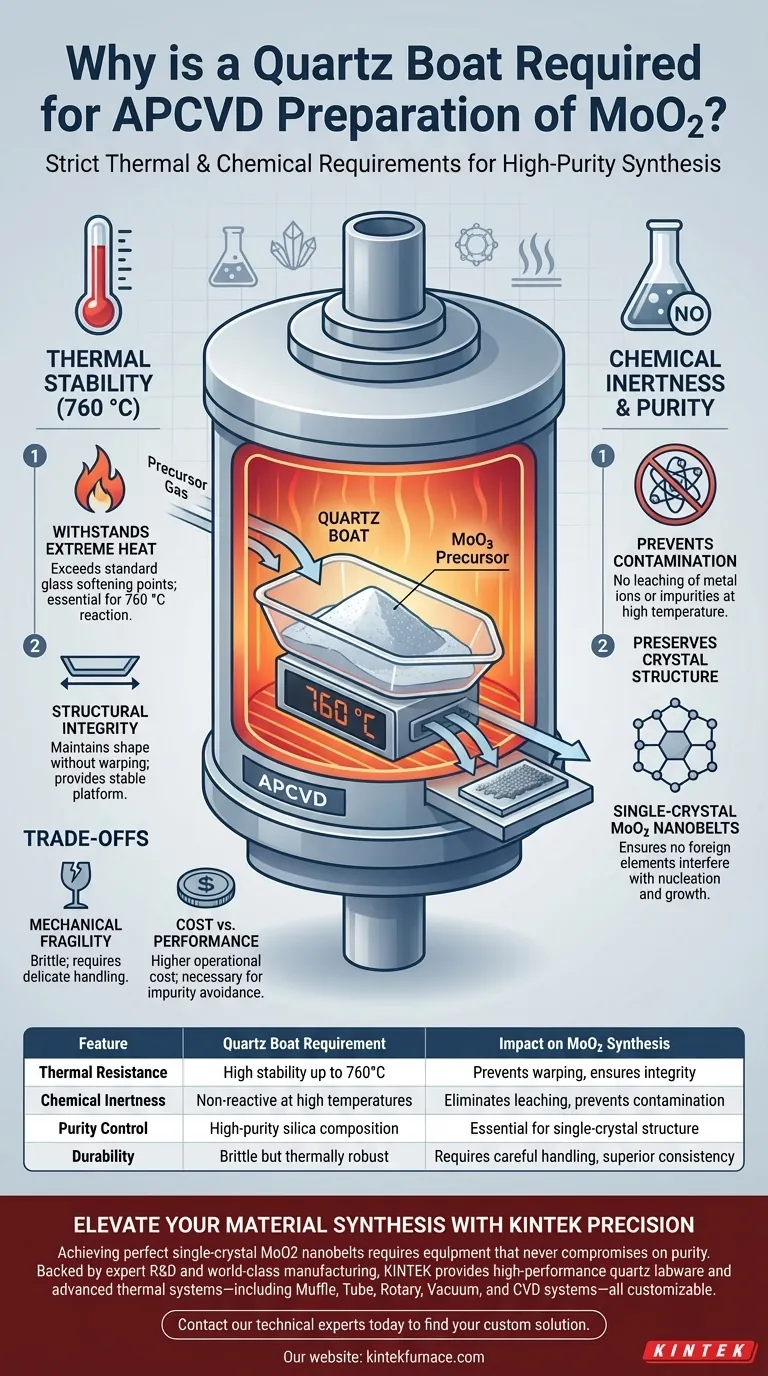

The selection of a quartz boat is a mandatory constraint in the Atmospheric Pressure Chemical Vapor Deposition (APCVD) preparation of Molybdenum Dioxide (MoO2) due to the strict thermal and chemical requirements of the synthesis. It is the only standard carrier capable of withstanding the 760 °C reaction temperature while preventing the leaching of metal ions that would degrade the purity and structure of the final product.

In precision nanomaterial synthesis, the reaction vessel is not a passive container but an active variable in the experiment's success. Quartz is utilized specifically because it remains chemically inert at high temperatures, ensuring the single-crystal structure of the nanobelts is preserved.

The Critical Role of Thermal Stability

Withstanding Extreme Heat

The APCVD process requires heating the MoO3 precursor powder to 760 °C. This temperature exceeds the softening point of many standard laboratory glasses and approaches the limits of various lower-grade ceramics.

Structural Integrity

At these elevated temperatures, a quartz boat maintains its rigidity and shape. It provides a stable platform for the precursor throughout the duration of the reaction without warping or degrading.

Chemical Inertness and Purity

Preventing Contamination

The primary objective of this synthesis is to grow high-purity MoO2 nanobelts. Using carriers made of metal or less stable ceramics introduces a significant risk of contamination.

Eliminating Leached Ions

At 760 °C, many materials release trace metal ions or other impurities into the reaction chamber. These impurities can act as unintentional dopants or defects.

Preserving Crystal Structure

The growth of a single-crystal structure is highly sensitive to the chemical environment. By using a quartz boat, you ensure that no foreign elements interfere with the nucleation and growth of the nanobelts.

Understanding the Trade-offs

Mechanical Fragility

While quartz offers superior thermal and chemical resistance, it is mechanically brittle. Unlike metal boats, quartz requires delicate handling during loading and unloading to avoid chipping or catastrophic breakage.

Cost vs. Performance

High-purity quartz labware represents a higher operational cost compared to standard ceramics or alumina boats. However, this cost is a necessary trade-off to avoid the batch failures associated with impurity introduction.

Ensuring Successful Synthesis

To guarantee the quality of your MoO2 nanobelts, you must prioritize the integrity of your carrier equipment.

- If your primary focus is High-Fidelity Crystal Growth: You must use a quartz boat to prevent metal ion contamination and ensure single-crystal formation.

- If your primary focus is Process Consistency: You should regularly inspect the quartz boat for surface degradation or micro-fractures that could harbor contaminants between runs.

By eliminating the carrier as a source of error, you isolate the reaction variables to just temperature and precursor chemistry.

Summary Table:

| Feature | Quartz Boat Requirement | Impact on MoO2 Synthesis |

|---|---|---|

| Thermal Resistance | High stability up to 760°C+ | Prevents warping and ensures structural integrity during reaction. |

| Chemical Inertness | Non-reactive at high temperatures | Eliminates leaching of metal ions and prevents contamination. |

| Purity Control | High-purity silica composition | Essential for achieving high-fidelity single-crystal structures. |

| Durability | Brittle but thermally robust | Requires careful handling but provides superior process consistency. |

Elevate Your Material Synthesis with KINTEK Precision

Achieving perfect single-crystal MoO2 nanobelts requires equipment that never compromises on purity. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance quartz labware and advanced thermal systems—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to your specific research parameters.

Don't let carrier contamination ruin your high-temperature experiments. Partner with KINTEK for reliable, high-purity solutions tailored to your lab's unique needs.

Contact our technical experts today to find your custom solution

Visual Guide

References

- Haojian Lin, Wenjing Zhang. Facet‐Engineered (100)‐Oriented MoO <sub>2</sub> Nanoribbons for Broadband Self‐Powered Photodetection. DOI: 10.1002/advs.202510753

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does a laboratory blast drying oven facilitate BCZT gel drying? Precision Solutions for High-Quality Xerogels

- What is the purpose of a water circulating vacuum pump? Achieve Clean, Efficient Vacuum for Lab Processes

- What are the advantages of using alumina (Al2O3) crucibles for the high-temperature pyrolysis of Bakelite?

- What is the primary function of a quartz tube in SnSe preparation? Ensure High-Purity Alloy Synthesis

- What are the benefits of sealing SAC305 solder in vacuum quartz tubes? Ensure High-Reliability Alloy Integrity

- What functions do high-purity graphite crucibles serve in tantalum carbide synthesis? Essential Thermal & Chemical Roles

- What is the water-saving benefit of using a water circulating vacuum pump? Save Over 10 Tons of Water Daily

- What is the primary function of vacuum quartz tubes in Bi-Sb alloy preparation? Ensure Purity & Precise Stoichiometry