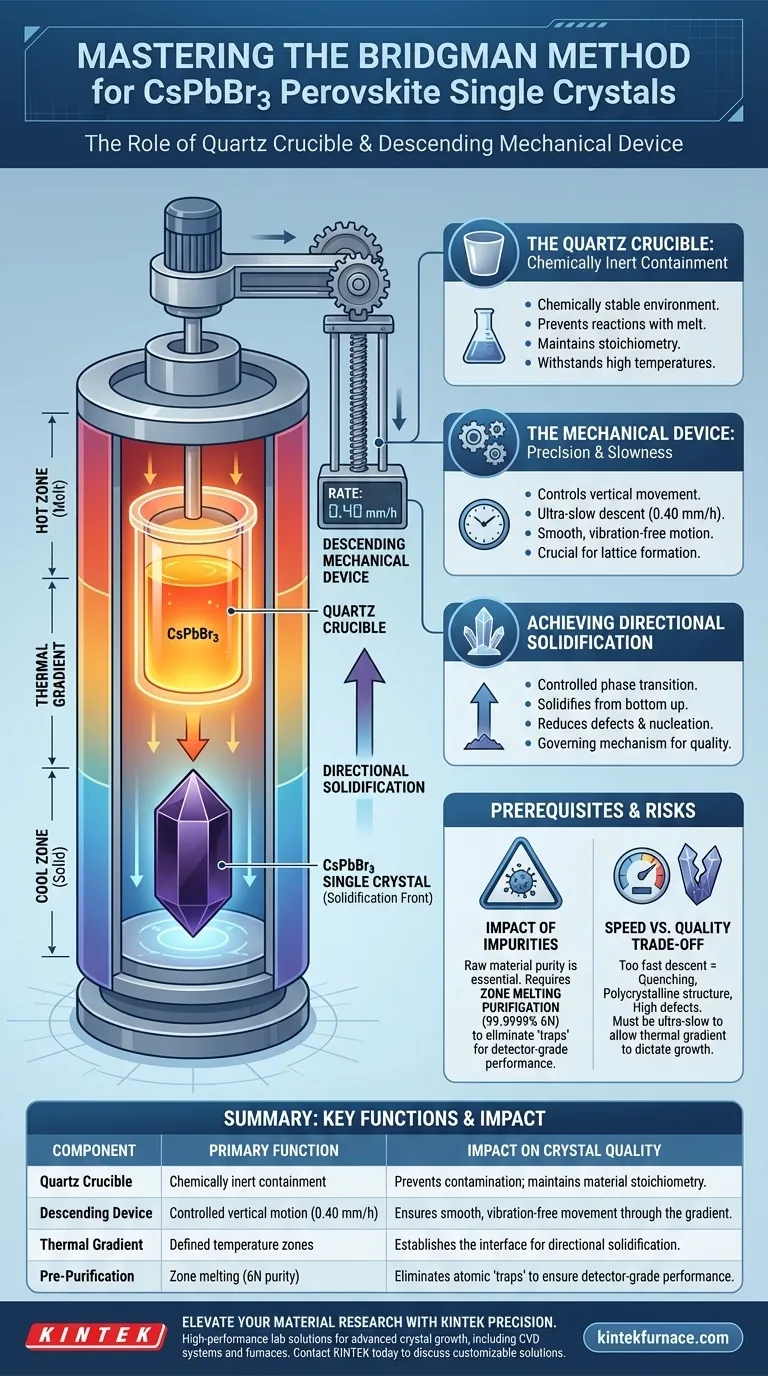

In the Bridgman growth method for CsPbBr3 crystals, the quartz crucible functions as a chemically inert vessel that contains the melt, while the descending mechanical device physically lowers this vessel through a fixed temperature gradient. This mechanical action is performed at a precisely controlled, ultra-slow rate—typically 0.40 mm/h—to force the molten material to solidify progressively from the bottom up.

The synergy between the chemically stable quartz environment and the precise mechanical descent creates the conditions for slow directional solidification. This controlled phase transition is the governing mechanism that ensures the resulting material becomes a high-quality single crystal with low defect density.

The Mechanics of High-Quality Crystal Growth

The Role of the Quartz Crucible

The quartz crucible provides a chemically stable growth environment. Because CsPbBr3 is processed at high temperatures, the containment vessel must withstand the heat without reacting with the melt.

By preventing chemical interactions between the container and the molten perovskite, the quartz ensures that the material retains its stoichiometry during the long growth cycle. This stability is the baseline requirement for successful crystallization.

