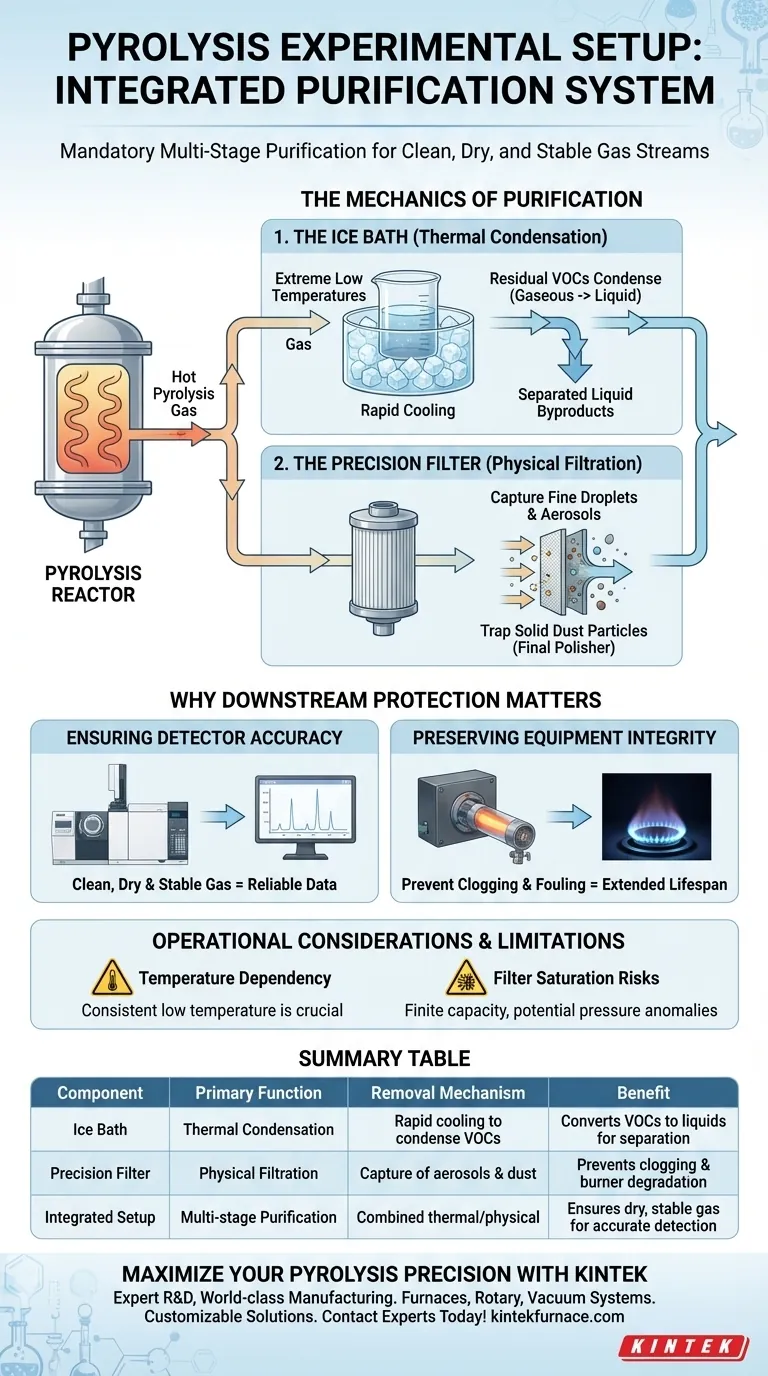

Precision filters and ice baths function as a mandatory multi-stage purification system within pyrolysis experimental setups. They are integrated to systematically strip the generated gas of impurities before it reaches sensitive downstream components. By combining thermal condensation with physical filtration, this configuration ensures the gas stream is clean, dry, and chemically stable.

By layering the thermal condensation capabilities of an ice bath with the physical capture of a precision filter, this system eliminates volatile organic compounds and particulates that would otherwise corrupt data or damage equipment.

The Mechanics of Purification

To understand the necessity of these components, one must look at how they manage the chaotic byproducts of pyrolysis.

The Role of the Ice Bath

The ice bath serves as the first line of defense, utilizing extremely low temperatures to alter the physical state of the gas components.

