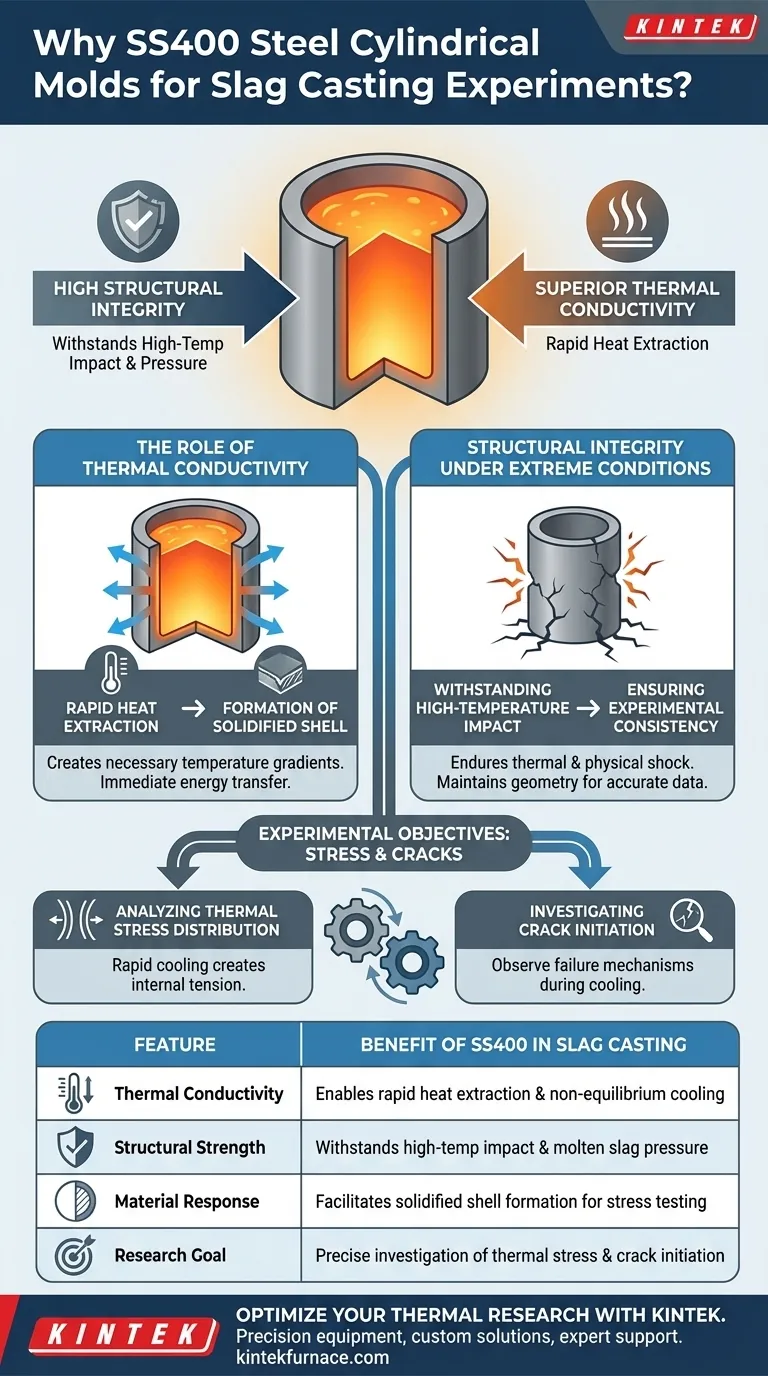

The selection of an SS400 steel cylindrical mold is dictated by the requirement for high structural integrity and specific thermal behavior. Researchers utilize this industrial-grade material because it can withstand the physical impact of molten slag while simultaneously driving the thermodynamics required for the experiment. Its superior thermal conductivity is the primary mechanism that enables the study of complex solidification phenomena.

Core Takeaway The SS400 mold serves a dual purpose: it acts as a robust container capable of surviving high-temperature impact and as a thermal conductor that forces rapid cooling. This precise environmental control is necessary to create the solidified shell required to investigate thermal stress and crack initiation.

