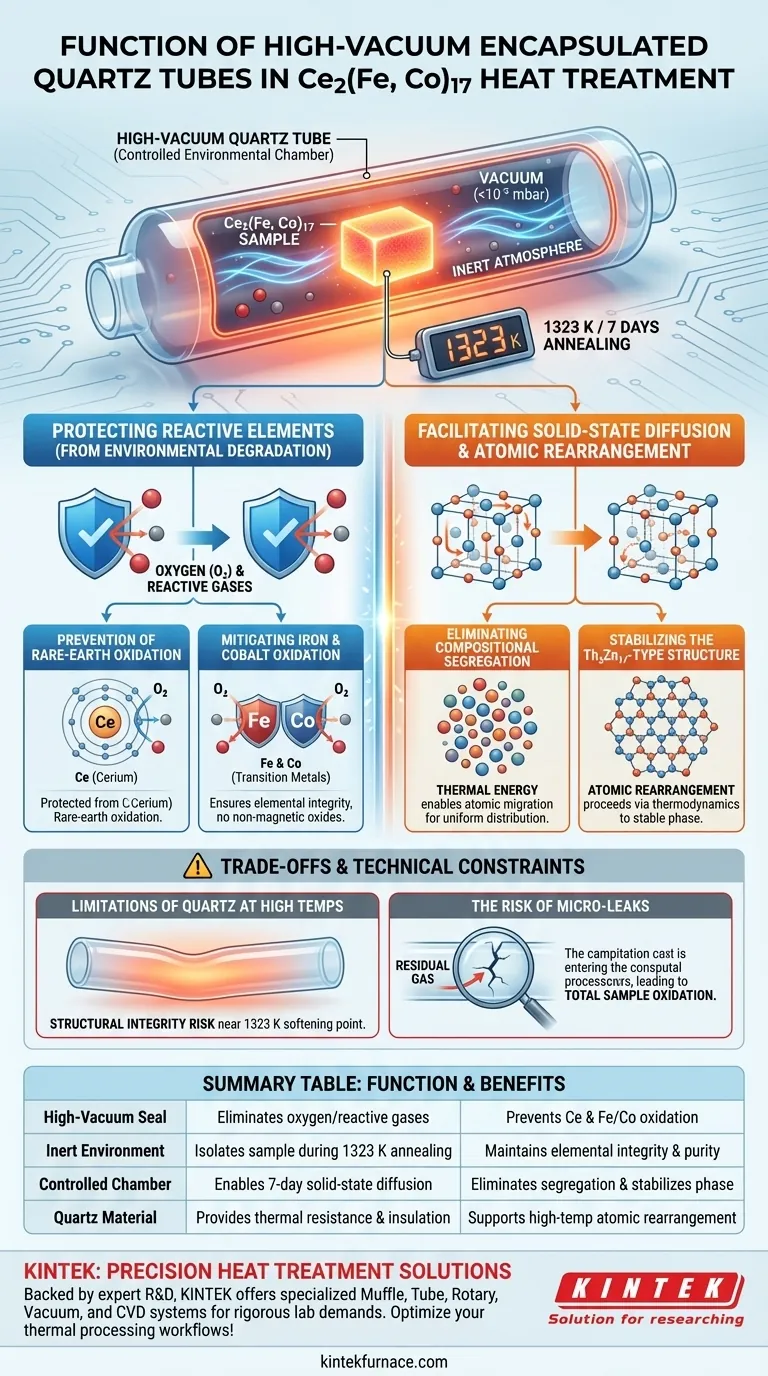

High-vacuum encapsulated quartz tubes act as a controlled environmental chamber that prevents material degradation while allowing the necessary atomic kinetics for phase stabilization in $Ce_2(Fe, Co)_{17}$. By maintaining a strictly inert atmosphere during the seven-day annealing process at 1323 K, these tubes prevent the catastrophic oxidation of rare-earth elements and iron, ensuring the formation of a homogeneous crystal structure.

The core function of high-vacuum encapsulation is to isolate the alloy from reactive gases, thereby permitting the long-duration thermal energy required to eliminate compositional segregation and lock in the desired $Th_2Zn_{17}$-type phase.

Protecting Reactive Elements from Environmental Degradation

Prevention of Rare-Earth Oxidation

Rare-earth elements like Cerium ($Ce$) are highly reactive and possess a high affinity for oxygen, especially at elevated temperatures. High-vacuum encapsulation removes oxygen from the immediate environment, ensuring that the Cerium remains within the alloy matrix rather than forming non-magnetic oxide impurities.

