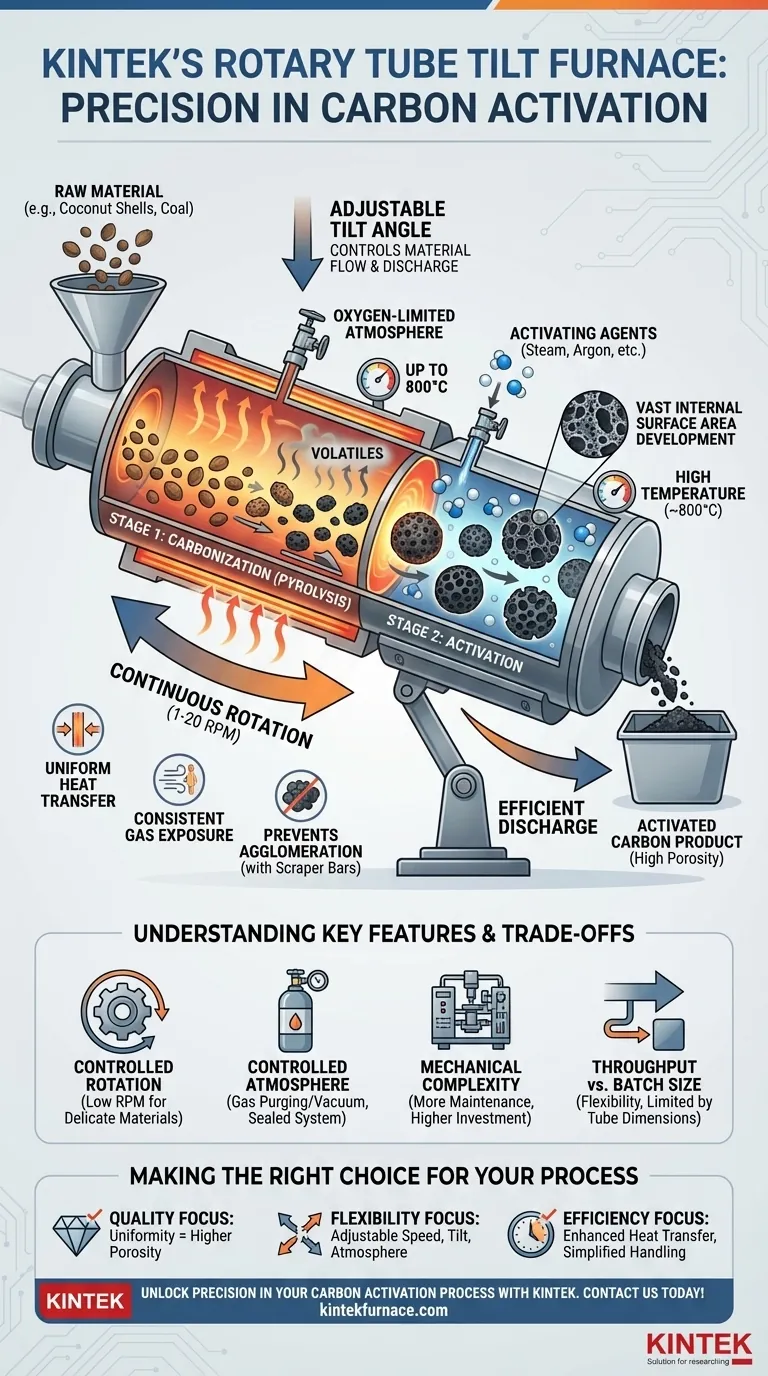

In essence, a Rotary Tube Tilt Furnace is used in carbon activation to precisely control the heat treatment and atmospheric exposure of raw carbon materials. Its unique combination of continuous rotation and adjustable tilt ensures every particle is uniformly processed, transforming materials like coconut shells or coal into high-porosity activated carbon with a vast internal surface area.

The core value of this furnace is not just heating, but creating a dynamic, controlled environment. Its ability to rotate and tilt ensures unparalleled uniformity in the activation process, which is the critical factor for producing high-performance activated carbon.

The Core Principle: Why Rotation and Tilt Matter

A static furnace heats material in a fixed position, often leading to hot spots and uneven processing. A Rotary Tube Tilt Furnace solves this fundamental problem through controlled movement.

Uniform Heat Transfer

The slow, continuous rotation of the furnace tube ensures that the material inside is constantly tumbling. This movement exposes all sides of every particle to the heat source, eliminating inconsistencies and guaranteeing uniform carbonization and activation.

