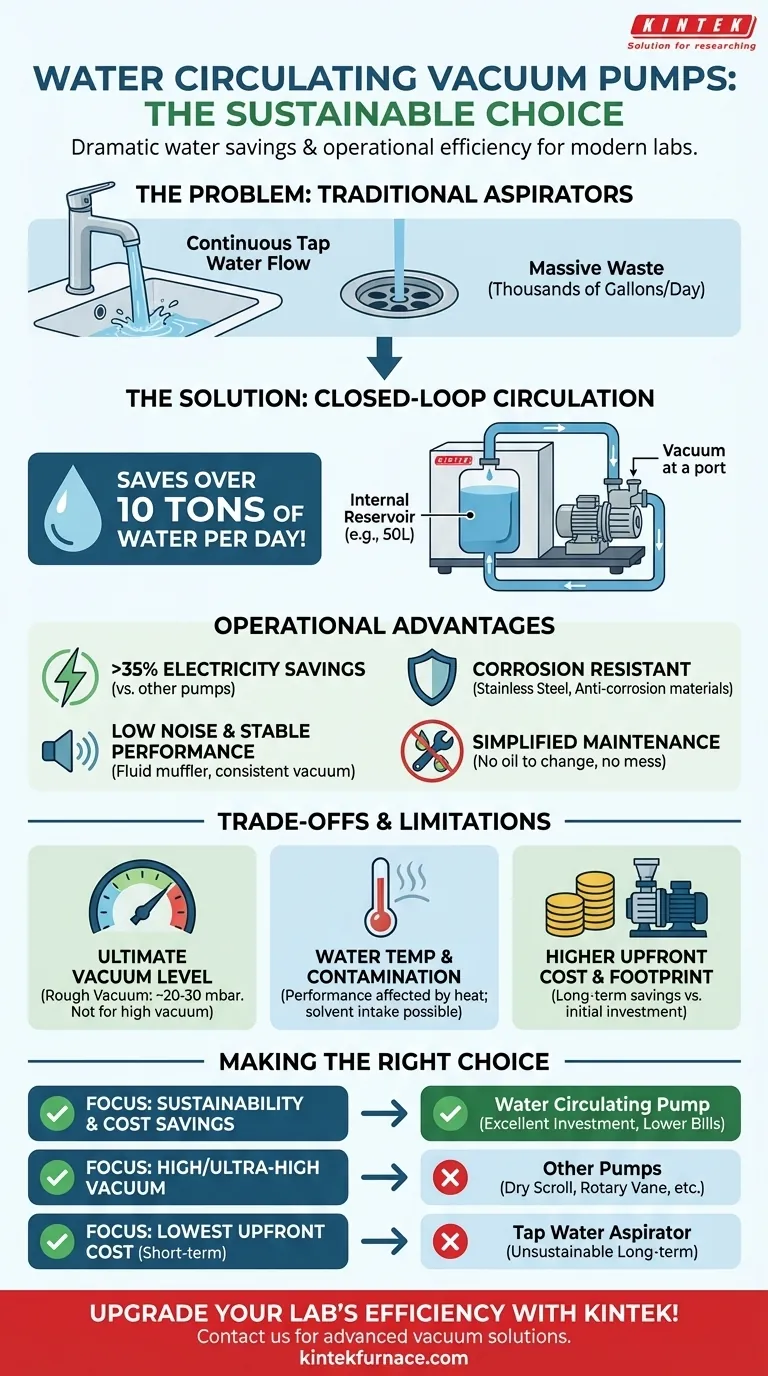

At its core, a water circulating vacuum pump provides substantial water-saving benefits by using a closed-loop system. Instead of continuously consuming and discarding tap water like a traditional aspirator, it recycles a fixed volume of water from an internal tank, potentially saving over 10 tons of water in a single day of operation.

The primary benefit is dramatic water conservation, but the deeper value lies in its overall operational efficiency. This type of pump reduces total utility costs—both water and electricity—while offering a more stable, quiet, and low-maintenance solution compared to other common vacuum sources.

How a Circulating Pump Achieves Savings

The design of a water circulating vacuum pump is fundamentally different from a standard tap water aspirator, which is the key to its efficiency.

The Closed-Loop Principle

A traditional water aspirator attaches directly to a faucet. To create a vacuum, it must run water continuously, all of which goes directly down the drain.

A circulating pump, by contrast, contains its own water reservoir (e.g., a 50-liter tank). The pump moves this same water through the vacuum-generating mechanism and back into the tank, creating a closed loop.

This means water consumption is limited to the initial fill and minimal losses from evaporation.

Quantifying the Impact

The most significant advantage is the sheer volume of water saved. For laboratories or facilities where a vacuum is needed for hours at a time, a tap aspirator can waste thousands of gallons per day.

The claim of saving over 10 tons of water in a working day highlights the immense difference. This translates directly to lower utility bills and makes it an essential tool in areas with water scarcity or high water costs.

Beyond Water: The Operational Advantages

While water conservation is the headline feature, the practical benefits extend to energy use, durability, and user convenience, making it a superior choice over both tap aspirators and oil-sealed pumps for many applications.

Significant Energy Efficiency

These pumps are engineered for efficiency. References indicate they can save more than 35% of electricity compared to other vacuum pump types, further reducing long-term operational costs.

Chemical and Corrosion Resistance

Many models are built with a stainless steel main engine and other anti-corrosion materials. This makes them resistant to the acids, alkalis, and solvents commonly used in laboratory settings, preventing damage and contamination.

This is a distinct advantage over oil pumps, where corrosive vapors can degrade the oil and damage internal components.

Lower Noise and Stable Performance

Equipped with a specialized fluid muffler, these pumps operate with very low noise, improving the work environment.

Furthermore, because the recycled water pressure is controlled and stable, the resulting vacuum level is more consistent than that from a tap aspirator, which can fluctuate with building water pressure.

Simplified Maintenance and Use

Compared to an oil-sealed mechanical pump, a water circulating pump is far simpler. There is no oil to change, no risk of oil leaks, and no messy oil mist to manage.

Features like casters for mobility, double taps for simultaneous use, and integrated vacuum gauges enhance their practicality in a shared lab space.

Understanding the Trade-offs and Limitations

No single technology is perfect for every scenario. To make an informed decision, it is critical to understand the limitations of a water circulating pump.

Ultimate Vacuum Level

The vacuum created by this type of pump is limited by the vapor pressure of the water in the tank. This typically results in a rough vacuum (e.g., around 20-30 mbar, or ~15-25 Torr).

This is perfectly adequate for applications like rotary evaporation, filtration, and degassing, but it is not suitable for high-vacuum processes that require pressures below 1 mbar.

Water Temperature and Contamination

The pump's efficiency depends on the water temperature. As the water heats up from use, its vapor pressure rises, which degrades the ultimate vacuum level. Some applications may require a chiller to maintain performance.

Additionally, volatile solvents from your experiment can be drawn into the water. This contaminates the reservoir and can reduce pump efficiency or be released into the lab atmosphere.

Upfront Cost and Footprint

A self-contained circulating pump has a higher initial purchase price and a larger physical footprint than a simple, inexpensive tap water aspirator. The savings are realized over time through lower utility and maintenance costs.

Making the Right Choice for Your Application

Choosing the correct vacuum source depends entirely on your specific experimental needs, budget, and facility resources.

- If your primary focus is sustainability and long-term cost savings for general lab work: A water circulating pump is an excellent investment, balancing solid performance with drastically lower utility bills.

- If your primary focus is achieving a high or ultra-high vacuum: This pump is not suitable; you must consider a dry scroll, oil-sealed rotary vane, or turbomolecular pump.

- If your primary focus is the absolute lowest upfront cost and water usage is not a concern: A simple tap water aspirator can suffice for infrequent, short-duration tasks, but it is an unsustainable and costly long-term solution.

Ultimately, a water circulating vacuum pump represents a strategic investment in operational efficiency and sustainability for the modern laboratory.

Summary Table:

| Feature | Benefit |

|---|---|

| Water Savings | Saves over 10 tons of water per day in a closed-loop system |

| Energy Efficiency | Reduces electricity use by more than 35% compared to other pumps |

| Operational Advantages | Low noise, stable vacuum, corrosion resistance, no oil changes |

| Limitations | Rough vacuum (20-30 mbar), not for high-vacuum processes |

Upgrade your lab's efficiency and sustainability with KINTEK's advanced vacuum solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to learn how our products can save you water, reduce costs, and enhance performance!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a mass flow controller (MFC) play in gas distribution? Ensure Precision in Sensor Performance Evaluation

- What role do high-purity graphite molds and punches play during the sintering of silicon carbide ceramics in SPS?

- Why is a glassy carbon boat preferred over an alumina crucible for Na3Cu4Se4? Ensuring Phase Purity in Flux Synthesis

- What is the primary function of an alumina crucible in preparing B2O3–ZnO–BaO shielding glass? Process Secrets Revealed

- What industrial applications utilize quartz tubes? Essential for High-Temp, Pure Processes

- What is Alumina and how is it derived? Discover Its Role in Advanced Materials and Production

- What role does a rotary evaporator play in microalgae-based nanomaterials? Protect Bio-Reductive Activity for Synthesis

- Why is a molybdenum crucible considered an ideal choice for quartz melting? High-Purity Solutions at 2000°C