Mitigating Iron and Cobalt Oxidation

At the 1323 K annealing temperature, transition metals like Iron ($Fe$) and Cobalt ($Co$) are susceptible to rapid surface oxidation. The vacuum environment acts as a strictly inert protective barrier, preserving the elemental integrity of the metallic components throughout the week-long heat treatment.

Facilitating Solid-State Diffusion and Atomic Rearrangement

Eliminating Compositional Segregation

As-cast $Ce_2(Fe, Co)_{17}$ typically exhibits "segregation," where different elements are unevenly distributed throughout the material. The quartz tube allows the sample to withstand 1323 K for seven days, providing the thermal energy needed for atoms to migrate and create a uniform chemical distribution.

Stabilizing the $Th_2Zn_{17}$-Type Structure

The target $Th_2Zn_{17}$-type crystal structure is the key to the material's magnetic potential. By preventing outside chemical interference, the vacuum environment ensures that atomic rearrangement proceeds purely based on thermodynamics, resulting in a stable, high-quality crystal lattice.

Understanding the Trade-offs and Technical Constraints

Limitations of Quartz at High Temperatures

While quartz is an excellent insulator and chemically inert, it approaches its softening point near 1323 K. Users must ensure the structural integrity of the tube to prevent collapse under external atmospheric pressure during the long-term heating cycle.

The Risk of Micro-Leaks

In a seven-day process, even a microscopic failure in the vacuum seal can lead to total sample oxidation. Maintaining a high-vacuum seal is technically demanding, as any residual gas or slow leak will prioritize the formation of stable oxides over the desired metallic phase.

Strategic Considerations for Material Processing

Effective heat treatment requires a balance between environmental isolation and thermal precision to achieve the desired alloy characteristics.

- If your primary focus is phase purity: Ensure the vacuum level is as high as possible to prevent "internal oxidation," which can pin grain boundaries and inhibit proper diffusion.

- If your primary focus is structural homogeneity: Maintain the 1323 K temperature for the full duration to allow sufficient time for the elimination of as-cast segregation.

- If your primary focus is preventing tube failure: Use thick-walled quartz and ensure the encapsulation volume is minimized to reduce the impact of any potential structural stresses.

Successful synthesis of $Ce_2(Fe, Co)_{17}$ depends entirely on the quartz tube's ability to provide a pristine vacuum environment for the duration of the solid-state transformation.

Summary Table:

| Feature | Function in Heat Treatment | Benefit for Ce2(Fe, Co)17 |

|---|---|---|

| High-Vacuum Seal | Eliminates oxygen and reactive gases | Prevents rare-earth (Ce) and Fe/Co oxidation |

| Inert Environment | Isolates sample during 1323 K annealing | Maintains elemental integrity and sample purity |

| Controlled Chamber | Enables 7-day solid-state diffusion | Eliminates segregation and stabilizes crystal phase |

| Quartz Material | Provides thermal resistance and insulation | Supports high-temperature atomic rearrangement |

Precision heat treatment is the foundation of high-performance magnetic materials. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of your lab. Whether you need customizable high-temp furnaces for rare-earth processing or specialized encapsulation support, we provide the tools to ensure your materials reach their full potential. Contact KINTEK today to optimize your thermal processing workflows!

Visual Guide

References

- H. Jaballah, Lotfi Bessais. Structural, Magnetic, and Magnetocaloric Properties of Ce2(Fe, Co)17 Compounds: Tuning Magnetic Transitions and Enhancing Refrigeration Efficiency. DOI: 10.3390/ma18091958

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a drying oven during LLZTO preparation? Ensure Pure Phase Solid Electrolytes

- Is it possible to tailor high-temperature laboratory furnaces? Custom Engineering for Unique Research Needs

- What functions does the hot pressing mold perform? Key Roles in Al3Ti/Al Composite Powder Metallurgy

- What processes can a circulating water vacuum pump provide negative pressure conditions for? Essential Lab Techniques Explained

- Why is a vacuum pump system integrated into a plastic pyrolysis setup? Optimize Yield and Energy Efficiency

- What core environmental protection does an argon-protected glove box provide for sodium-ion batteries? Maximize Safety

- What precautions should be taken when using the alumina furnace tube for the first time? Ensure Safe Initial Use with Proper Conditioning

- Why are high-purity alumina tubes and crucibles preferred for high-temperature smelting? Ensure Maximum Sample Purity