The Role of Thermal Conductivity

Rapid Heat Extraction

The defining characteristic of the SS400 mold in this context is its superior thermal conductivity. It functions not just as a vessel, but as an active component in the thermal lifecycle of the slag.

Upon contact, the mold rapidly extracts heat from the surface of the molten slag. This immediate energy transfer is critical for establishing the temperature gradients necessary for the experiment.

Formation of the Solidified Shell

The rapid cooling facilitates the immediate formation of a solidified shell. This is not an accidental byproduct but a targeted experimental outcome.

This shell possesses specific mechanical strength characteristics. The creation of this solid boundary layer is the prerequisite for analyzing how the material behaves as it transitions from liquid to solid.

Structural Integrity Under Extreme Conditions

Withstanding High-Temperature Impact

Casting molten slag involves extreme thermal and physical shock. The mold must possess high structural strength to endure the initial impact of the pour without deforming or failing.

SS400 steel provides the industrial-grade durability required to maintain the geometry of the cylinder throughout the casting process.

Ensuring Experimental Consistency

By resisting deformation under heat and load, the mold ensures that the physical dimensions of the experiment remain constant. This stability is vital for accurate data collection regarding stress distribution.

Experimental Objectives: Stress and Cracks

Analyzing Thermal Stress Distribution

The ultimate goal of using this specific setup is to study thermal stress distribution. The rapid cooling provided by the SS400 mold creates the internal tensions researchers need to measure.

Investigating Crack Initiation

The experiment is designed to identify mechanisms of crack initiation. By forcing the formation of a solidified shell through rapid heat extraction, researchers can observe exactly when and why the material fails during the cooling phase.

Understanding the Experimental Dynamics

The Necessity of Rapid Cooling

It is important to recognize that this setup is specifically tuned for non-equilibrium cooling. The use of SS400 is intended to induce thermal stress, not to avoid it.

Material Specificity

The success of this experiment relies on the specific pairing of the mold's conductivity with the slag's thermal properties. Using a mold with lower conductivity would likely result in slower cooling, potentially failing to generate the specific shell structure or crack mechanisms being studied.

Making the Right Choice for Your Goal

The selection of mold material is never arbitrary; it dictates the thermal history of your casting.

- If your primary focus is studying failure mechanisms: Choose a material with high thermal conductivity (like SS400) to induce rapid cooling and force the initiation of cracks for analysis.

- If your primary focus is process safety: Prioritize industrial-grade structural strength to ensure the mold can withstand the kinetic energy and thermal shock of the molten pour.

By leveraging the conductive and structural properties of SS400, you transform a simple casting container into a precision instrument for analyzing thermal stress.

Summary Table:

| Feature | Benefit of SS400 in Slag Casting |

|---|---|

| Thermal Conductivity | Enables rapid heat extraction and non-equilibrium cooling |

| Structural Strength | Withstands high-temperature impact and molten slag pressure |

| Material Response | Facilitates the formation of a solidified shell for stress testing |

| Research Goal | Allows precise investigation of thermal stress and crack initiation |

Optimize Your Thermal Research with KINTEK

Precision in slag casting and materials analysis starts with the right equipment. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other laboratory high-temperature furnaces.

Whether you require specialized SS400 molds or custom-engineered heating solutions, our equipment is fully customizable to meet your unique experimental needs. Achieve superior consistency and durability in your lab—contact KINTEK today to consult with our technical specialists!

Visual Guide

Related Products

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the purpose of using a high-purity ceramic crucible with a sealed lid during the thermal treatment of biochar?

- How does the circulating water vacuum pump work? Uncover the Liquid Piston Mechanism

- Why are laboratory furnaces considered essential in industrial and scientific applications? Unlock Precision and Control for Your Materials

- How is measurement accuracy maintained for infrared pyrometers? Master Optical Hygiene for High-Temp Metallic Melts

- How does Energy Dispersive X-ray Spectroscopy (EDX) assist in adjusting furnace parameters? Biochar Quality Control

- How are quartz tubes used in laboratory applications? Essential for High-Temp, High-Purity Processes

- What is the significance of using a laboratory electric thermostatic blast drying oven for biomass briquette moisture control?

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure