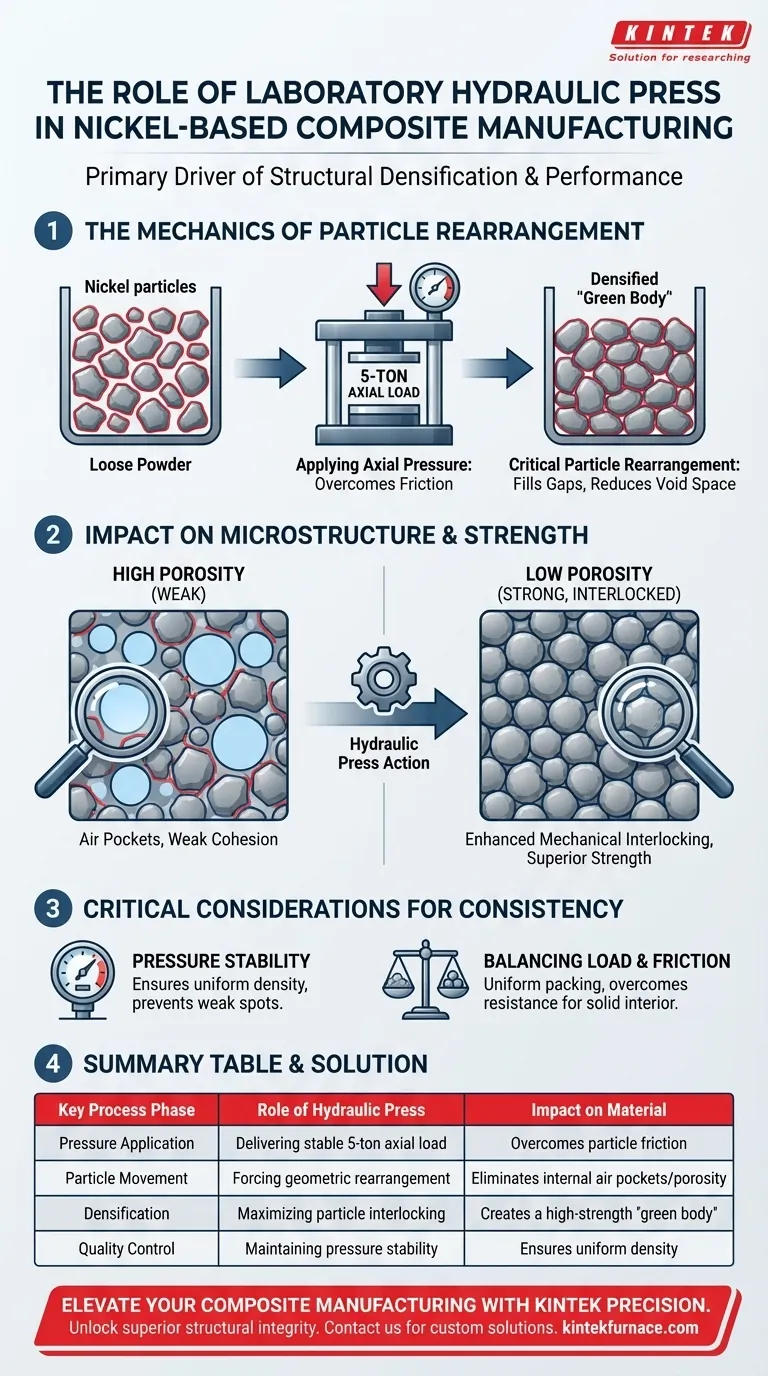

The laboratory hydraulic press acts as the primary driver of structural densification in nickel-based composites. It applies precise axial pressure—often reaching loads around 5 tons—to maintain stability during the forming process. By forcing powder particles to overcome friction and rearrange, the press directly dictates the density and mechanical integrity of the component.

High-performance composites require the elimination of microscopic voids to achieve structural integrity. The hydraulic press solves this by applying a controlled, stable load that minimizes internal porosity and maximizes particle interlocking, ensuring the formed material possesses the necessary strength.

The Mechanics of Particle Rearrangement

Applying Axial Pressure

The core function of the press is the delivery of significant axial pressure, such as a 5-ton load.

This external force is required to counteract the natural resistance of the powder. Without sufficient load, the particles remain loosely packed, leading to weak structural cohesion.

Overcoming Inter-Particle Friction

For a composite to form correctly, the powder particles must move past one another.

