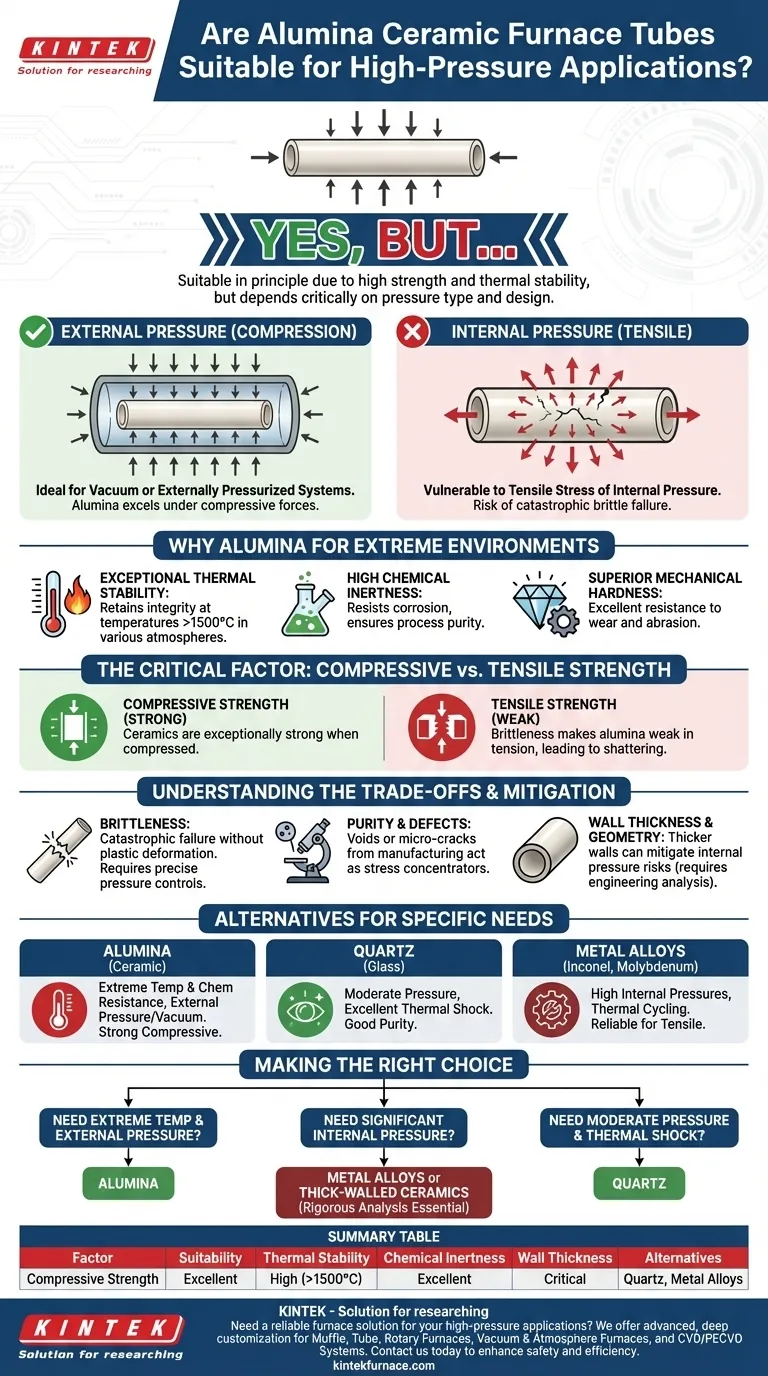

In principle, yes, alumina ceramic furnace tubes can be used for high-pressure applications due to their excellent mechanical strength and thermal stability. However, their suitability is not absolute and depends entirely on the specific operating conditions, particularly the nature of the pressure and the tube's design specifications.

While alumina excels under compressive forces, making it ideal for vacuum or externally pressurized systems, its inherent brittleness makes it vulnerable to the tensile stresses of internal pressure. A thorough engineering analysis of your specific application is not just recommended—it is essential for safety and reliability.

Why Alumina is Considered for Extreme Environments

High-purity alumina (Al₂O₃) is a go-to material for demanding furnace applications because of a unique combination of properties that allow it to maintain integrity when other materials would fail.

Exceptional Thermal Stability

Alumina ceramics possess a very high melting point and retain their structural integrity at extreme temperatures. This makes them ideal for processes running well over 1500°C in inert, reducing, or high-vacuum atmospheres.

High Chemical Inertness

This material exhibits remarkable resistance to chemical attack and erosion. It remains stable when exposed to a wide range of corrosive substances, ensuring process purity and extending the life of the furnace components.

