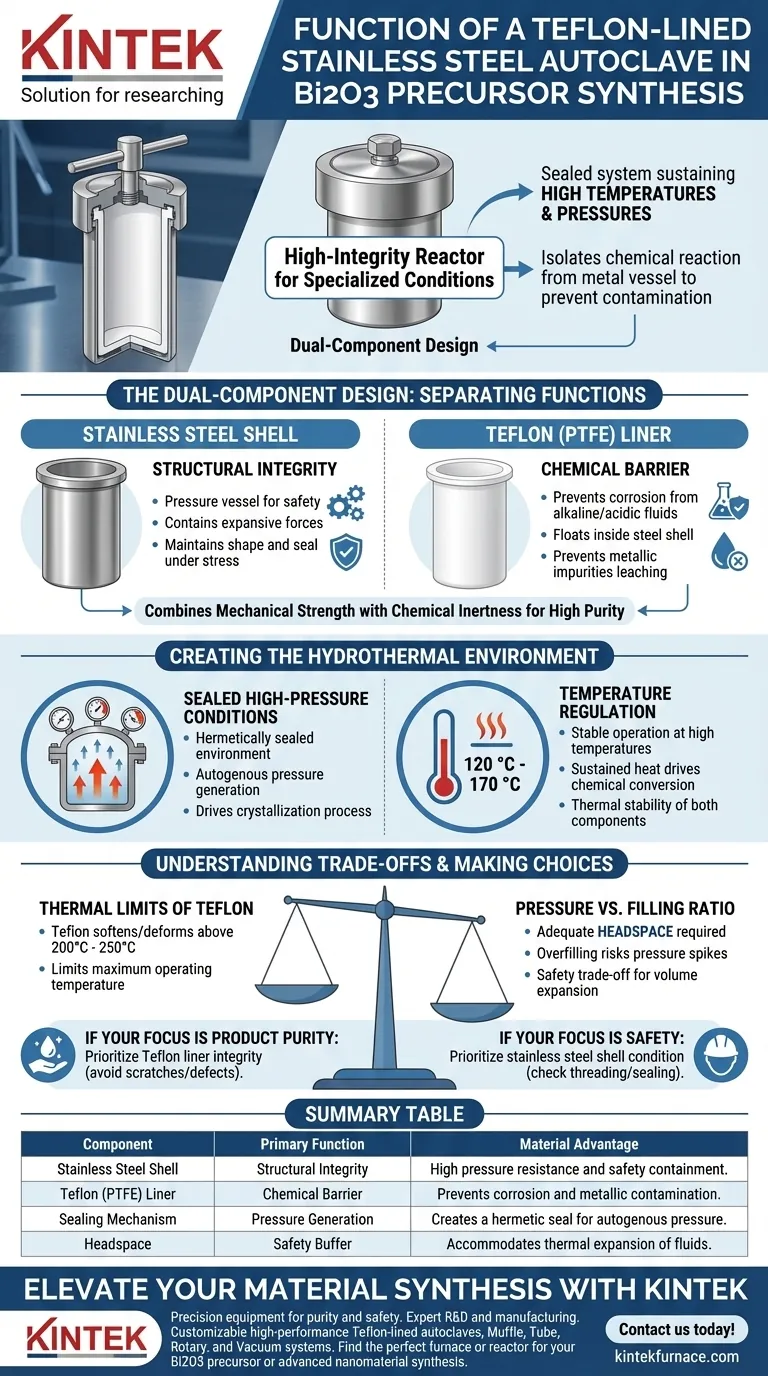

A Teflon-lined stainless steel autoclave serves as a specialized, high-integrity reactor used to generate the specific environmental conditions required for synthesizing Bi2O3 precursors. Its primary function is to create a sealed system that sustains high temperatures and pressures while completely isolating the chemical reaction from the metal vessel to prevent contamination.

By combining the mechanical strength of steel with the chemical inertness of Teflon, this device allows for hydrothermal crystallization under extreme conditions without compromising the purity of the final Bi2O3 product.

The Dual-Component Design

The efficacy of this autoclave lies in the separation of its structural and chemical functions. This hybrid design addresses two distinct challenges in hydrothermal synthesis.

The Role of the Stainless Steel Shell

The outer shell provides the structural integrity required for safety. Hydrothermal reactions often generate significant internal pressure that would rupture weaker materials.

The stainless steel functions as a pressure vessel, containing the expansive forces generated by the heated solvents. It ensures the reactor maintains its shape and seal, regardless of the internal stress.

The Role of the Teflon Liner

The inner Teflon (PTFE) liner acts as a chemical barrier. Because the synthesis of Bi2O3 precursors often involves highly alkaline or acidic fluids, direct contact with metal would cause corrosion.