Precision Control via the Mechanical Device

The descending mechanical device is the engine of the process, but its function is defined by slowness rather than power. It controls the crucible's vertical movement through specific temperature zones established within the furnace.

The reference rate of 0.40 mm/h highlights the extreme precision required. This device ensures the motion is smooth and constant, preventing vibrations or sudden shifts that could disrupt the crystal lattice formation.

Achieving Directional Solidification

The primary goal of lowering the crucible is to achieve directional solidification. As the mechanical device lowers the crucible, the bottom of the crucible exits the hot zone and enters a cooler zone first.

This causes the melt to solidify at the very bottom tip first. As the device continues to lower the crucible, the solidification interface moves slowly upward through the melt. This orderly progression allows the atoms to arrange themselves into a single, continuous crystal lattice, significantly reducing random nucleation and defects.

Understanding the Prerequisites and Risks

The Impact of Impurities

While the Bridgman method controls the structure of the crystal, it cannot fix a chemically impure input. The quartz crucible preserves purity, but it does not create it.

To achieve detector-grade performance (high linear dynamic range), the raw materials must undergo zone melting purification prior to Bridgman growth. This process refines materials to a 99.9999% (6N) purity level, eliminating impurity elements that would otherwise act as "traps" in the final crystal, regardless of how perfectly the mechanical device functions.

The Trade-off of Speed vs. Quality

The descent speed is a critical variable. The mechanical device must maintain a speed slow enough to allow the thermal gradient to dictate the crystallization front.

If the descent is too fast, the melt acts as if it is being quenched rather than grown. This leads to the formation of multiple small crystals (polycrystalline structure) or high defect densities, rendering the material unsuitable for high-performance applications.

Optimization for Detector-Grade Crystals

To maximize the potential of CsPbBr3 crystals for electronic applications, you must align your process parameters with your quality goals.

- If your primary focus is Defect Reduction: Ensure the mechanical device is calibrated to the slowest feasible rate (around 0.40 mm/h) to guarantee strict directional solidification.

- If your primary focus is Electronic Performance: Verify that the raw material loaded into the quartz crucible has strictly undergone zone melting purification to reach 6N grade purity before growth begins.

Ultimately, the quality of the final single crystal is dictated by the mechanical device's ability to maintain a steady, ultra-slow pace through the thermal gradient.

Summary Table:

| Component | Primary Function | Impact on Crystal Quality |

|---|---|---|

| Quartz Crucible | Chemically inert containment | Prevents contamination; maintains material stoichiometry. |

| Descending Device | Controlled vertical motion (0.40 mm/h) | Ensures smooth, vibration-free movement through the gradient. |

| Thermal Gradient | Defined temperature zones | Establishes the interface for directional solidification. |

| Pre-Purification | Zone melting (6N purity) | Eliminates atomic 'traps' to ensure detector-grade performance. |

Elevate Your Material Research with KINTEK Precision

High-performance crystals require unwavering thermal stability and mechanical precision. KINTEK provides industry-leading lab solutions tailored for advanced crystal growth, including CVD systems, Vacuum furnaces, and customizable high-temperature Muffle and Tube furnaces. Backed by expert R&D and specialized manufacturing, our equipment ensures the ultra-slow descent and strict thermal gradients necessary for your unique research needs.

Ready to optimize your Bridgman growth process? Contact KINTEK today to discuss our customizable furnace solutions.

Visual Guide

References

- Jincong Pang, Guangda Niu. Reconfigurable perovskite X-ray detector for intelligent imaging. DOI: 10.1038/s41467-024-46184-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What is the primary function of an alumina crucible in CsV3Sb5 growth? Ensure High Purity and Thermal Stability

- What is the function of a water quenching tank? Capturing Microstructures in Weather-Resistant Steel

- What are the common types and size ranges of Alumina ceramic tubing? Find the Perfect Fit for Your Lab

- What is the specific function of the water circulation cooler in zirconium sponge processing? Key for Purity & Safety

- What is the maximum vacuum capacity of the water circulating vacuum pump? Uncover Its Ideal Lab Applications

- Is it possible to tailor high-temperature laboratory furnaces? Custom Engineering for Unique Research Needs

- Why is a high-purity graphite crucible essential for magnesium vacuum distillation? Achieve Maximum Purity & Efficiency

- What is the role of specialized sealing ferrules in heating experiments? Ensure Hermetic Isolation and Purity