The pressure from the press forces these particles to overcome friction. This allows them to slide into closer proximity, filling gaps that would otherwise remain as empty space.

Critical Particle Rearrangement

Once friction is overcome, the particles undergo rearrangement.

They shift from a chaotic, loose distribution into a tightly packed configuration. This geometric reordering is the physical mechanism that transforms loose powder into a solid shape.

Impact on Microstructure and Strength

Reducing Internal Porosity

The most significant outcome of this process is a drastic reduction in internal porosity.

By forcing particles into tighter arrangements, the press eliminates air pockets within the material. Lower porosity is directly correlated with higher performance in nickel-based components.

Enhancing Mechanical Interlocking

As particles are pressed together, they mechanically lock into place.

This mechanical interlocking creates a cohesive bond between the particles. It ensures the "green body" (the formed object before final processing) has sufficient structural strength to be handled without crumbling.

Increasing Final Product Strength

The ultimate result of reduced porosity and improved interlocking is superior final product strength.

A well-pressed component will exhibit better mechanical properties. The stability of the pressure applied during this stage sets the baseline for the component's performance.

Critical Considerations for Consistency

The Necessity of Pressure Stability

The reference emphasizes the need to maintain stable pressure during the forming process.

If the hydraulic press cannot deliver a consistent load, particle rearrangement will be uneven. This leads to density gradients, where some parts of the component are strong and dense while others remain porous and weak.

Balancing Load and Friction

Applying pressure is a balancing act between the applied load and the material's internal friction.

The load must be high enough to force movement but controlled enough to ensure uniform packing. Failure to overcome friction results in a component that looks solid on the outside but retains a porous, weak interior.

Making the Right Choice for Your Goal

To maximize the quality of your nickel-based composites, you must focus on the specific outcomes of the pressing phase.

- If your primary focus is Density: Ensure your press can deliver sufficient axial load (e.g., 5 tons) to force complete particle rearrangement and eliminate porosity.

- If your primary focus is Structural Integrity: Prioritize the stability of the pressure maintenance to guarantee uniform mechanical interlocking throughout the component.

The hydraulic press is not just a shaping tool; it is the instrument that establishes the fundamental material properties of your composite.

Summary Table:

| Key Process Phase | Role of Hydraulic Press | Impact on Material |

|---|---|---|

| Pressure Application | Delivering stable 5-ton axial load | Overcomes particle friction |

| Particle Movement | Forcing geometric rearrangement | Eliminates internal air pockets/porosity |

| Densification | Maximizing particle interlocking | Creates a high-strength "green body" |

| Quality Control | Maintaining pressure stability | Ensures uniform density and prevents weak spots |

Elevate Your Composite Manufacturing with KINTEK Precision

Unlock superior structural integrity for your nickel-based components with KINTEK’s advanced laboratory hydraulic presses. Backed by expert R&D and world-class manufacturing, we provide the precise, stable pressure control essential for eliminating porosity and maximizing mechanical interlocking in your materials.

Whether you require specialized Muffle, Tube, Rotary, Vacuum, or CVD systems, our laboratory high-temp furnaces and high-performance presses are fully customizable to meet your unique research and production needs.

Ready to optimize your material density and strength? Contact us today to discuss your custom solution!

Visual Guide

References

- Hermansyah Aziz, Ibrahim k. salman. Effect of Adding Nano Carbon on Density, Porosity, and Water Absorption of Nickel by Powder Metallurgy. DOI: 10.55810/2313-0083.1102

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What type of pump is used in water circulating vacuum pumps and how is it installed? Discover Robust Fluid-Based Vacuum Solutions

- What are the key properties of alumina ceramic furnace tubes? Discover Their High-Temp and Chemical Resistance

- What are the advantages of nickel crucibles for KOH activation? Ensure High Purity & Thermal Stability up to 700°C

- What are the technical considerations for using alumina crucibles? Optimize High-Entropy Alloy Purity & Microstructure

- What is the necessity of a cylindrical condenser in a microwave-assisted metal reduction system? Key Protection Insights

- How does the impeller in a water circulating vacuum pump function to create a vacuum? Discover the Liquid Piston Mechanism

- How do high-precision mass flow controllers (MFC) aid iron oxide reduction studies? Get Accurate Kinetic Data

- Is it possible to tailor high-temperature laboratory furnaces? Custom Engineering for Unique Research Needs