Superior Mechanical Hardness

Alumina is an extremely hard material, which translates to excellent resistance to wear and abrasion. This property is critical in applications where physical contact or particulate flow is expected.

The Critical Factor: Compressive vs. Tensile Strength

The decision to use an alumina tube for a pressure application hinges on understanding how ceramics behave under different types of stress. This is the single most important factor to consider.

Alumina's Strength in Compression

Ceramics are exceptionally strong when squeezed or compressed. This is why an alumina tube is an outstanding choice for high-vacuum furnaces or systems with high external pressure, where the forces are pushing inward on the tube.

The Challenge of Tensile Stress

The primary weakness of alumina is its brittleness and low tensile strength. When a tube is pressurized from the inside, its walls are subjected to "hoop stress," a tensile force pulling them apart. This is where alumina is most likely to fail.

The Role of Wall Thickness and Geometry

To mitigate the risk of failure under internal pressure, a thicker tube wall can be used. However, this is a matter of careful engineering calculation. The tube's diameter, length, and the magnitude of the pressure must all be factored into a formal stress analysis.

Understanding the Trade-offs

While powerful, alumina is not a universally perfect solution. Being aware of its limitations is crucial for safe and effective system design.

Brittleness and Catastrophic Failure

Unlike metals, which will bend or deform plastically before breaking, ceramics fail catastrophically. An over-pressurized alumina tube will not stretch; it will shatter. This risk must be managed with precise pressure controls and safety relief systems.

Purity and Manufacturing Defects

The mechanical strength of a ceramic tube is heavily dependent on its purity and the absence of microscopic flaws. Voids or micro-cracks from the manufacturing process can act as stress concentrators, becoming the origin point for a catastrophic failure under pressure. Always source from a reputable supplier with clear specifications.

Alternatives: Quartz and Metal Alloys

For some high-pressure applications, other materials may be more suitable. High-purity quartz tubes offer excellent thermal properties and can be a good choice for moderate pressures. For very high internal pressures, especially when combined with thermal cycling, specialized metal alloy tubes (e.g., Inconel, molybdenum) are often the safer and more reliable choice.

Making the Right Choice for Your Goal

To determine if alumina is the correct material, evaluate your primary operational need.

- If your primary focus is extreme temperature and chemical resistance under external pressure or in a vacuum: High-purity alumina is an excellent choice due to its superior compressive strength.

- If your application involves significant internal pressure: You must perform a rigorous stress analysis, and often metal alloys or specially engineered, thick-walled ceramics are safer alternatives.

- If you need high purity with moderate pressure and excellent thermal shock resistance: High-purity quartz can be a viable alternative to consider alongside alumina.

Ultimately, matching the material's fundamental properties to the specific stress profile of your system is the key to safe and reliable operation.

Summary Table:

| Factor | Suitability for High-Pressure Applications |

|---|---|

| Compressive Strength | Excellent for external pressure or vacuum systems |

| Tensile Strength | Poor for internal pressure; risk of brittle failure |

| Thermal Stability | High, suitable for temperatures over 1500°C |

| Chemical Inertness | Excellent, resists corrosion and maintains purity |

| Wall Thickness | Critical; thicker walls can mitigate internal pressure risks |

| Alternatives | Quartz for moderate pressure, metal alloys for high internal pressure |

Need a reliable furnace solution for your high-pressure or high-temperature applications? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet the unique experimental requirements of diverse laboratories. Contact us today to enhance your lab's safety and efficiency with tailored furnace systems!

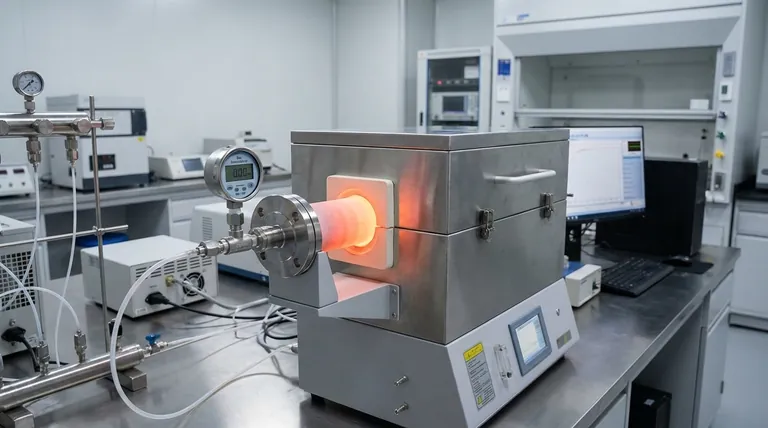

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide