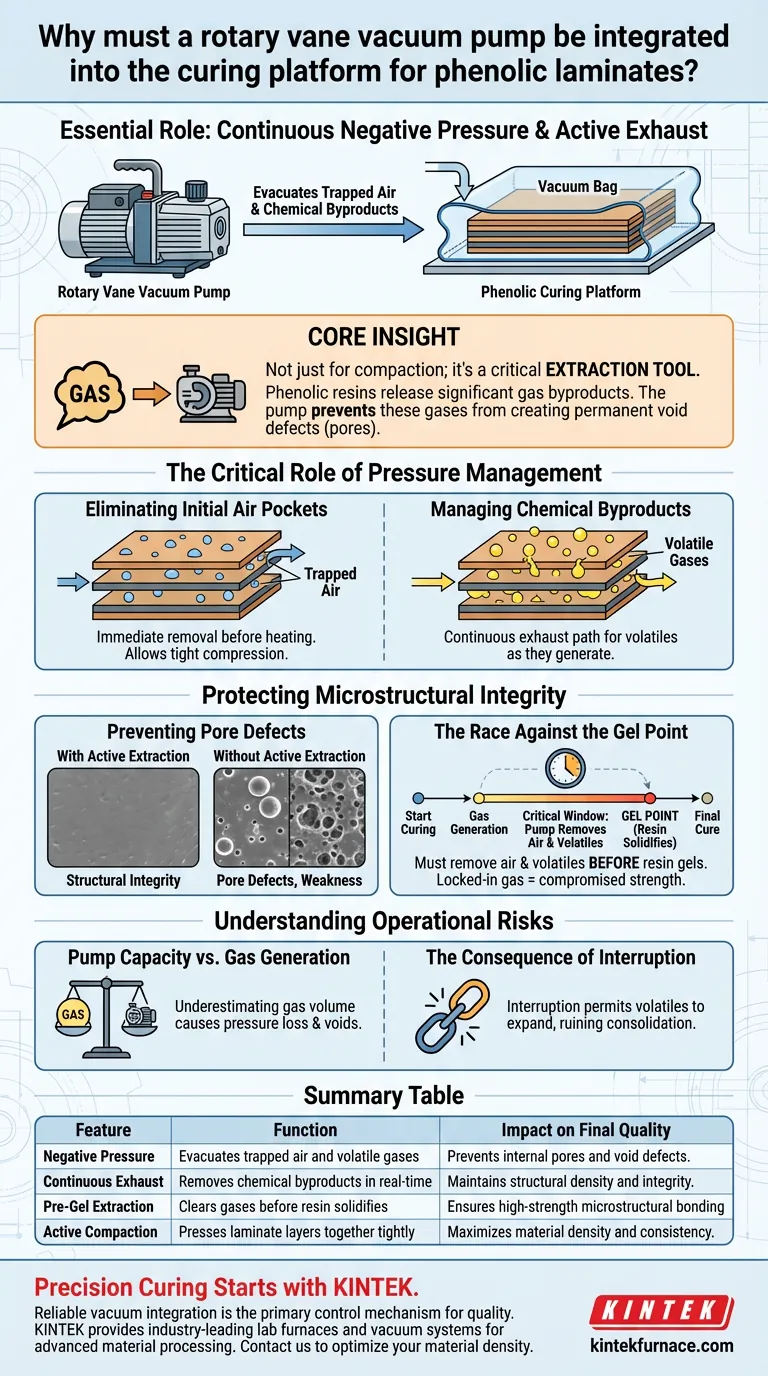

A rotary vane vacuum pump is essential for phenolic curing because it maintains continuous negative pressure to evacuate both trapped air and chemical byproducts generated during the reaction. This active exhaust system prevents volatile gases from becoming trapped within the laminate layers, ensuring the material achieves the necessary density and structural integrity.

Core Insight: Phenolic resins release significant gas byproducts during the curing process. The vacuum pump is not just for compaction; it is a critical extraction tool that prevents these gases from creating permanent void defects (pores) in the material before the resin hardens.

