At its core, a water circulating vacuum pump offers significant advantages in simplicity, operational robustness, and the ability to handle contaminated gas streams. Unlike pumps that rely on tight mechanical tolerances or oil for sealing, its design uses a rotating ring of water to create a vacuum, making it inherently resistant to vapors and particulates that would damage or contaminate other pump types.

The primary advantage of a water circulating vacuum pump is not its vacuum depth, but its exceptional tolerance for wet, corrosive, and solvent-laden gases. Its unique operating principle makes it a reliable workhorse for applications where other pumps would quickly fail or require extensive maintenance.

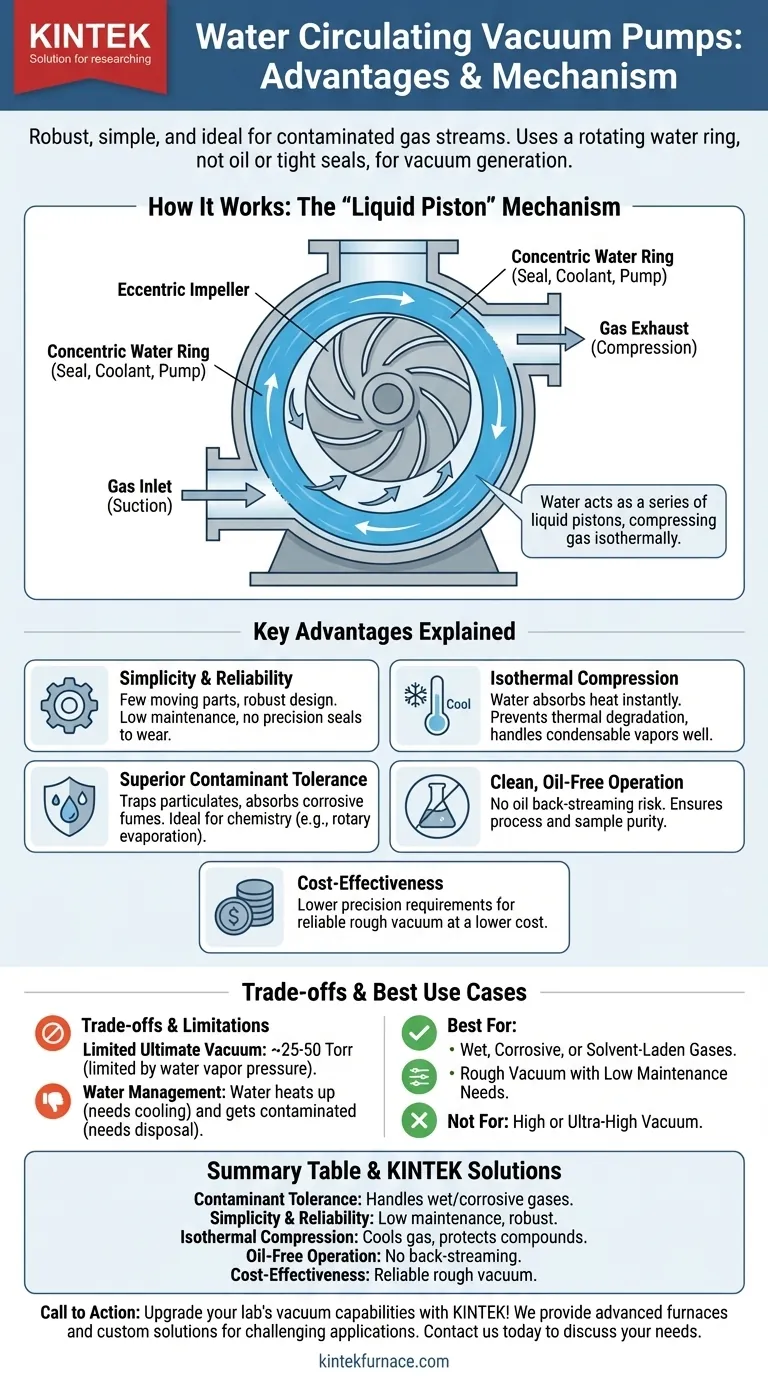

How It Works: The "Liquid Piston"

To understand its advantages, you must first understand its mechanism. This pump does not rely on complex, tightly-machined moving parts to create a vacuum.

The Core Mechanism

A water circulating vacuum pump, also known as a water ring pump, uses an impeller that is mounted eccentrically (off-center) inside a cylindrical casing.

As the pump operates, it draws water from a reservoir and spins it, causing centrifugal force to form a consistent, concentric ring of water against the outer wall of the casing.

The Pumping Action

Because the impeller is off-center, the space between the impeller blades and the surface of the water ring continuously changes.

Where the blades are moving away from the water ring, the volume expands, drawing in gas from the inlet port. As the blades rotate toward the water ring, the volume shrinks, compressing the gas and forcing it out of the exhaust port. This action effectively uses the water as a series of liquid pistons.

