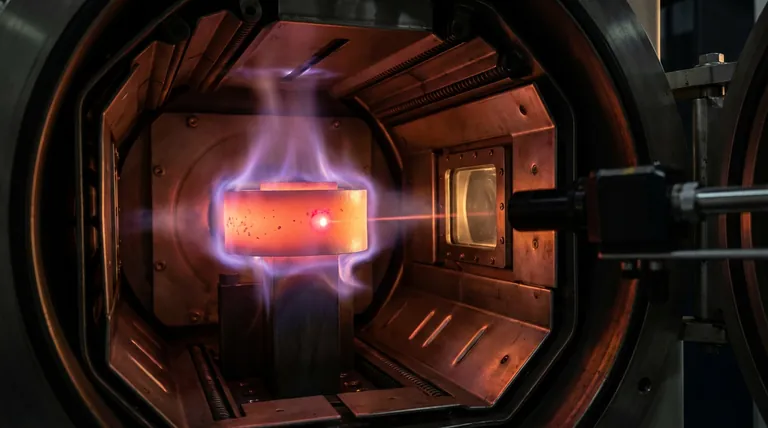

A high-precision infrared thermometer serves as the central feedback mechanism for the double-glow plasma surface metallurgy process. It facilitates real-time, non-contact monitoring of the workpiece's surface temperature directly inside the furnace. This continuous stream of thermal data is essential for triggering specific chemical reactions and preserving the structural integrity of the metal.

Core Takeaway Success in plasma surface metallurgy relies less on generating heat and more on precise thermal regulation. The infrared thermometer acts as the process "gatekeeper," ensuring chemical reactions like nitriding occur at the exact moment required while preventing excessive heat from degrading the substrate's mechanical properties.

The Mechanics of Process Control

Real-Time Monitoring

The environment inside a double-glow plasma furnace is harsh and dynamic. A high-precision infrared thermometer allows operators to monitor the workpiece temperature continuously without physical contact. This real-time data stream eliminates guesswork, providing an accurate reading of the surface conditions at every second.

Triggering Chemical Reactions

Temperature acts as the catalyst for specific metallurgical phases. In this process, precise thermal thresholds dictate when reactive elements are introduced. For example, the system uses the thermometer's data to trigger the introduction of nitrogen for reaction nitriding exactly when the temperature reaches 500°C.

Protecting Material Integrity

Preserving Phase Structure

The ultimate goal of surface metallurgy is to modify the surface without ruining the core. If the furnace temperature rises unchecked, the heat can alter the phase structure of the valve substrate. Accurate monitoring ensures the surface modification is effective while the underlying crystalline structure remains stable.

Maintaining Substrate Properties

The base material (substrate) was chosen for specific mechanical properties, such as strength or ductility. Excessive heat can degrade these inherent properties, rendering the component useless despite a treated surface. The infrared thermometer prevents this by ensuring the process stays within a thermal window that modifies the surface but spares the core.

The Risks of Thermal Deviation

The Cost of Inaccuracy

Without the precision of an infrared thermometer, the process becomes a gamble. A deviation of even a few degrees during critical phases can lead to incomplete nitriding or "over-cooking" the metal. This results in a compromised component that may look correct on the surface but lacks the required structural integrity.

Balancing Reaction vs. Retention

There is a constant trade-off between heat required for reaction and the heat limit of the substrate. The thermometer allows you to walk this fine line. It ensures the temperature is high enough to induce the necessary chemical diffusion but low enough to prevent thermal distortion or phase transformation in the base metal.

Making the Right Choice for Your Goal

To apply this to your own manufacturing or quality control processes, consider your primary objective:

- If your primary focus is Surface Hardness: Rely on the thermometer to pinpoint the exact moment (e.g., 500°C) to introduce nitrogen to maximize the nitriding effect.

- If your primary focus is Component Longevity: Use the thermometer to set strict upper-limit alarms to prevent the phase structure of the substrate from degrading.

Precision in temperature measurement is the only barrier between a successfully modified surface and a ruined substrate.

Summary Table:

| Key Function | Impact on Process & Material |

|---|---|

| Real-Time Monitoring | Provides continuous, non-contact surface temperature data. |

| Triggering Reactions | Ensures precise thermal thresholds for chemical reactions (e.g., nitriding). |

| Material Preservation | Prevents phase structure degradation and maintains substrate properties. |

| Risk Mitigation | Avoids costly inaccuracies, incomplete reactions, and component damage. |

| Process Optimization | Balances reaction temperature needs with material integrity limits. |

Achieve unparalleled precision and safeguard your materials in high-temperature processes. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs, including advanced thermal monitoring. Discover how our solutions can enhance your manufacturing and quality control—contact us today!

References

- Changzeng Luo, Shengguan Qu. Impact Wear Behavior of the Valve Cone Surface after Plasma Alloying Treatment. DOI: 10.3390/app14114811

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the maximum vacuum capacity of the water circulating vacuum pump? Uncover Its Ideal Lab Applications

- What factors should be considered when selecting an alumina ceramic furnace tube? Ensure Safety and Performance in High-Temp Processes

- What chemical resistance properties should be verified for alumina ceramic furnace tubes? Ensure High-Temperature Durability

- What are the advantages of a water circulating vacuum pump? Superior for Wet, Corrosive Gas Handling

- What is the advantage of the circulating water multifunctional vacuum pump being one machine for multiple purposes? Streamline Lab Work Efficiently

- What is the function of a water-cooled copper crucible? Master High-Purity Alloy Synthesis with KINTEK

- What are the limitations of ultra-pure alumina porcelain tubes? Manage Brittleness for Reliable High-Temp Use

- What is the function of Mass Flow Controllers (MFC) in the gas proportioning process for co-combustion experiments?