The Critical Role of Pressure Management

Eliminating Initial Air Pockets

Before the curing process even heats up, air is naturally trapped between the layers of the laminate.

The rotary vane pump facilitates the immediate removal of this air. This initial evacuation is crucial for allowing the layers to compress tightly against one another.

Managing Chemical Byproducts

Unlike some other resin systems, phenolic resins generate volatile gases (byproducts) as they cure.

If these gases are not removed, they build up pressure inside the vacuum bag. The pump provides a continuous exhaust path, pulling these volatiles out of the system as fast as they are generated.

Protecting Microstructural Integrity

Preventing Pore Defects

The accumulation of gases poses a direct threat to the material's microstructure.

Without active vacuum extraction, these gases form bubbles that result in pore defects. The pump ensures these volatiles are evacuated rather than becoming permanent voids in the composite.

The Race Against the Gel Point

Timing is the single most critical factor in this process.

The pump must remove air and volatiles before the resin reaches its gel point. Once the resin gels (solidifies), any remaining gas is locked into the matrix, permanently compromising the part's strength.

Understanding Operational Risks

Pump Capacity vs. Gas Generation

A common pitfall is underestimating the volume of gas phenolic resins produce.

If the pump cannot maintain negative pressure against the rate of outgassing, the vacuum level will drop. This loss of pressure immediately allows voids to nucleate and grow.

The Consequence of Interruption

Consistency is non-negotiable during the cure cycle.

Any interruption in pump operation prior to the gel point allows the vacuum bag to relax. This relaxation permits volatiles to expand instantly, ruining the consolidation of the laminate layers.

Optimizing Your Curing Strategy

To ensure high-quality phenolic laminates, align your vacuum strategy with your specific quality goals:

- If your primary focus is Structural Strength: Ensure the pump is sized to maintain high vacuum levels continuously until well past the gel point to maximize density.

- If your primary focus is Defect Elimination: Prioritize leak-checking the vacuum bag ensuring the path for gas extraction is completely unobstructed.

Reliable vacuum integration is the primary control mechanism for determining the final quality of phenolic composites.

Summary Table:

| Feature | Function in Phenolic Curing | Impact on Final Quality |

|---|---|---|

| Negative Pressure | Evacuates trapped air and volatile gases | Prevents internal pores and void defects |

| Continuous Exhaust | Removes chemical byproducts in real-time | Maintains structural density and integrity |

| Pre-Gel Extraction | Clears gases before resin solidifies | Ensures high-strength microstructural bonding |

| Active Compaction | Presses laminate layers together tightly | Maximizes material density and consistency |

Precision Curing Starts with KINTEK

Don't let volatile gases compromise the integrity of your phenolic composites. KINTEK provides industry-leading high-temperature lab furnaces and vacuum systems—including Muffle, Tube, Rotary, and CVD systems—designed to meet the rigorous demands of advanced material processing. Our expert R&D and manufacturing teams offer customizable solutions to ensure your curing platform maintains the precise vacuum levels needed for defect-free results.

Ready to optimize your material density? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Xiaodong He, Hualian Li. A Study on the Compaction Behavior and Parameter Sensitivity of Curing Phenolic Thermal Protection Material Strips. DOI: 10.3390/polym17081045

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the function of a laboratory electric blast drying oven in biomass pretreatment? Standardize Your Samples

- Why are high-purity alumina crucibles preferred over quartz crucibles at 1873 K? Ensure Precision at Extreme Heat

- What are the primary functions of a self-preheating heat exchanger? Maximize Thermal Efficiency in Double-P Tubes

- Why use sealed quartz tubes & vacuum for Mg-Zn/Mg-Cd alloy prep? Ensure Compositional Purity

- Why are Y2O3 ceramic crucibles preferred over Al2O3 for Y-DD5 superalloys? Discover the Superior Inertness of Yttria

- What is the primary function of high-purity graphite crucibles? Ensure Superior Purity in Aluminum Alloy Melting

- What function do high-strength graphite molds serve? Essential Roles in Ti-6Al-4V Vacuum Hot Pressing

- What is the purpose of using fused quartz tubes in high-temperature sealed reaction systems for alloy research?