The Triple Role of Water

The circulating water is the key to the entire system. It simultaneously serves three critical functions: it creates the seal between the impeller and the casing, it cools the compressed gas, and it acts as the pumping mechanism itself.

Key Advantages Explained

This unique design gives rise to several distinct operational advantages over other mechanical pumps, such as oil-sealed rotary vane or dry scroll pumps.

Inherent Simplicity and Reliability

The design has very few moving parts in direct contact, with generous clearances. This means it has low precision manufacturing requirements, leading to a simpler, more robust, and cost-effective construction.

This simplicity translates directly to high reliability and easy maintenance. There are no delicate tips or seals to wear out and no oil to change.

Isothermal Compression

As gas is compressed, it heats up. In a water ring pump, this heat is immediately absorbed by the large volume of circulating water. This near-isothermal compression is a massive advantage.

It prevents the thermal degradation of sensitive compounds being pumped and, most importantly, allows the pump to easily handle large volumes of condensable vapors (like solvents) without a significant loss in performance.

Superior Contaminant and Vapor Tolerance

This is arguably the pump's most important feature. The constant flow of water can trap particulates and absorb corrosive fumes, protecting the pump's internal components.

It excels at pumping gas streams containing vapors that would contaminate the oil in an oil-sealed pump or damage the seals in a dry pump. This makes it ideal for chemistry applications like rotary evaporation and reactor evacuation.

Clean, Oil-Free Operation

Because water is the sealing fluid, there is no oil in the vacuum-generating mechanism. This completely eliminates the risk of "back-streaming," where oil vapor migrates from the pump back into your vacuum system, contaminating your process or sample.

Understanding the Trade-offs and Limitations

No technology is perfect. A water circulating pump's strengths in some areas create limitations in others.

Limited Ultimate Vacuum

The ultimate vacuum this pump can achieve is physically limited by the vapor pressure of the water itself, which is dependent on its temperature.

Typically, these pumps cannot achieve pressures much lower than 25-50 Torr (33-67 mbar). This is significantly less deep than the vacuum levels achievable with oil-sealed or dry pumps, which can reach pressures orders of magnitude lower.

Water Management

While "circulating" systems save vast amounts of water compared to once-through designs, the water is still a consumable. It will heat up during use, reducing efficiency, and may require an external chiller for continuous, heavy-duty operation.

Furthermore, any solvents or acids pumped will accumulate in the water, requiring periodic changes and proper disposal of the contaminated water.

Making the Right Choice for Your Application

Selecting a vacuum pump is about matching the tool to the specific demands of your process.

- If your primary focus is handling wet, corrosive, or solvent-laden gases: The water circulating pump is an excellent, robust choice due to its isothermal compression and tolerance for contaminants.

- If your primary focus is achieving a high or ultra-high vacuum: This pump is unsuitable; you must consider an oil-sealed rotary vane, scroll, turbo, or ion pump.

- If your primary focus is simplicity and low maintenance for rough vacuum: The water circulating pump's simple design makes it a reliable and cost-effective workhorse for applications that do not require deep vacuum levels.

Ultimately, understanding this pump's core principle of using a liquid ring empowers you to leverage its strengths for the right applications.

Summary Table:

| Advantage | Description |

|---|---|

| Contaminant Tolerance | Handles wet, corrosive, and solvent-laden gases without damage or contamination. |

| Simplicity & Reliability | Few moving parts, low maintenance, and no oil changes for long-lasting performance. |

| Isothermal Compression | Water cools gas during compression, preventing thermal degradation of sensitive compounds. |

| Oil-Free Operation | Eliminates back-streaming risk, ensuring clean vacuum for processes and samples. |

| Cost-Effectiveness | Robust design with low precision requirements, offering reliable rough vacuum at lower cost. |

Upgrade your lab's vacuum capabilities with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental needs, especially for handling challenging gas streams. Contact us today to discuss how our reliable pumps and furnaces can enhance your efficiency and results!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What role do quartz tubes and vacuum sealing play in synthesis? Master High-Reactivity Compounds like U0.92Mn3Si2C

- Why use a PLC and touch screen for magnesium vacuum distillation? For Superior Control and Safety

- Why are high-purity ceramic boats used for V2O5 and VSe2 deposition? Ensure Film Purity and Thermal Stability

- What is the purpose of cleaning MgO substrates for ScN growth? Optimize Your Epitaxial Film Quality

- Why is a sealing lid necessary for the clay-graphite crucible? Key to Successful Fe3O4/C Composite Synthesis

- What are the roles of laboratory vacuum drying ovens and precision analytical balances in moisture monitoring?

- What role does a laboratory vacuum pump play in a static batch desulfurization evaluation system? Ensure Data Integrity

- What are the maximum working pressure specifications for water circulating vacuum pumps? Ensure Safe Operation and Avoid Failure