Consistent Exposure to Activating Agents

The activation stage requires exposing the carbonized material to specific gases, such as steam or argon, at high temperatures. The furnace's rotation ensures every particle is consistently bathed in these activating agents, which is essential for developing a homogenous network of pores.

Preventing Agglomeration

Particulate materials, especially at high temperatures, can stick together or agglomerate. The constant tumbling motion, often aided by internal scraper bars, breaks up potential clumps, ensuring the material remains free-flowing and is processed as individual particles.

A Look at the Activation Process Inside the Furnace

The transformation from raw material to activated carbon occurs in distinct stages within the furnace's controlled environment.

Stage 1: Carbonization

First, the raw carbonaceous material is heated in an oxygen-limited environment to drive off volatile compounds. This process, known as carbonization or pyrolysis, leaves behind a fixed-carbon char with a rudimentary pore structure.

Stage 2: Activation

The furnace temperature is then raised, typically up to 800°C for this process, and an activating agent is introduced into the sealed tube. This agent etches away at the internal structure of the carbon char, vastly increasing the number of pores and expanding the surface area.

Material Handling and Discharge

The tilt angle of the furnace is critical for controlling material flow. A steeper angle results in a faster throughput for continuous operation. When the process is complete, tilting the furnace facilitates a simple, efficient discharge of the finished activated carbon.

Understanding the Trade-offs and Key Features

While highly effective, this furnace's design comes with specific characteristics that define its ideal use cases. Its advantages are rooted in a set of key mechanical features.

Controlled Rotation Speed

These furnaces operate at a very low RPM (1-20 RPM). This gentle tumbling is ideal for delicate materials, ensuring thorough mixing without causing mechanical degradation or turning the product into dust.

Controlled Atmosphere

The ability to seal the tube and purge it with specific gases (gas purging) or operate under a vacuum is fundamental. This provides the flexibility to create the precise oxygen-free or agent-rich atmosphere required for both carbonization and activation.

Mechanical Complexity

The primary trade-off is increased mechanical complexity compared to a static batch furnace. The rotating seals, drive motor, and tilting mechanism require more maintenance and represent a higher initial investment. However, this complexity is what enables superior product quality and process control.

Throughput vs. Batch Size

The furnace's ability to run in both batch and continuous modes offers flexibility. However, the diameter and length of the tube will inherently limit the maximum batch size or continuous throughput rate. This must be matched to production requirements.

Making the Right Choice for Your Process

Selecting this technology depends entirely on your primary process goals.

- If your primary focus is final product quality: This furnace is the superior choice, as its uniform heat and gas exposure directly lead to higher and more consistent porosity and surface area.

- If your primary focus is process flexibility: The ability to control rotation speed, tilt angle, atmosphere, and operate in both batch or continuous modes makes it adaptable to various materials and research goals.

- If your primary focus is operational efficiency: The enhanced heat transfer improves energy efficiency, and the tilting function simplifies material handling, reducing labor and time between batches.

Ultimately, this furnace provides the precise, dynamic control necessary to engineer activated carbon with specific, high-performance characteristics for demanding applications.

Summary Table:

| Feature | Role in Carbon Activation |

|---|---|

| Rotation | Ensures uniform heat transfer and prevents agglomeration for consistent particle processing |

| Tilt | Controls material flow and discharge, enabling batch or continuous operation |

| Controlled Atmosphere | Allows precise gas exposure (e.g., steam, argon) for effective activation and pore development |

| Temperature Control | Maintains high temperatures (up to 800°C) for carbonization and activation stages |

| Low RPM Operation | Gentle tumbling (1-20 RPM) protects delicate materials from degradation |

Unlock Precision in Your Carbon Activation Process with KINTEK

Are you aiming for superior activated carbon with high porosity and uniform quality? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our Rotary Tube Tilt Furnaces, part of a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, offer deep customization to meet unique experimental requirements. Whether you're in research or production, our furnaces ensure consistent results and enhanced efficiency. Contact us today to discuss how we can optimize your carbon activation process and deliver reliable, high-performance solutions!

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What makes rotary tube furnaces user-friendly? Achieve Superior Process Uniformity and Efficiency

- What level of process control do rotary tube furnaces provide? Achieve Precise Thermal Processing for Uniform Results

- What is the role of rotary tube furnaces in the energy sector? Boost Efficiency in Biomass and Battery Material Processing

- How do rotary tube furnaces enhance efficiency in materials processing? Boost Throughput and Quality

- In what environments are rotary tube furnaces considered indispensable? Essential for Uniform Thermal Processing