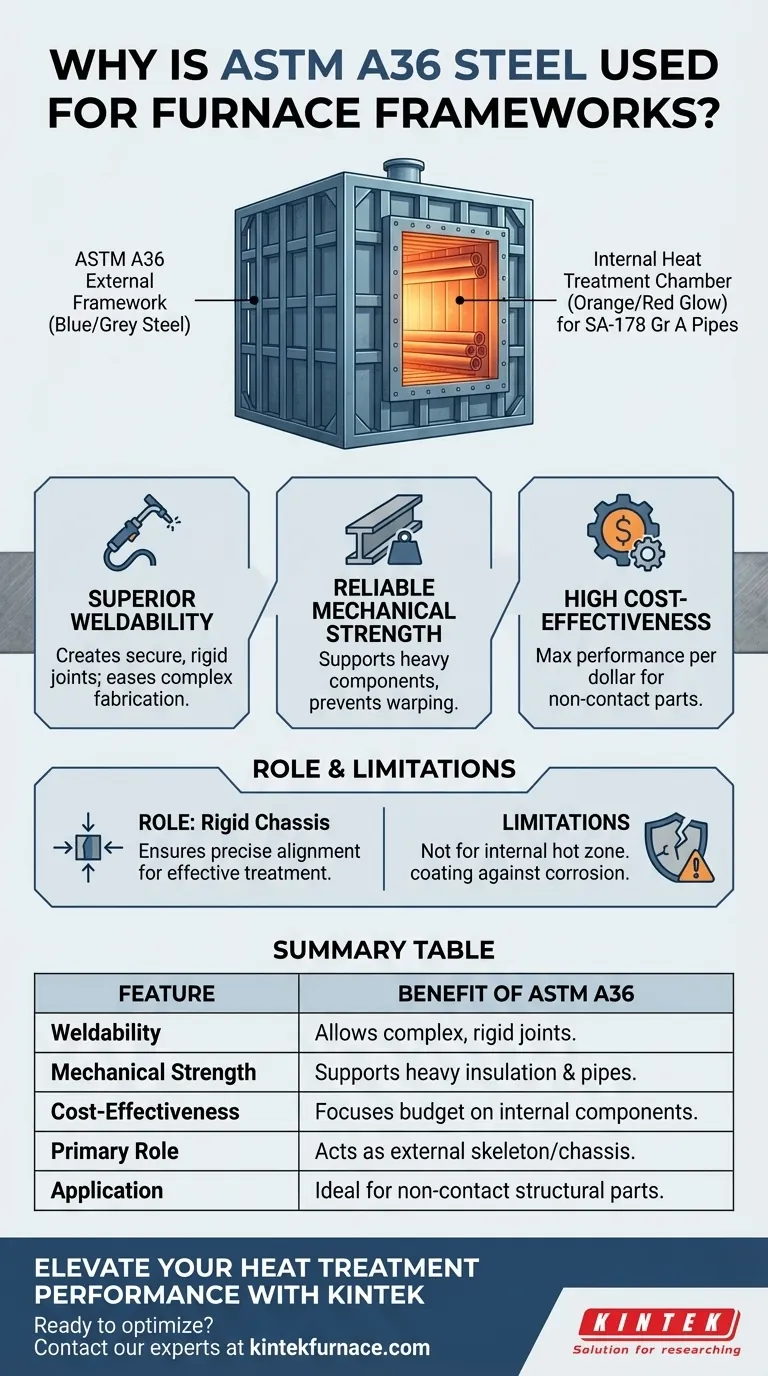

ASTM A36 carbon steel plate is the standard choice for the external structural framework of heat treatment furnaces due to its exceptional combination of weldability, mechanical strength, and cost-effectiveness. It acts as the physical skeleton of the equipment, ensuring the heavy furnace assembly maintains structural integrity while supporting the high-temperature operations required to treat SA-178 Gr A pipes.

While the interior of the furnace is designed for intense heat to normalize steel pipes, the external framework demands rigidity and ease of fabrication rather than thermal resistance. ASTM A36 provides the structural stability needed to house this process without the unnecessary expense of exotic alloys.

The Pillars of Material Selection

Superior Weldability

The construction of large industrial furnaces requires complex fabrication. ASTM A36 is renowned for its excellent weldability, allowing engineers to create secure, rigid joints without sophisticated welding procedures. This facilitates the construction of a durable frame capable of housing heavy electrical and thermal components.

Reliable Mechanical Strength

A heat treatment furnace is a heavy industrial asset. The ASTM A36 plate provides dependable mechanical strength, ensuring the framework remains rigid under the weight of the insulation, heating elements, and the piping being treated. This strength prevents warping or structural failure during long-term industrial use.

High Cost-Effectiveness

For the external structure, using high-alloy heat-resistant steel is often an unnecessary expenditure. ASTM A36 offers maximum structural performance per dollar, allowing the budget to be focused on critical internal components like heating elements and refractory linings.

Supporting the Heat Treatment Process

The Goal of the Operation

The furnace is designed to perform normalizing heat treatment on SA-178 Gr A steel pipes. This process involves precise heating to achieve microstructural homogenization and eliminate residual stresses.

The Role of the Framework

While the frame does not directly contact the pipes during the heating cycle, its stability is critical. By providing a rigid "chassis," the ASTM A36 structure ensures the precise alignment and safety of the heating chamber, allowing the pipes to be treated effectively to optimize ductility and toughness.

Understanding the Limitations

Not for Internal Linings

It is critical to distinguish between the external frame and the internal hot zone. ASTM A36 is not a refractory material; it is used for the external shell and support. If exposed directly to the normalizing temperatures used for SA-178 pipes, A36 would lose significant strength and oxidize rapidly.

Corrosion Considerations

ASTM A36 is a carbon steel and does not possess high corrosion resistance. While excellent for structural rigidity, the surface usually requires painting or coating to prevent rust, particularly in industrial environments where humidity or chemical vapors may be present.

Making the Right Choice for Your Project

The selection of ASTM A36 is driven by a balance of structural requirements and economic logic.

- If your primary focus is Structural Integrity: Rely on ASTM A36 for the external skeleton to ensure the furnace holds its shape under heavy loads.

- If your primary focus is Cost Optimization: Utilize A36 for all non-contact, external components to reduce material costs without sacrificing safety.

- If your primary focus is Fabrication Speed: Choose A36 to simplify the welding and assembly process during furnace construction.

By selecting ASTM A36, you ensure a solid foundation that allows the furnace to perform its critical metallurgical work safely and efficiently.

Summary Table:

| Feature | Benefit of ASTM A36 in Furnace Frameworks |

|---|---|

| Weldability | Allows for complex fabrication and rigid, secure joints without specialized procedures. |

| Mechanical Strength | Provides the structural integrity to support heavy insulation, heating elements, and pipes. |

| Cost-Effectiveness | High performance-to-cost ratio, allowing budget allocation for internal refractory components. |

| Primary Role | Acts as the external skeleton (chassis) to ensure precise alignment of the heating chamber. |

| Application | Ideal for non-contact structural components in SA-178 Gr A steel pipe treatment. |

Elevate Your Heat Treatment Performance with KINTEK

Building high-performance furnaces requires the perfect balance of structural stability and advanced thermal technology. Backed by expert R&D and manufacturing, KINTEK offers high-quality Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique industrial requirements. Whether you are treating SA-178 Gr A pipes or developing specialized materials, our lab and industrial furnaces provide the precision and durability you need.

Ready to optimize your thermal processes? Contact our experts today to discuss your custom furnace needs and see how KINTEK’s engineering excellence can drive your success.

Visual Guide

References

- Gustavo Ribeiro Zanini, LUIS CARLOS GERON. PROJETO DE UM FORNO ELÉTRICO INDUSTRIAL PARA TRATAMENTO TÉRMICO TUBOS DE AÇO SA-178 GR A. DOI: 10.52138/citec.v17i01.437

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Stainless Steel KF ISO Vacuum Flange Blind Plate for High Vacuum Systems

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

People Also Ask

- Why use a vacuum sealing device for nickelate thin films? Master the Infinite-Layer Reduction Process

- What is the standard procedure for using a laboratory precision oven to determine the Total Solids (TS) of biomass?

- What role do high-purity graphite crucibles play in Boron Carbide sintering? Optimize Ceramic Purity and Density

- Why is a quartz boat required during APCVD for MoO2? Ensure High-Purity Single-Crystal Nanobelt Synthesis

- How do the quartz crucible and descending device function in Bridgman method? Precision Growth for CsPbBr3 Crystals

- What functions do high-purity sulfur powder and ceramic boats serve in TB-MoS2 prep? Precision in 2D Material Synthesis

- What is the maximum temperature for a quartz tube? Ensure Safe & Reliable High-Temp Processes

- What is the primary function of the vacuum pump system in the magnesium powder evaporation process? Ensure High Purity & Efficiency