By rapidly cooling the gas stream, the ice bath physically forces residual volatile organic compounds (VOCs) to condense.

This process effectively transitions these unwanted compounds from a gaseous state into a liquid state, separating them from the carrier gas.

The Function of the Precision Filter

Once the gas has passed through the thermal treatment of the ice bath, it enters the precision filter.

This component is designed to capture any fine droplets that escaped condensation or aerosols formed during cooling.

Additionally, the filter traps solid dust particles generated during the pyrolysis process, acting as a final polisher for the gas stream.

Why Downstream Protection Matters

The ultimate goal of this integration is not just separation, but the protection of the analytical instruments that follow.

Ensuring Detector Accuracy

Detectors and burners require a specific gas composition to function correctly.

If the gas contains moisture or organic residues, the resulting measurements will be unstable and inaccurate.

This system guarantees the gas entering these devices is dry and stable, providing a reliable baseline for data collection.

Preserving Equipment Integrity

Pyrolysis gases are often "dirty," laden with tars and particulates that can foul delicate equipment.

Without the precision filter removing fine dust, burners can clog and sensors can degrade rapidly.

The purification system extends the operational lifespan of the entire experimental rig.

Operational Considerations and Limitations

While this system is highly effective, it introduces specific dependencies that must be managed to maintain performance.

The Dependency on Temperature

The efficiency of the entire setup relies heavily on the ice bath maintaining a consistently low temperature.

If the temperature fluctuates or rises, VOCs will not condense effectively, bypassing the first stage and potentially overwhelming the filter.

Filter Saturation Risks

The precision filter acts as a physical barrier, which means it has a finite capacity.

If the ice bath fails to remove the bulk of the liquids, the filter can become saturated with droplets quickly.

This saturation restricts gas flow and can lead to pressure anomalies that skew experimental results.

Making the Right Choice for Your Goal

To maximize the effectiveness of your pyrolysis setup, you must align the maintenance of these components with your specific experimental objectives.

- If your primary focus is Data Accuracy: Monitor the ice bath temperature rigorously to ensure total condensation of volatile compounds before they reach the detector.

- If your primary focus is Equipment Longevity: Prioritize the regular replacement of precision filters to prevent dust accumulation from clogging burners.

This integrated approach is the only way to transform raw pyrolysis emissions into a reliable, measurable gas stream.

Summary Table:

| Component | Primary Function | Removal Mechanism | Benefit to System |

|---|---|---|---|

| Ice Bath | Thermal Condensation | Rapid cooling of gas stream | Converts VOCs to liquids for separation |

| Precision Filter | Physical Filtration | Capture of aerosols & dust | Prevents clogging and burner degradation |

| Integrated Setup | Multi-stage Purification | Combined thermal/physical | Ensures dry, stable gas for accurate detection |

Maximize Your Pyrolysis Precision with KINTEK

Don’t let impurities compromise your research data or damage your high-value equipment. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of lab solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard configurations or fully customizable high-temp furnaces tailored to your unique experimental needs, we provide the stability and precision your lab demands.

Ready to upgrade your thermal processing setup? Contact KINTEK experts today to find your perfect solution!

Visual Guide

References

- Zsolt Dobó, Gábor Nagy. Production of Biochar by Pyrolysis of Food Waste Blends for Negative Carbon Dioxide Emission. DOI: 10.3390/en18010144

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of using a platinum crucible? Essential for High-Purity Alumino-Borosilicate Glass Synthesis

- What role do refractory bricks and graphite paper play within a quartz tube? Optimize RuMoOx/NC Synthesis Efficiency

- What is the role of a Teflon-lined autoclave in CeO2 synthesis? Achieve Pure, Monodisperse Nanomaterials

- Why is it necessary to use a mechanical vacuum pump for SnSe growth? Ensure High-Purity Material Synthesis

- What technical foundations support the development of laboratory high-temperature furnace systems? Expert R&D & Mfg

- What maintenance is required after using the alumina furnace tube? Ensure Longevity and Purity in Your Lab

- Why are alumina crucibles used for CoNb2O6 synthesis? Ensure High-Purity Ceramic Powder Production

- Why is a laboratory vacuum degasser necessary for biochar? Ensure Accurate BET Structural Characterization