This liner effectively "floats" inside the steel shell, holding the reactants. It ensures that the reaction fluids never touch the steel walls, preventing metallic impurities from leaching into and ruining the reaction product.

Creating the Hydrothermal Environment

Beyond containment, the autoclave actively generates the conditions necessary for precursor formation.

Sealed High-Pressure Conditions

The autoclave provides a hermetically sealed environment. As the temperature rises, the liquid solvents inside cannot escape, leading to the generation of autogenous (self-generated) pressure.

This pressure forces the reactants to interact in ways that are impossible under standard atmospheric conditions. It drives the crystallization process, allowing the Bi2O3 precursors to form specific structures.

Temperature Regulation

The device allows for stable operation at high temperatures, typically ranging from 120 °C to 170 °C depending on the specific synthesis protocol.

The thermal stability of both the steel and the Teflon allows the system to hold these temperatures for extended periods. This sustained heat provides the energy required to drive the chemical conversion of raw materials into the desired precursor lattice.

Understanding the Trade-offs

While this equipment is the standard for high-purity synthesis, it is important to understand its operational limits.

Thermal Limits of Teflon

While the stainless steel shell can withstand extreme heat, the Teflon liner is the limiting factor. Teflon begins to soften or deform at very high temperatures (typically above 200°C - 250°C), which restricts the maximum operating temperature of the synthesis compared to unlined metal reactors.

Pressure vs. Filling Ratio

The sealed nature of the vessel creates a safety trade-off regarding volume expansion. You cannot fill the liner completely; adequate headspace is required to accommodate the expansion of gases and liquids. Overfilling can lead to dangerous pressure spikes that test the limits of the stainless steel shell.

Making the Right Choice for Your Goal

When setting up your synthesis of Bi2O3 precursors, understanding the function of each component helps you optimize your results.

- If your primary focus is Product Purity: Prioritize the integrity of the Teflon liner. Any scratches or defects in the liner will expose the reactants to the steel, introducing impurities like iron or chromium into your Bi2O3.

- If your primary focus is Safety: Prioritize the condition of the stainless steel shell. Ensure the threading and sealing mechanisms are intact to handle the autogenous pressure generated at your target temperature.

The Teflon-lined autoclave is the definitive tool for this process because it uniquely balances the need for extreme physical conditions with the need for delicate chemical purity.

Summary Table:

| Component | Primary Function | Material Advantage |

|---|---|---|

| Stainless Steel Shell | Structural Integrity | High pressure resistance and safety containment. |

| Teflon (PTFE) Liner | Chemical Barrier | Prevents corrosion and metallic contamination. |

| Sealing Mechanism | Pressure Generation | Creates a hermetic seal for autogenous pressure. |

| Headspace | Safety Buffer | Accommodates thermal expansion of fluids. |

Elevate Your Material Synthesis with KINTEK

Precision in hydrothermal synthesis requires equipment that never compromises on purity or safety. Backed by expert R&D and manufacturing, KINTEK offers high-performance Teflon-lined autoclaves, Muffle, Tube, Rotary, and Vacuum systems, all fully customizable to meet your laboratory's unique high-temp needs.

Whether you are synthesizing Bi2O3 precursors or advanced nanomaterials, our specialized high-temperature solutions provide the thermal stability and chemical resistance your research demands.

Ready to optimize your lab's performance? Contact us today to find the perfect furnace or reactor for your application!

Visual Guide

References

- Fan Yang, Wanfeng Xie. Structural design of highly permeable Bi <sub>2</sub> O <sub>3</sub> microspheres decorated by Pt‐nanoparticles: facile synthesis and acetic acid sensing performance. DOI: 10.1007/s12598-025-03391-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What is the function of graphite molds in the Spark Plasma Sintering (SPS) of high-entropy alloys?

- What are the key characteristics of the alumina furnace tube? Essential for High-Temp Lab Success

- What are the advantages of using a laboratory vacuum drying oven for modified ZnO nanomaterials? Protect Nano-Integrity

- What is the function of high-purity alumina crucibles? Achieve Precise Results in Pyroprocessing Salt Research

- Why is a mass flow controller essential in the tracer method? Precision Data for Pyrolysis Gas Flow

- Why are alumina crucibles used for CoNb2O6 synthesis? Ensure High-Purity Ceramic Powder Production

- What is the function of a vacuum system in PLD? Ensure High-Density, Pure Electrolyte Thin Films

- What are the key advantages of using quartz tubes in high-temperature applications? Achieve Unmatched Thermal Stability and Purity