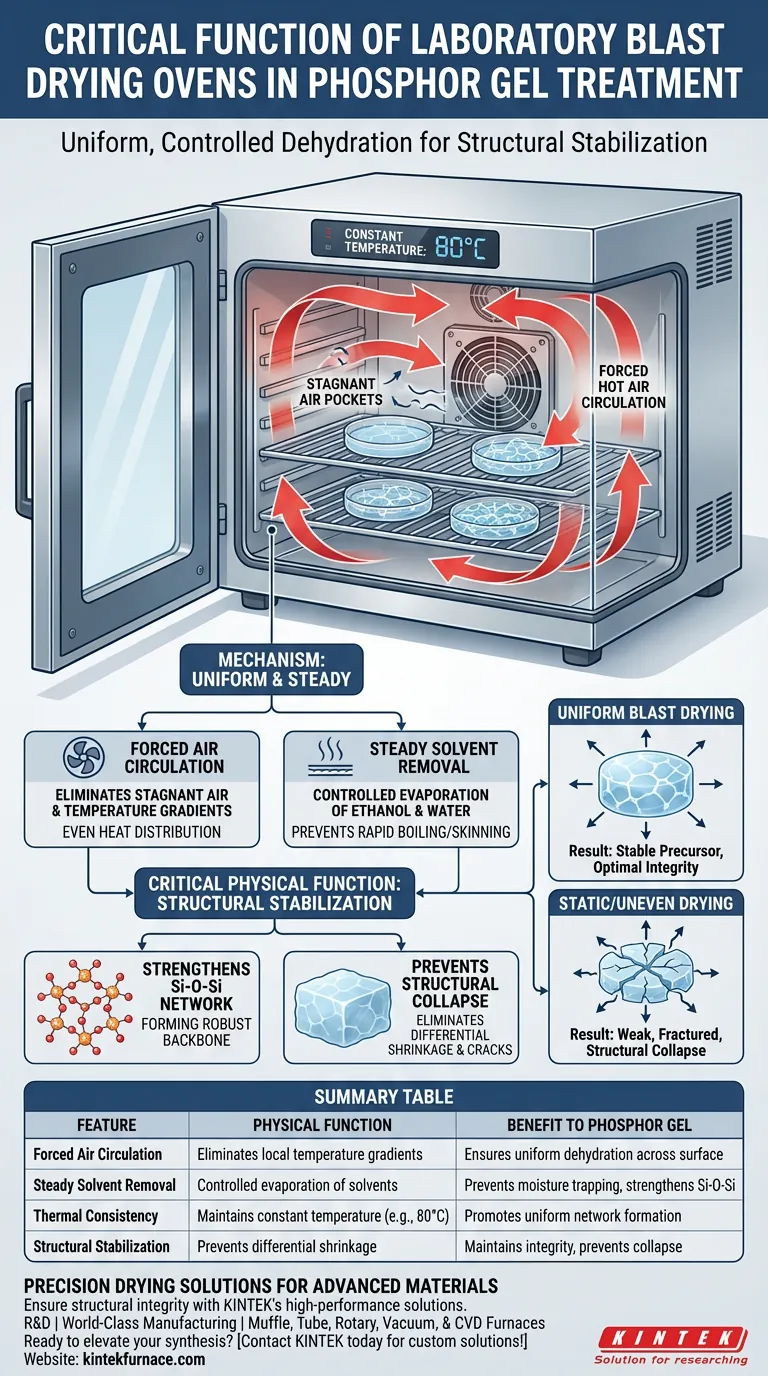

The critical physical function of a laboratory electric blast drying oven is to execute a uniform, controlled dehydration process that stabilizes the gel’s internal structure prior to high-temperature synthesis. By utilizing forced hot air circulation at a constant temperature (typically 80°C), the oven steadily removes residual ethanol and excess water while actively preventing the physical defects associated with uneven drying.

Core Takeaway Drying is not merely about solvent removal; it is a structural stabilization step. The blast drying oven ensures the Si-O-Si network strengthens uniformly, preventing the structural collapse that often results from local temperature gradients during static drying.

The Mechanism of Controlled Dehydration

Forced Hot Air Circulation

The defining feature of a "blast" oven is its ability to circulate heated air actively. This mechanism ensures that heat is distributed evenly across the entire surface area of the gel.

Without this forced circulation, stagnant air pockets can create uneven drying rates. The blast function guarantees that the thermal environment remains consistent throughout the chamber.

Steady Solvent Removal

The gel treatment process requires the removal of volatile components, specifically residual ethanol and excess water.

The oven operates at a constant temperature to drive these solvents out at a steady, predictable rate. This controlled evaporation prevents the rapid boiling or skinning that might trap moisture inside the material.

Structural Stabilization of the Precursor

Strengthening the Si-O-Si Network

As the solvents are removed, the chemical structure of the gel evolves. The steady heat promotes the further condensation and strengthening of the Si-O-Si (silicon-oxygen-silicon) network.

This network is the backbone of the precursor. Ensuring it forms correctly during this low-temperature phase is vital for the material's performance in later stages.

Preventing Structural Collapse

The most critical protective function of the oven is the prevention of structural collapse.

In uneven heating environments, local temperature gradients cause different parts of the gel to shrink at different rates. This differential shrinkage leads to cracks and collapse. The blast oven’s uniform heat profile eliminates these gradients, maintaining the precursor's ideal physical form.

Understanding the Trade-offs

The Risk of Non-Uniformity

If the forced air circulation is interrupted or the oven is overloaded, the uniformity of the process is compromised.

Even a slight variance in airflow can reintroduce temperature gradients. This defeats the purpose of the equipment, potentially leading to a weak or fractured Si-O-Si network despite the correct temperature setting.

Temperature Precision vs. Speed

While it may be tempting to increase temperatures to speed up drying, the process relies on a constant, moderate temperature (e.g., 80°C).

Excessive heat can drive solvents off too violently, damaging the pore structure before the network has time to rigidify. The goal is stability, not speed.

Making the Right Choice for Your Goal

To maximize the effectiveness of the gel treatment process, prioritize the following parameters:

- If your primary focus is Structural Integrity: Ensure the oven's airflow vents are unobstructed to guarantee the uniform dehydration required to prevent collapse.

- If your primary focus is Chemical Purity: Monitor the duration of the cycle to ensure the complete removal of ethanol and water, which facilitates the optimal strengthening of the Si-O-Si network.

A stable, uniformly dried precursor is the prerequisite for high-performance phosphor production.

Summary Table:

| Feature | Physical Function | Benefit to Phosphor Gel |

|---|---|---|

| Forced Air Circulation | Eliminates local temperature gradients | Ensures uniform dehydration across the entire gel surface |

| Steady Solvent Removal | Controlled evaporation of ethanol and water | Prevents rapid boiling and moisture trapping |

| Thermal Consistency | Constant temperature maintenance (e.g., 80°C) | Strengthens the Si-O-Si network backbone |

| Structural Stabilization | Prevention of differential shrinkage | Maintains precursor integrity and prevents structural collapse |

Precision Drying Solutions for Advanced Materials

Ensure the structural integrity of your precursors with KINTEK’s high-performance laboratory solutions. Backed by expert R&D and world-class manufacturing, we provide high-precision electric blast drying ovens and specialized high-temperature systems including Muffle, Tube, Rotary, Vacuum, and CVD furnaces.

Whether you are stabilizing delicate Si-O-Si networks for phosphor production or require a fully customizable thermal process for unique lab needs, KINTEK delivers the reliability and uniform heat control your research demands.

Ready to elevate your material synthesis? Contact KINTEK today to find your custom solution!

Visual Guide

References

- K. A. K. Durga Prasad, D. Haranath. Enhanced blue emission and afterglow properties of Sr2MgSi2O7:Eu2+, Dy3+ phosphors for flexible transparent labels. DOI: 10.1063/5.0230526

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the primary functions of a self-preheating heat exchanger? Maximize Thermal Efficiency in Double-P Tubes

- What are the advantages of using a single-mode microwave generator? Precision Heating for Metal Recovery

- How does a laboratory drying oven function in catalyst synthesis? Secure Precision Metal Precursor Stabilization

- What is the role of a high-temperature ceramic boat during phosphidation? Ensure Pure and Stable Chemical Synthesis

- What cost factors should be considered when choosing an alumina ceramic furnace tube? Optimize Total Cost of Ownership

- Why is a vacuum drying oven necessary for Al2O3/TiC ceramic powders? Ensure Purity and Prevent Agglomeration

- What is the role of a Teflon-lined autoclave in CQD synthesis? Master Hydrothermal Carbonization for Precision Carbon Dots

- What environmental conditions do vacuum systems and quartz tubes provide? Optimize ZnS Nanobelt Synthesis