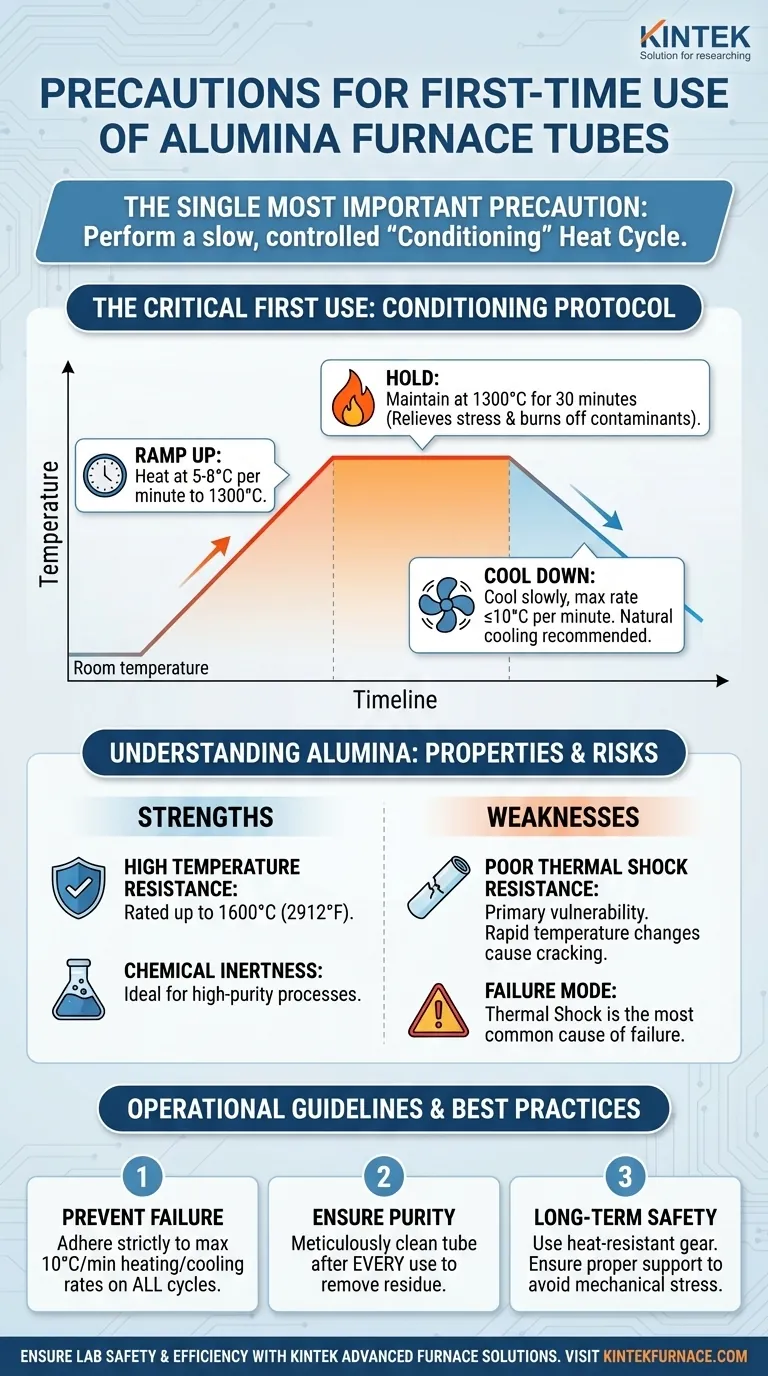

The single most important precaution when using an alumina furnace tube for the first time is to perform a slow, controlled "conditioning" heat cycle. You must preheat the tube at a rate of 5-8°C per minute up to 1300°C, hold it at that temperature for 30 minutes, and then allow it to cool slowly. This initial run is not for your experiment; its sole purpose is to prepare the ceramic for service by safely removing internal stresses and manufacturing residues.

An alumina tube is not ready for use straight out of the box. Its extreme temperature resistance comes with a critical weakness—sensitivity to rapid temperature changes. The initial conditioning cycle is a mandatory step to temper the material and prevent catastrophic failure.

