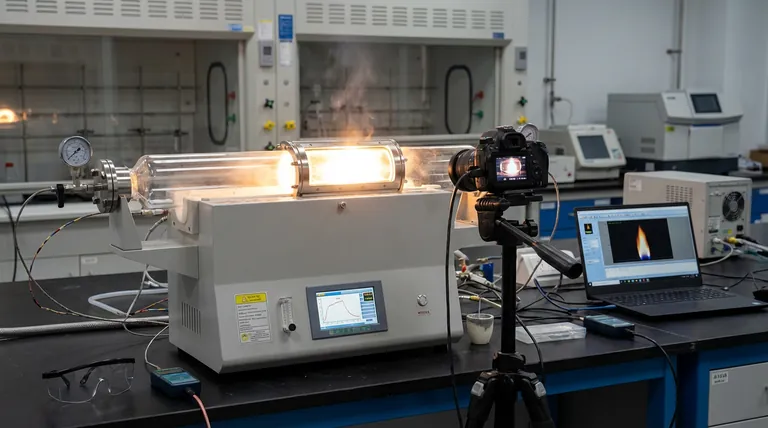

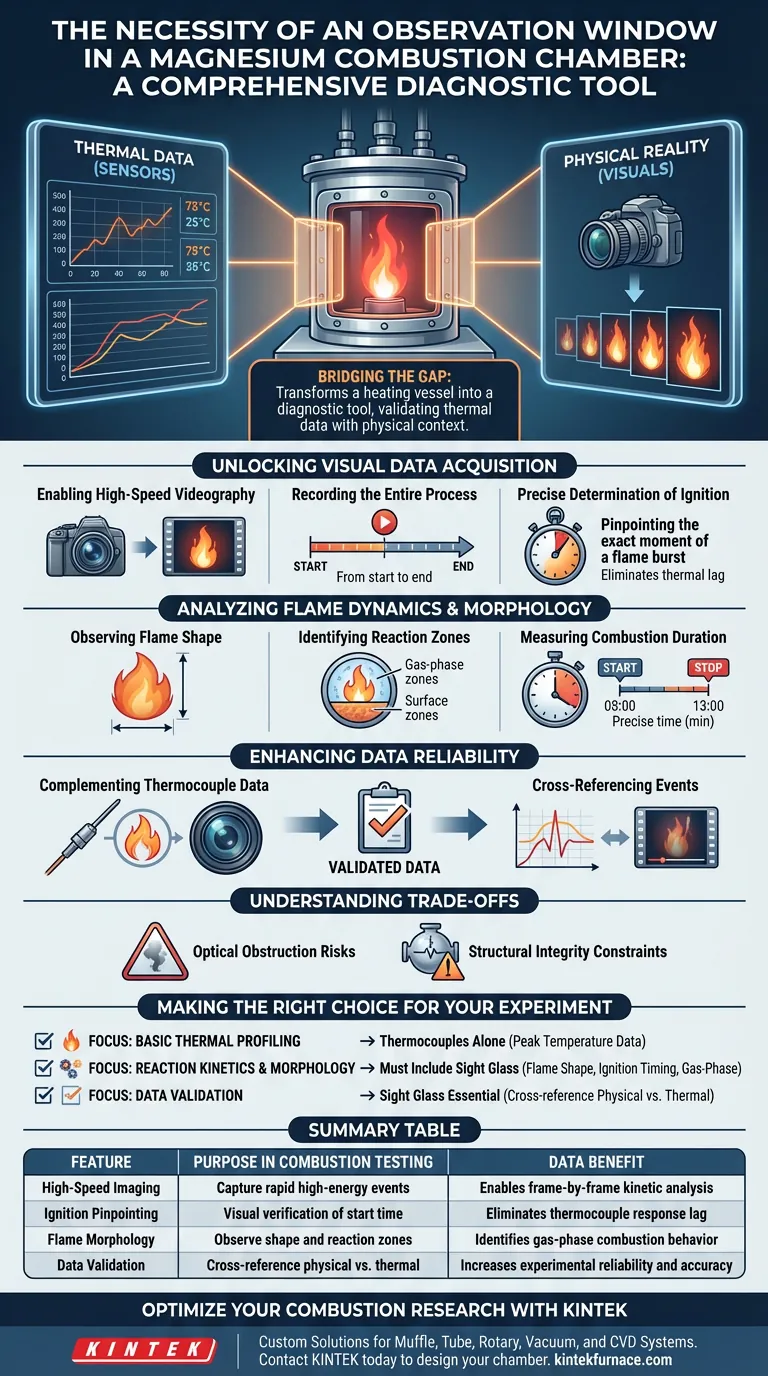

The necessity of an observation window in a magnesium combustion chamber lies in its ability to transform the apparatus from a simple heating vessel into a comprehensive diagnostic tool. By incorporating a sight glass, researchers can deploy high-speed imaging to capture the dynamic physical behavior of the combustion process, filling critical gaps that thermal sensors alone cannot address.

The integration of a sight glass bridges the gap between thermal data and physical reality. It allows for the visual verification of ignition timing and flame structure, providing the necessary context to validate temperature curves and significantly enhance the reliability of experimental analysis.

Unlocking Visual Data Acquisition

Enabling High-Speed Videography

The primary function of the sight glass is to provide optical access for high-speed cameras. Magnesium combustion is a rapid, high-energy event that occurs too quickly for the naked eye to analyze in real-time.

Recording the Entire Process

A transparent interface allows for the continuous recording of the experiment from start to finish. This creates a permanent digital record that can be slowed down and analyzed frame-by-frame after the test concludes.

Precise Determination of Ignition

Thermocouples often have a slight response lag. Visual monitoring through the sight glass allows researchers to pinpoint the exact millisecond the ignition moment occurs, independent of thermal data latency.

Analyzing Flame Dynamics and Morphology

Observing Flame Shape

One of the most critical aspects of combustion research is understanding the geometry of the reaction. The sight glass allows you to observe the flame morphology, such as whether the flame develops a spherical shape.

Identifying Reaction Zones

Visual access enables the identification of specific reaction zones. For example, researchers can visually confirm the presence and behavior of gas-phase reaction zones, which are impossible to detect with temperature sensors alone.

Measuring Combustion Duration

By reviewing the visual record, you can definitively measure the start and stop times of the burn. This provides a precise calculation of the total combustion duration, a key metric in characterizing fuel performance.

Enhancing Data Reliability

Complementing Thermocouple Data

Relying solely on temperature curves can be misleading if the sensor is displaced or the sample shifts. Visual records serve as a secondary validation stream, complementing the thermal data measured by thermocouples.

Cross-Referencing Events

When a temperature spike or anomaly appears in the data, the video footage allows you to correlate that data point with a physical event. This cross-referencing significantly enhances the overall reliability and confidence of the experimental analysis.

Understanding the Trade-offs

Optical Obstruction Risks

Magnesium combustion produces significant amounts of oxide smoke and particulate matter. A common challenge with observation windows is that they can become coated during the experiment, potentially obscuring the view of the camera partway through the test.

Structural Integrity Constraints

Introducing a glass or quartz window creates a potential weak point in the pressure vessel. The material used for the sight glass must be carefully selected to withstand the specific thermal shock and pressure generated by magnesium combustion, adding complexity to the chamber design.

Making the Right Choice for Your Experiment

If your primary focus is basic thermal profiling:

- You may rely on thermocouples alone if you only require peak temperature data and do not need to characterize the reaction mechanics.

If your primary focus is reaction kinetics and morphology:

- You must include a sight glass to capture flame shape, precise ignition timing, and gas-phase behaviors that thermal sensors cannot detect.

If your primary focus is data validation:

- A sight glass is essential to cross-reference physical events with thermal data, ensuring your conclusions are based on verified phenomena rather than sensor artifacts.

Visual access is the only way to convert abstract thermal numbers into a complete, verified narrative of the combustion event.

Summary Table:

| Feature | Purpose in Combustion Testing | Data Benefit |

|---|---|---|

| High-Speed Imaging | Capture rapid high-energy events | Enables frame-by-frame kinetic analysis |

| Ignition Pinpointing | Visual verification of start time | Eliminates thermocouple response lag |

| Flame Morphology | Observe shape and reaction zones | Identifies gas-phase combustion behavior |

| Data Validation | Cross-reference physical vs. thermal | Increases experimental reliability and accuracy |

Optimize Your Combustion Research with KINTEK

Don't let critical data vanish in a flash of light. KINTEK provides precision-engineered high-temperature solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable with robust observation windows to meet your specific research needs. Our expert R&D and manufacturing teams ensure your equipment withstands the thermal shock and pressure of intense magnesium reactions while providing the optical clarity required for high-speed diagnostics.

Ready to transform your thermal data into a complete visual narrative? Contact KINTEK today to design your custom combustion test chamber.

Visual Guide

References

- Ioan Barabulica, Ioan Mămăligă. Experimental Study on the Reaction of Magnesium in Carbon Dioxide and Nitrogen Atmosphere. DOI: 10.3390/chemengineering8020041

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How should heated crucibles be handled after an experiment? Ensure Accurate Results and Prevent Damage

- Why is a vacuum pumping system essential for DD6 alloy and ceramic shell experiments? Achieve High-Purity Results

- Why are magnesium oxide-stabilized zirconia crucibles used for melting alloys? High-Temp Stability up to 1900°C

- Why is a laboratory drying oven or heating plate necessary for Ba7Nb4MoO20? Optimize Slurry Synthesis Results

- What are the advantages of using aluminum crucibles for siloxane research? Maximize Thermal Precision and Data Accuracy

- What key functions do high-strength graphite molds perform? Optimize Al2O3/TiC Hot Press Sintering Success

- What is the role of quartz capillaries in the vacuum sealing process of sulfur? Enhance Purity and In-Situ Analysis

- Why is the use of high-vacuum pump groups critical for photothermal catalytic chamber pre-treatment?