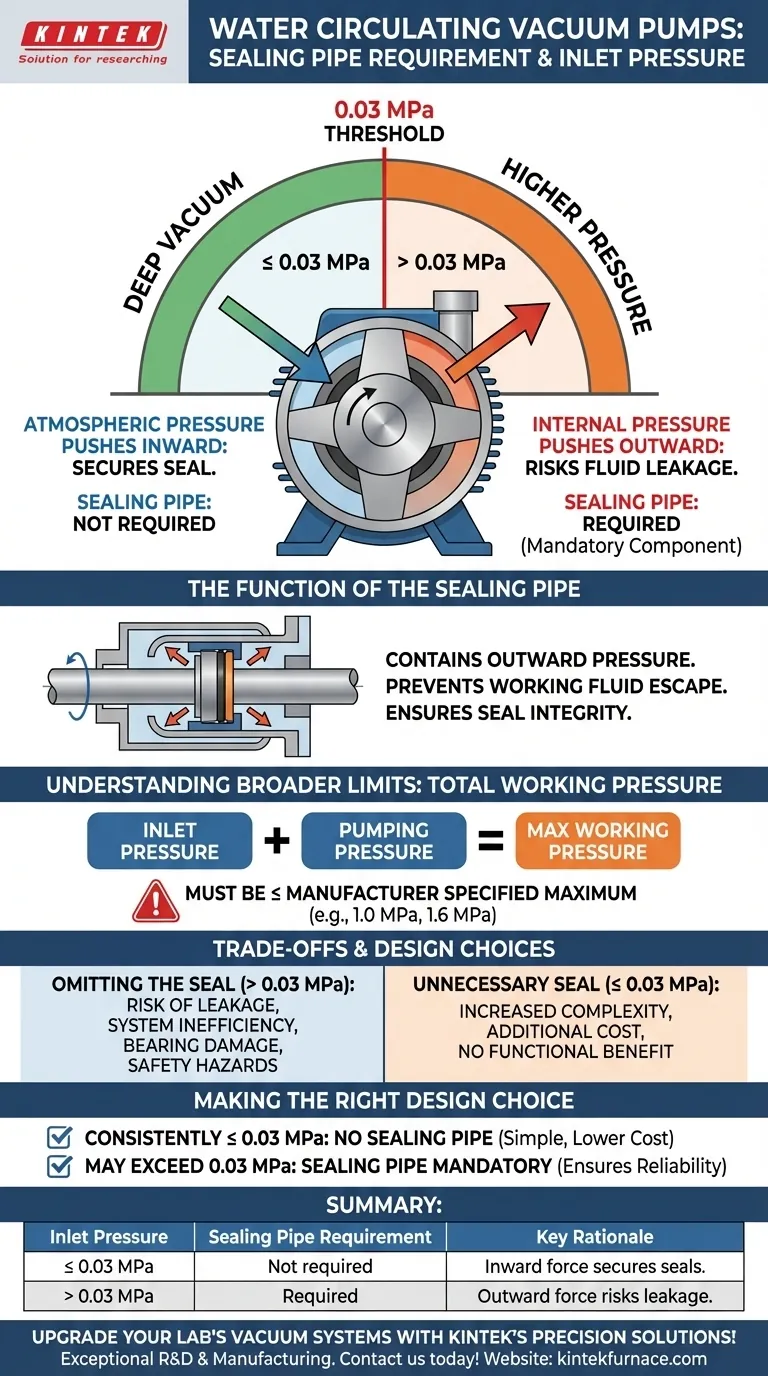

The critical threshold for a sealing pipe in a water circulating vacuum pump is determined by its inlet pressure. Based on standard engineering design, if the inlet pressure remains at or below 0.03 Megapascals (MPa), a dedicated sealing pipe structure is not required. Above this value, it becomes a necessary component to ensure system integrity.

The need for a sealing pipe is fundamentally about managing pressure differentials. When a pump operates in a deep vacuum, external atmospheric pressure helps secure the seals. As inlet pressure rises, this dynamic reverses, creating a risk of internal fluid leakage that a sealing pipe is designed to prevent.

The Core Principle: Sealing Against Pressure

To properly apply the 0.03 MPa rule, you must first understand the physics at play around the pump's shaft seals. The decision is not arbitrary; it is based on the direction of the net pressure force.

When Operating in a Deep Vacuum (≤ 0.03 MPa)

When the inlet pressure is extremely low, the inside of the pump is at a lower pressure than the outside atmosphere.

This pressure differential creates a net force that pushes inward on the shaft seals. This external atmospheric pressure effectively helps secure the seal, preventing air from leaking into the pump and working fluid from leaking out.

When Inlet Pressure Rises (> 0.03 MPa)

As the inlet pressure increases, the internal pressure of the pump can approach or exceed the external atmospheric pressure.

This condition reverses the pressure differential. The net force now pushes outward on the shaft seals, creating a significant risk that the internal working fluid (water) will be forced out along the shaft.

The Function of the Sealing Pipe

The sealing pipe and its associated parts are a structural solution to this outward pressure problem.

This assembly is designed to contain the internal pressure and prevent the working fluid from escaping. It ensures the seal remains effective even when the pump's internal pressure is higher than the atmosphere.

Understanding the Broader Operational Limits

The 0.03 MPa threshold for the sealing pipe is only one part of the system's pressure specifications. You must also consider the pump's total capacity to ensure safe operation.

Inlet Pressure vs. Total Working Pressure

The sealing pipe requirement is an initial design consideration based on inlet conditions. However, the overall structural integrity of the pump is determined by the maximum working pressure.

This is calculated as the sum of the inlet pressure and the pumping pressure generated by the pump itself.

Manufacturer-Specified Maximums

Pump manufacturers provide clear limits for maximum working pressure. For example, a standard pump might be rated for 1.0 MPa, while higher-capacity models (often defined by head, or Hsp) might be rated for 1.6 MPa or even 2.5 MPa with special configurations.

Exceeding this total pressure can lead to catastrophic failure, regardless of whether a sealing pipe is correctly installed.

Understanding the Trade-offs

Making the correct choice has direct implications for cost, complexity, and reliability.

The Risk of Omitting the Seal

If your inlet pressure exceeds 0.03 MPa and you do not install a sealing pipe, the primary risk is leakage of the working fluid.

This can lead to a loss of system efficiency, damage to the pump's bearings from fluid contamination, and potential safety hazards in the surrounding area.

The Cost of an Unnecessary Seal

If your system will only ever operate in a deep vacuum (≤ 0.03 MPa), installing a sealing pipe adds unnecessary complexity and cost.

It introduces additional components that require installation and potential maintenance without providing any functional benefit under these specific operating conditions.

Making the Right Design Choice

Use these guidelines to determine the correct specification for your application.

- If your system consistently operates with an inlet pressure below 0.03 MPa: You can design the system without a dedicated sealing pipe structure, simplifying installation and reducing cost.

- If your system's inlet pressure may exceed 0.03 MPa at any point: A sealing pipe installation is a mandatory design requirement to ensure seal integrity and prevent fluid leakage.

- Regardless of the sealing pipe decision: You must always ensure the calculated maximum working pressure (inlet + pumping) remains safely within the manufacturer's specified limits for your pump.

By correctly applying this pressure threshold, you ensure the long-term reliability and integrity of your vacuum pump system.

Summary Table:

| Inlet Pressure | Sealing Pipe Requirement | Key Rationale |

|---|---|---|

| ≤ 0.03 MPa | Not required | Inward pressure force from atmosphere secures seals, preventing leaks |

| > 0.03 MPa | Required | Outward pressure force risks fluid leakage, necessitating sealing pipe |

Upgrade your lab's vacuum systems with KINTEK's precision solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, tailored to your unique needs. Our deep customization ensures optimal performance for diverse laboratory applications. Contact us today to discuss how we can enhance your experimental reliability and efficiency!

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- What is the function of graphite molds in the Spark Plasma Sintering (SPS) of high-entropy alloys?

- What type of medium is allowed in water circulating vacuum pumps? Ensure Optimal Performance and Longevity

- How does a sealed high-purity graphite reaction box function? Optimize Sb-Ge Thin Film Selenization

- What is the function of BN coating in Y2O3-YAM hot-press sintering? Ensure Purity and Smooth Mold Release

- What is the importance of a water-cooled injector in DTF experiments? Ensure Precise Ignition Delay Measurement

- How does an infrared (IR) pyrometer improve thermal control? Direct Precision for MBE Growth and Annealing

- How does the circulating water vacuum pump work? Uncover the Liquid Piston Mechanism

- Why is a high-vacuum system required for sealing quartz tubes? Achieve Ultra-Pure Chalcogenide Alloy Synthesis