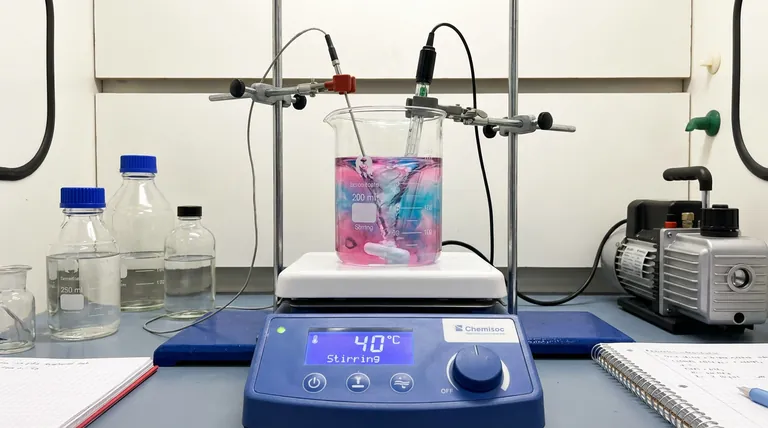

The magnetic stirring hot plate functions as the central control unit for reaction kinetics and homogeneity. In the chemical precipitation synthesis of cobalt oxide nanoparticles, this device simultaneously maintains a specific thermal environment (typically 40°C) while providing continuous mechanical agitation. Its primary technical role is to facilitate thorough contact between the cobalt nitrate precursor and the ammonia solution, ensuring the reaction occurs uniformly throughout the entire volume of the solution.

By synchronizing thermal energy with mechanical dispersion, the device allows precise control over particle nucleation. This consistency is the defining factor in achieving the correct stoichiometry and preventing irregular particle growth.

The Role of Mechanical Agitation

Ensuring Uniform Precursor Contact

The synthesis process relies on the reaction between cobalt nitrate and an ammonia precipitant. Without constant agitation, these chemicals would mix unevenly, creating localized "hotspots" of high concentration.

Continuous magnetic stirring forces the reactants to disperse immediately upon contact. This ensures that the chemical potential is equalized across the beaker, allowing the precipitation reaction to start simultaneously everywhere in the solution.

Controlling the Nucleation Process

The speed and consistency of stirring directly dictate the nucleation phase—the moment nanoparticles begin to form.

If the stirring is inconsistent, nucleation occurs sporadically, leading to particles of varying sizes. Steady mechanical stirring standardizes this process, which is essential for synthesizing nanoparticles with a narrow size distribution and controlled morphology.

The Role of Thermal Regulation

Driving Reaction Kinetics

Temperature is the energy source that drives the chemical conversion. The hot plate maintains a constant temperature, such as 40°C, which is specific to the optimal formation of cobalt oxide precursors.

This thermal energy overcomes the activation barrier required for the reaction to proceed. Maintaining a fixed temperature prevents the reaction from stalling (if too cold) or proceeding too aggressively (if too hot), which preserves the structural integrity of the particles.

Securing Consistent Stoichiometry

Stoichiometry refers to the precise ratio of elements in the final chemical structure. Fluctuations in temperature can alter how the cobalt and oxygen atoms bond.

By providing a stable thermal baseline, the hot plate ensures that the chemical composition of the final cobalt oxide product remains consistent batch-to-batch. This stability is vital for ensuring the material exhibits the expected magnetic and electronic properties.

Common Pitfalls to Avoid

The Risk of Thermal Gradients

A common oversight is assuming the temperature is uniform simply because the plate is set to 40°C. Without adequate stirring, the solution near the bottom of the beaker will be hotter than the surface.

This thermal gradient can cause uneven reaction rates within the same vessel. High-intensity stirring is required not just for mixing chemicals, but for distributing heat evenly to eliminate these gradients.

Variable Stirring Speeds

Inconsistent rotation speeds can lead to "dead zones" in the reaction vessel where mixing is poor.

If the magnetic bar decouples or creates a vortex that is too deep, the effectiveness of the dispersion drops. It is critical to find a stirring speed that maximizes turbulence without introducing air bubbles or splashing the solution.

Making the Right Choice for Your Goal

To optimize your synthesis of cobalt oxide nanoparticles, align your equipment settings with your specific objectives:

- If your primary focus is Particle Size Uniformity: Prioritize high, consistent stirring speeds to ensure rapid dispersion and simultaneous nucleation across the entire solution volume.

- If your primary focus is Chemical Purity (Stoichiometry): Focus on precise thermal regulation to maintain the reaction at exactly 40°C, preventing secondary phases or incomplete reactions.

Success in chemical precipitation lies in the rigorous control of reaction variables, transforming chaotic chemical potential into ordered nanostructures.

Summary Table:

| Technical Function | Role in Synthesis | Impact on Final Product |

|---|---|---|

| Mechanical Agitation | Ensures uniform precursor contact & prevents hotspots | Narrow particle size distribution & morphology |

| Thermal Regulation | Provides activation energy & drives reaction kinetics | Consistent stoichiometry & chemical purity |

| Homogenization | Eliminates thermal gradients & concentration dead zones | Batch-to-batch repeatability & structural integrity |

| Kinetic Control | Manages the rate of nucleation vs. particle growth | Optimized magnetic and electronic properties |

Elevate Your Material Synthesis with KINTEK Precision

Achieving the perfect nanostructure requires more than just chemistry—it requires rigorous control over thermal and mechanical variables. Backed by expert R&D and manufacturing, KINTEK offers a wide range of laboratory equipment including high-performance magnetic stirring hot plates and advanced furnace systems like Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique research needs.

Ready to achieve superior particle uniformity and chemical purity? Contact us today to find the perfect solution for your lab!

Visual Guide

References

- Ali Dehbi, Adil Lamini. A Statistical Physics Approach to Understanding the Adsorption of Methylene Blue onto Cobalt Oxide Nanoparticles. DOI: 10.3390/molecules29020412

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

People Also Ask

- What are the benefits of sealing SAC305 solder in vacuum quartz tubes? Ensure High-Reliability Alloy Integrity

- What is the significance of quartz vacuum sealing technology in Dy4T1-xGa12 production? Ensure High-Purity Synthesis

- What are the advantages of using high-purity platinum crucibles? Ensure Absolute Data Integrity in Magnetite Oxidation

- What are the specific functions of the grinder and laboratory oven during sugarcane-based activated carbon preparation?

- What role does a laboratory graphite box play during the selenization of CBTSe thin films? Key Synthesis Benefits

- Why is a high-purity alumina (Al2O3) crucible required for the melting of nickel-based superalloys?

- What are the main features of a water circulating vacuum pump compared to a desktop pump? Discover Key Differences for Your Lab

- Why is a gas mixing system essential for syngas annealing in copper powder production? Ensure Precise Embrittlement