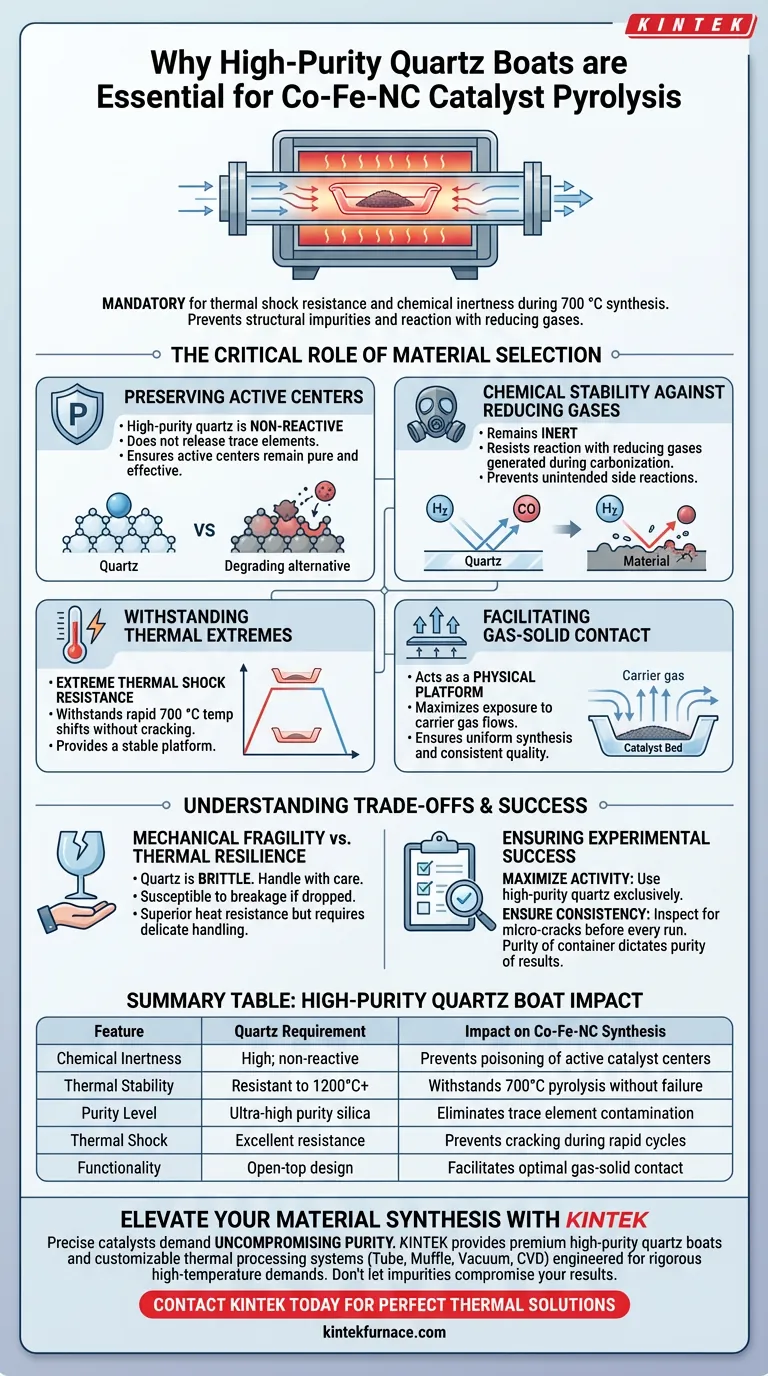

High-purity quartz boats are mandatory for this process because they provide the necessary thermal shock resistance and chemical inertness required for high-temperature synthesis. Specifically, they prevent the introduction of structural impurities during the 700 °C pyrolysis phase and refuse to react with the reducing gases generated during carbonization, thereby ensuring the chemical integrity of the Co-Fe-NC catalyst.

The choice of a quartz boat is not merely about holding the sample; it is a critical contamination-control measure. By remaining chemically inert at high temperatures, quartz preserves the precise active centers of the catalyst, whereas other materials might degrade or react with synthesis byproducts.

The Critical Role of Material Selection in Pyrolysis

Preserving the Active Centers

The primary goal during the synthesis of Co-Fe-NC catalysts is to establish specific, highly active sites. High-purity quartz is non-reactive, meaning it does not release trace elements or impurities when heated.

If a container releases even microscopic contaminants, they can poison the catalyst. Quartz ensures that the active centers formed during pyrolysis remain pure and effective.

Chemical Stability Against Reducing Gases

During carbonization, the breakdown of precursor materials generates reducing gases. A standard ceramic or metal container might react with these gases, altering the chemical composition of the environment.

Quartz possesses excellent chemical stability. It remains inert even when exposed to these reactive byproducts, preventing unintended side reactions that could degrade the catalyst's structure.

Withstanding Thermal Extremes

The pyrolysis process involves heating the material to approximately 700 °C. This temperature shift places immense stress on the carrier container.

Quartz is selected for its extreme thermal shock resistance. It can withstand the rapid temperature ramp-up and cool-down phases of the tube furnace without cracking or shattering, providing a stable platform throughout the reaction.

Facilitating Gas-Solid Contact

In addition to stability, the boat acts as a physical platform for the raw materials. It holds the precursors in a way that maximizes exposure to carrier gas flows.

This setup ensures optimal contact between the carbon source vapors and the catalyst bed. This interaction is essential for uniform synthesis and consistent catalyst quality.

Understanding the Trade-offs

Mechanical Fragility vs. Thermal Resilience

While quartz offers superior resistance to heat, it is mechanically brittle. It is highly susceptible to breakage if dropped or handled roughly during loading and unloading.

You must accept that while the material will not fail under heat, it requires delicate physical handling compared to sturdier, but less pure, alternatives like standard alumina or metal alloys.

Cost and Maintenance

High-purity quartz is a precision material and often comes at a higher cost than standard ceramics. It requires careful cleaning to maintain its transparency and purity over repeated uses.

However, using cheaper alternatives is a false economy in this context. The risk of batch contamination outweighs the initial savings on the carrier boat.

Ensuring Experimental Success

To maximize the performance of your Co-Fe-NC catalysts, adhere to the following guidelines regarding your equipment:

- If your primary focus is maximizing catalytic activity: Exclusively use high-purity quartz to ensure that absolutely no external impurities interfere with the formation of Co-Fe active centers.

- If your primary focus is process consistency: Ensure the boat is inspected for micro-cracks before every run, as the 700 °C thermal cycling can eventually fatigue even high-grade quartz.

Ultimately, the purity of your container dictates the purity of your results; compromise on the boat, and you compromise the catalyst.

Summary Table:

| Feature | High-Purity Quartz Boat Requirement | Impact on Co-Fe-NC Synthesis |

|---|---|---|

| Chemical Inertness | High; non-reactive with reducing gases | Prevents poisoning of active catalyst centers |

| Thermal Stability | Resistant up to 1200°C+ | Withstands 700°C pyrolysis without structural failure |

| Purity Level | Ultra-high purity silica | Eliminates trace element contamination |

| Thermal Shock | Excellent resistance | Prevents cracking during rapid ramp/cool cycles |

| Functionality | Open-top boat design | Facilitates optimal gas-solid contact for carbonization |

Elevate Your Material Synthesis with KINTEK

Precise catalysts demand uncompromising purity. KINTEK provides high-performance lab solutions backed by expert R&D and manufacturing. Our premium high-purity quartz boats, alongside our customizable Tube, Muffle, Vacuum, and CVD systems, are engineered to meet the rigorous demands of high-temperature pyrolysis and carbonization.

Don't let container impurities compromise your Co-Fe-NC active centers. Contact KINTEK today to find the perfect thermal processing equipment and high-purity accessories tailored to your unique research needs.

Visual Guide

References

- Dhayanantha Prabu Jaihindh, Chun-Yi Chen. Bimetallic and Magnetic CoFe-/Nitrogen-Doped Carbon Nanocomposites as Catalysts for the Degradation of Rhodamine B. DOI: 10.1021/acsanm.5c02849

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a graphite crucible play during alloy and ceramic shell interaction experiments? Optimize Your Lab Results

- Why are high-purity alumina crucibles selected as the substrate during the sintering of boron-containing stainless steel?

- What are the key characteristics of the circulating water multifunctional vacuum pump? Discover Clean, Oil-Free Lab Solutions

- Why are alumina (Al2O3) sample pans or crucibles essential for DSC testing of titanium alloys? Expert Insights

- How does a Mass Flow Controller (MFC) influence CrAlSiN coatings? Precision Ar/N2 Control for Hardness

- What core environmental protection does an argon-protected glove box provide for sodium-ion batteries? Maximize Safety

- Why is a vacuum pump used to evacuate the thermal modification chamber? Ensure Safety and Material Integrity

- Why are laboratory furnaces considered essential in industrial and scientific applications? Unlock Precision and Control for Your Materials