The Critical First Use: Conditioning Your Tube

A new alumina tube contains residual stresses and contaminants from its manufacturing process. A deliberate, slow initial heating cycle is essential to eliminate these issues without damaging the ceramic structure.

Why Initial Heating is Non-Negotiable

During manufacturing, the ceramic develops internal stresses. It may also contain trace amounts of organic binders or surface pollutants.

Heating the tube for the first time without a proper conditioning run can cause these stresses to release unevenly, resulting in cracks. The high temperature also serves to cleanly burn off any residual contaminants.

The Prescribed Heating Protocol

Your first run should follow a specific temperature profile. The goal is to heat and cool the tube in a highly controlled manner.

Ramp the temperature up at a rate between 5°C and 8°C per minute. Once the furnace reaches 1300°C, hold it there for at least 30 minutes. This slow ramp prevents thermal shock, and the hold time ensures all stresses are relieved and contaminants are vaporized.

Controlled Cooling is Just as Important

After the 30-minute hold, you must cool the tube just as carefully. Never allow the cooling rate to exceed 10°C per minute.

Rapid cooling is a primary cause of thermal shock and will crack the tube. The safest method is to let the furnace cool down naturally while programmed to a slow ramp-down rate.

Understanding Alumina's Core Properties

To use an alumina tube effectively, you must understand its fundamental strengths and weaknesses. Its properties dictate the handling procedures required for a long service life.

Its Strength: Extreme Temperature and Chemical Resistance

Alumina (Al₂O₃) tubes are prized for their high purity (often over 99.6%) and exceptional stability at high temperatures, with many rated for continuous use up to 1600°C (2912°F).

They are also chemically inert, making them ideal for high-purity processes and experiments involving reactive materials.

Its Weakness: Poor Thermal Shock Resistance

The primary vulnerability of alumina ceramic is its poor resistance to thermal shock. This is the tendency of a material to crack when subjected to a rapid change in temperature.

When heated or cooled too quickly, different parts of the tube expand or contract at different rates, creating immense internal stress that leads to fracture. Every heating and cooling precaution is designed to mitigate this specific risk.

Understanding the Trade-offs and Risks

Operating an alumina tube involves balancing its high-performance capabilities against its inherent fragility. Understanding the risks is key to avoiding failure.

Thermal Shock: The Primary Failure Mode

Virtually all premature failures of alumina tubes are due to thermal shock. Exceeding the recommended heating or cooling rates is the most common mistake. This applies to every cycle, not just the first one.

Chemical Contamination and Attack

After use, any residual sample material left inside the tube can be a problem. In subsequent heating cycles, these residues can react with the alumina wall, creating localized stress points that weaken the tube and can lead to cracking.

Mechanical Stress

Alumina is a strong but brittle ceramic. It cannot withstand physical impact or bending forces. Ensure the tube is properly supported along its length within the furnace and handle it carefully outside the furnace to prevent mechanical fracture.

How to Apply This to Your Operations

Follow these guidelines to ensure the safety, purity, and longevity of both your equipment and your experimental results.

- If your primary focus is preventing immediate failure: Adhere strictly to the initial conditioning cycle and never exceed a heating or cooling rate of 10°C per minute on any run.

- If your primary focus is ensuring experimental purity: Always perform the initial burn-off cycle on a new tube and meticulously clean the tube after every single use to remove all sample residue.

- If your primary focus is long-term operational safety: Mandate the use of heat-resistant gloves and safety glasses for all operators and ensure everyone is trained on the furnace's proper heating and emergency shutdown procedures.

Treating your alumina tube with deliberate, controlled care is the only way to unlock its high-performance capabilities reliably and safely.

Summary Table:

| Precaution Type | Key Details |

|---|---|

| Initial Conditioning | Heat at 5-8°C/min to 1300°C, hold 30 min, cool slowly at ≤10°C/min |

| Thermal Shock Prevention | Avoid rapid temperature changes; max heating/cooling rate 10°C/min |

| Contamination Control | Burn off residues in first use; clean after each experiment |

| Mechanical Handling | Support tube fully; handle with care to prevent impact damage |

Ensure your lab's safety and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental needs, enhancing performance and reliability. Contact us today to discuss how we can support your operations!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety