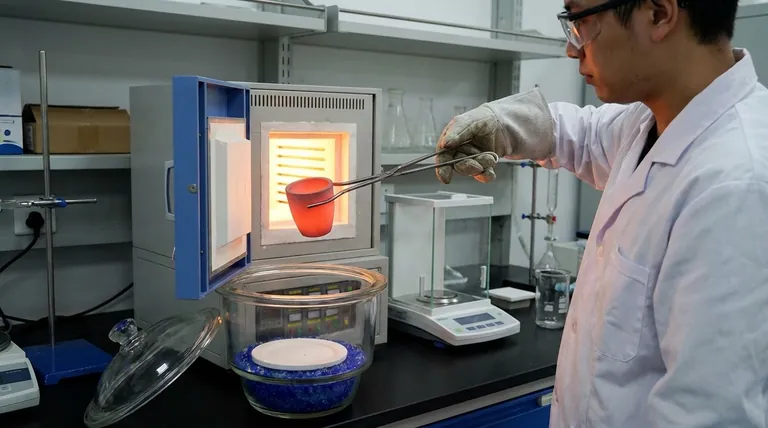

After heating, a crucible must be handled exclusively with clean crucible tongs and immediately transferred into a desiccator for cooling. This process is essential for preventing damage to the crucible and, more importantly, for protecting the integrity of your analytical sample from atmospheric moisture before you take a final, accurate weight measurement.

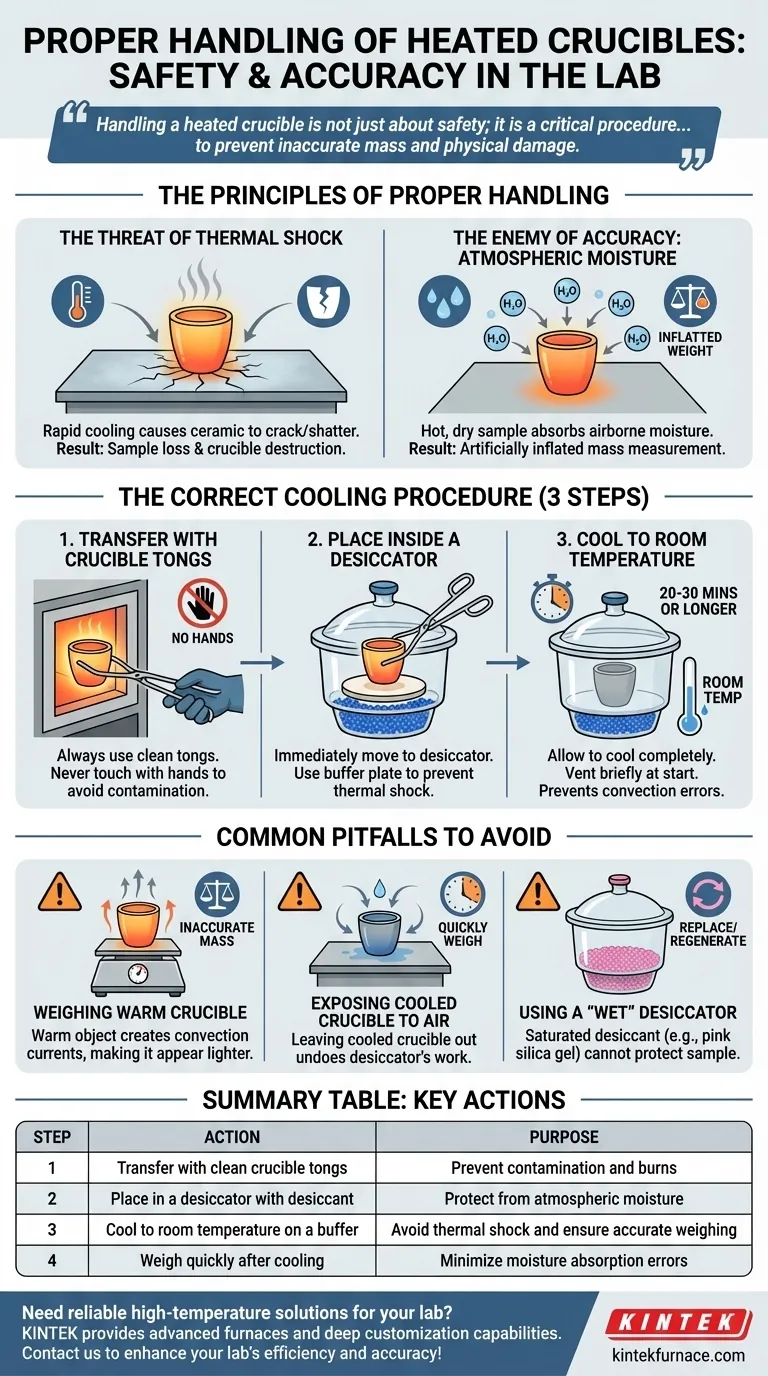

Handling a heated crucible is not just about safety; it is a critical procedure designed to prevent two major sources of error in quantitative analysis: inaccurate mass from moisture absorption and physical damage to the crucible from thermal shock.

The Principles of Proper Crucible Handling

The steps taken after a crucible is removed from a furnace or flame are dictated by the principles of chemistry and physics. Ignoring them directly impacts the quality of your results and the lifespan of your equipment.

The Threat of Thermal Shock

A crucible heated to high temperatures (often >500°C) is under immense thermal stress. Placing it directly onto a cold, hard lab bench creates a rapid, uneven temperature change.

This thermal shock can easily cause the ceramic material to crack or shatter, resulting in a total loss of your sample and the destruction of the crucible.

The Enemy of Accuracy: Atmospheric Moisture

For many experiments, especially gravimetric analysis, the goal is to measure a precise change in mass. A hot, dry sample and crucible are hygroscopic, meaning they will readily absorb moisture from the air as they cool.

This absorbed water adds mass, artificially inflating your final measurement and invalidating your results. Even a few minutes of exposure to open air can introduce significant error.

The Correct Cooling Procedure

To mitigate these risks, a specific, controlled procedure is required. The key is to move the crucible from a hot environment to a dry, protected environment for gradual cooling.

Step 1: Transfer with Crucible Tongs

Always use clean crucible tongs to handle a hot crucible. Never touch it with your hands, even with heat-resistant gloves, as oils and residues can transfer to the crucible surface and affect its mass. Grip the crucible firmly but gently to avoid dropping it.

Step 2: Place Inside a Desiccator

Immediately move the crucible from the heat source into a desiccator. A desiccator is a sealed container that contains a drying agent (a desiccant) like silica gel or anhydrous calcium chloride.

Inside the desiccator, place the crucible on a ceramic plate or a wire gauze pad. This buffer material prevents direct contact with the colder, heavier base plate, providing a final layer of protection against thermal shock.

Step 3: Cool to Room Temperature

Seal the desiccator lid. It is critical to leave a small opening for the first few minutes or to vent it periodically. As the hot crucible heats the air inside, the pressure will increase, which can cause the lid to pop off or prevent a proper seal from forming later.

Allow the crucible to cool completely to room temperature. This can take 20-30 minutes or longer, depending on the initial temperature.

Common Pitfalls to Avoid

Mistakes in this final stage are common and can ruin an otherwise perfectly executed experiment. Understanding them is key to generating reliable data.

Weighing a Warm Crucible

Never weigh a crucible while it is still warm. A warm object heats the air around it, creating convection currents. These air currents create an upward buoyant force on the balance pan, making the measured mass appear lighter than it actually is. This is a significant and frequent source of analytical error.

Exposing the Cooled Crucible to Air

Once the crucible is cool, it should be weighed as quickly as possible. Leaving a cool, dry crucible on the lab bench for even a few minutes allows it to begin absorbing atmospheric moisture again, undoing the work of the desiccator.

Using a "Wet" Desiccator

The desiccant at the bottom of the desiccator must be active. If the indicating silica gel has changed color (e.g., from blue to pink), it is saturated with water and can no longer protect your sample. Regenerate or replace the desiccant regularly.

Making the Right Choice for Your Goal

Your handling procedure directly supports the goal of your experiment.

- If your primary focus is quantitative accuracy: Always cool the crucible to room temperature inside a functional desiccator before weighing to eliminate errors from moisture and convection.

- If your primary focus is safety and equipment longevity: Use proper tongs and place hot crucibles on a ceramic or wire buffer to prevent burns and thermal shock cracking.

Mastering this simple procedure is fundamental to achieving both reliable analytical results and maintaining a safe, efficient laboratory environment.

Summary Table:

| Step | Action | Purpose |

|---|---|---|

| 1 | Transfer with clean crucible tongs | Prevent contamination and burns |

| 2 | Place in a desiccator with desiccant | Protect from atmospheric moisture |

| 3 | Cool to room temperature on a buffer | Avoid thermal shock and ensure accurate weighing |

| 4 | Weigh quickly after cooling | Minimize moisture absorption errors |

Need reliable high-temperature solutions for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental needs. Contact us today to enhance your lab's efficiency and accuracy!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production