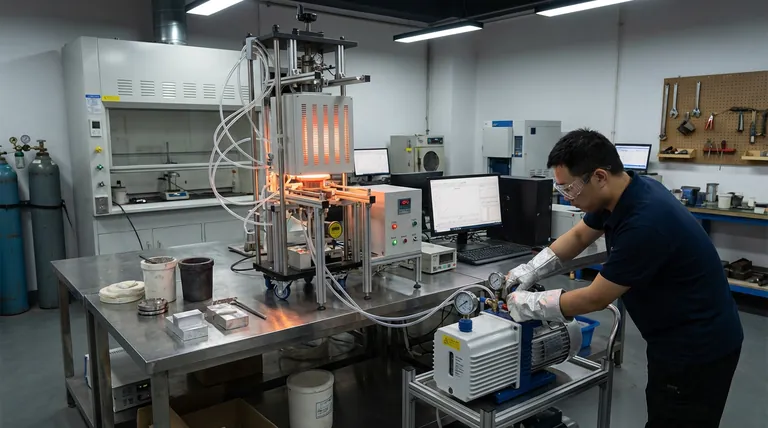

In simulated aluminum alloy refining, the vacuum pump serves as the critical control mechanism for environmental pressure. Its primary function is to actively reduce the chamber pressure from atmospheric levels (approximately 101 kPa) to a precise target, often as low as 0.97 kPa, to fundamentally alter the thermodynamic behavior of the melt.

Core Takeaway: By creating a low-pressure environment, the vacuum pump maximizes the thermodynamic driving force required to evaporate harmful impurities, achieving purification rates that are impossible under standard atmospheric conditions.

The Mechanics of Impurity Removal

Altering the Evaporation Threshold

The primary role of the vacuum pump is not simply to remove air, but to lower the boiling point of specific elements within the alloy.

By maintaining a controlled pressure (e.g., 0.97 kPa), the system significantly increases the driving force for the evaporation of volatile metallic impurities.

This facilitates a much higher evaporation rate, allowing for the efficient separation of unwanted elements from the aluminum base.

Clearing the Evaporation Path

In processes like aluminum-magnesium separation, the pump maintains high vacuum levels (often 10–15 Pa).

This effectively clears the "path" for vapor to escape, ensuring that evaporated atoms do not re-condense or saturate the immediate atmosphere above the melt.

Vacuum in Quality Simulation and Testing

The Reduced Pressure Test (RPT)

In laboratory simulations, the vacuum pump is used to artificially exaggerate defects for analysis.

By lowering ambient pressure, the pump forces dissolved gases (like hydrogen) to diffuse into internal double oxide films (bifilms).

Visualizing Hidden Defects

This expansion transforms curled, hard-to-detect defects into significant, visible cracks.

This process allows technical personnel to use X-ray inspection to accurately assess metal cleanliness and crack density, which would remain hidden at atmospheric pressure.

Environmental Stability and Protection

Preventing Oxidation

Before melting begins, mechanical pumps are often used to reach pressures as low as $10^{-2}$ Pa.

This creates a physical prerequisite for removing residual oxygen, preventing the oxidation of the aluminum and alloying elements like vanadium at high temperatures.

Stabilizing Alloying Elements

A stable vacuum environment prevents the liquid metal from absorbing gases from the atmosphere.

This stability is critical for ensuring that the addition of alloying elements is consistent and that the final material meets high-performance standards, such as those required in aerospace applications.

Understanding the Trade-offs

The Risk of Over-Evaporation

While high vacuum drives impurity removal, it lacks selectivity if not carefully managed.

An overly aggressive vacuum profile can lead to the unintended evaporation of desirable alloying elements (like Magnesium) if they have high vapor pressures, altering the alloy's target composition.

Equipment Complexity vs. Benefit

Achieving extremely low pressures (below 5 Pa) requires high-performance pumping systems.

While necessary for aerospace-grade purity, these systems introduce significant operational complexity and cost compared to standard refining methods.

Making the Right Choice for Your Goal

To optimize your vacuum refining simulation, align your pump's operation with your specific objective:

- If your primary focus is Purification: Prioritize a pump capable of reaching and sustaining specific low-pressure setpoints (e.g., 0.97 kPa) to maximize the evaporation rate of volatile impurities.

- If your primary focus is Defect Analysis: Ensure your system can rapidly lower pressure to expand trapped gases, making internal bifilms visible for RPT analysis.

- If your primary focus is Material Stability: Focus on deep evacuation (down to $10^{-2}$ Pa) prior to heating to eliminate oxygen and prevent gas absorption during the melt.

The vacuum pump is not just a removal tool; it is a thermodynamic lever that dictates the purity, structural integrity, and chemical composition of the final alloy.

Summary Table:

| Function | Key Mechanism | Process Benefit |

|---|---|---|

| Impurity Removal | Lowers boiling points & increases evaporation rate | Higher purification rates of volatile elements |

| Defect Analysis | Expands dissolved gases in bifilms (RPT) | Makes hidden cracks visible for X-ray inspection |

| Oxidation Control | Eliminates residual oxygen before melting | Protects alloy integrity and prevents metal loss |

| Environmental Stability | Prevents gas absorption from atmosphere | Ensures consistent chemical composition for aerospace |

| Vapor Path Clearing | Prevents atom re-condensation | Maintains high-speed evaporation for separation |

Elevate Your Metallurgical Research with KINTEK

Precision in aluminum alloy refining begins with reliable vacuum control. KINTEK provides industry-leading thermal and vacuum solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your specific simulation parameters.

Backed by expert R&D and advanced manufacturing, our equipment ensures the stable, low-pressure environments required for high-purity purification and accurate RPT defect analysis. Contact KINTEK today to discuss your unique laboratory needs and discover how our high-temperature furnace systems can enhance your material quality and research outcomes.

References

- Aleksandar M. Mitrašinović, Milinko Radosavljević. Modeling of Impurities Evaporation Reaction Order in Aluminum Alloys by the Parametric Fitting of the Logistic Function. DOI: 10.3390/ma17030728

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

People Also Ask

- What is the function of an in-situ heating holder in the study of Peierls transitions in NaRu2O4? Dynamic Lab Insights

- Why is a heating magnetic stirrer used for the acid activation of zeolites? Precision in Thermal & Kinetic Control

- What role do laboratory furnaces play in quality control? Ensure Material Integrity and Product Reliability

- What function does a laboratory blast drying oven perform? Optimize Pretreatment for Magnetic Particles

- What are the requirements for sealed quartz tubes for CVT? Ensure High Purity & Integrity for NiI2 and MnPS3 Growth

- What role does a high-precision infrared thermometer play in double-glow plasma metallurgy? Ensuring Precision & Protecting Materials

- How do cooling modules in high-temperature laboratory furnaces manage thermal energy? Protect Your System Components

- What is lab vacuum used for? Mastering Environmental Control for Purity and Precision