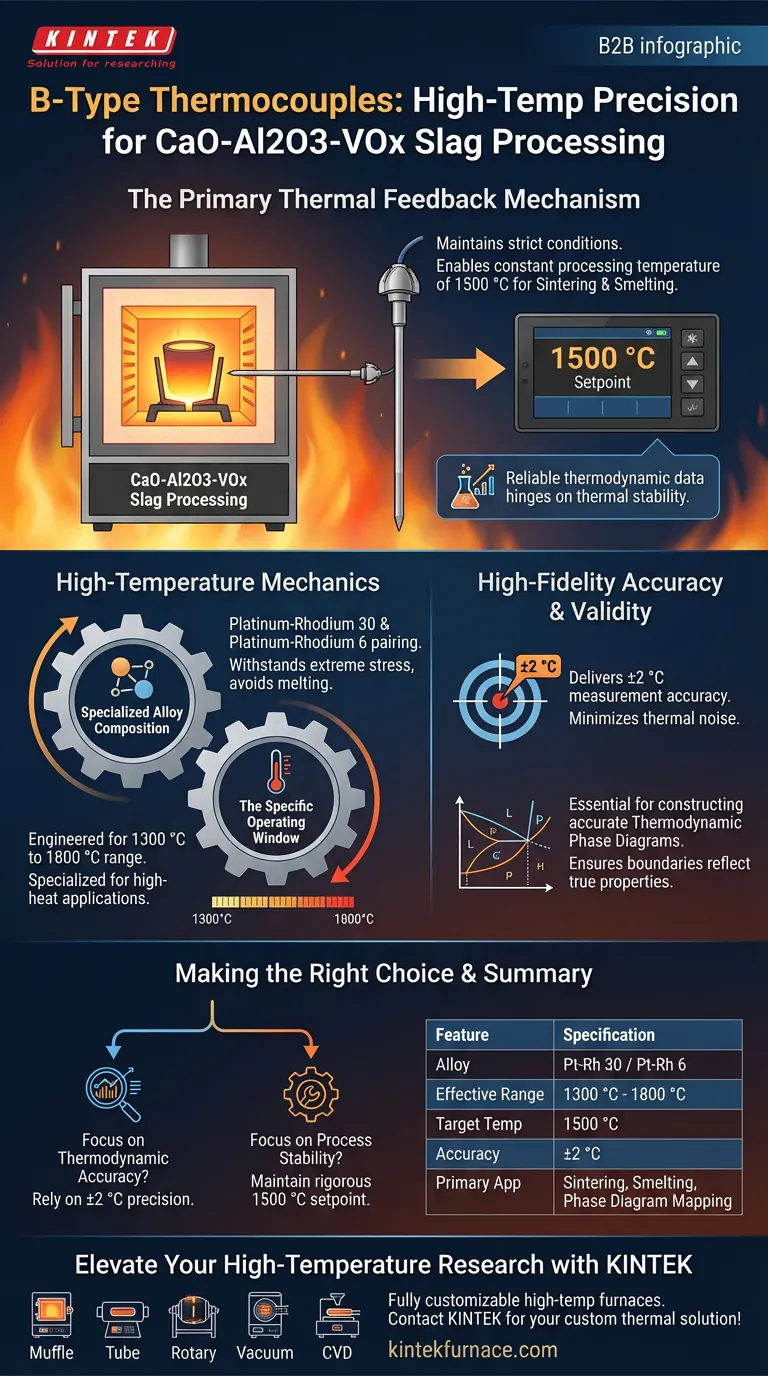

B-type thermocouples function as the primary thermal feedback mechanism for maintaining the strict environmental conditions required during the processing of CaO-Al2O3-VOx slag. Composed of Platinum-Rhodium alloys, these sensors deliver high-precision measurements within the extreme 1300 °C to 1800 °C range, enabling the system to hold a constant processing temperature of 1500 °C.

The reliability of CaO-Al2O3-VOx thermodynamic data hinges entirely on thermal stability; B-type thermocouples provide the ±2 °C accuracy necessary to validate phase diagrams during sintering and smelting.

The Mechanics of High-Temperature Precision

To understand why B-type thermocouples are essential for this specific slag processing, one must look at their material composition and operating range. Standard sensors would degrade or drift under these conditions, but the B-type is engineered specifically for stability.

Specialized Alloy Composition

The B-type thermocouple utilizes a specific pairing of Platinum-Rhodium 30 and Platinum-Rhodium 6.

This specific alloy combination is chosen for its ability to withstand extreme thermal stress without melting or losing calibration. It is the physical foundation that allows for consistent measurement in high-heat metallurgical environments.

The 1500 °C Target

Processing CaO-Al2O3-VOx slag requires distinct stages of sintering and smelting.

To ensure these processes occur correctly, the furnace must maintain a constant temperature of 1500 °C. The B-type thermocouple provides the real-time data required to regulate the heat source and lock in this specific setpoint.

High-Fidelity Accuracy

In scientific processing, an approximate temperature is insufficient; the data must be exact.

B-type thermocouples offer a measurement accuracy of ±2 °C. This tight tolerance minimizes thermal noise, ensuring that the observed physical changes in the slag are a result of chemistry, not temperature fluctuation.

The Role in Experimental Validity

Beyond simple process control, the choice of thermocouple dictates the scientific value of the results. The ultimate goal of these experiments is often the construction of accurate thermodynamic phase diagrams.

Ensuring Diagram Accuracy

Phase diagrams map the stability of different chemical phases at various temperatures.

If the temperature input is inaccurate, the resulting phase boundaries will be incorrect. By guaranteeing precise thermal control, the B-type thermocouple ensures the resulting diagrams truly reflect the thermodynamic properties of the CaO-Al2O3-VOx system.

Operational Constraints and Considerations

While B-type thermocouples are superior for this application, it is important to understand their operational boundaries to ensure data integrity.

The Specific Operating Window

These sensors are designed for a specific high-temperature window of 1300 °C to 1800 °C.

Attempting to use them for precision measurement significantly below this range may result in reduced accuracy or non-linear output. They are specialized tools intended strictly for high-heat applications like slag smelting.

Making the Right Choice for Your Goal

Selecting the correct thermal sensor is about matching the device's capabilities to your specific processing objectives.

- If your primary focus is Thermodynamic Accuracy: Rely on the B-type thermocouple to provide the ±2 °C precision required to construct valid phase diagrams.

- If your primary focus is Process Stability: Utilize this sensor to maintain the rigorous 1500 °C setpoint needed for consistent sintering and smelting of oxide slags.

Precision in measurement is the prerequisite for precision in science.

Summary Table:

| Feature | B-Type Thermocouple Specification |

|---|---|

| Alloy Composition | Platinum-Rhodium 30 / Platinum-Rhodium 6 |

| Effective Range | 1300 °C to 1800 °C |

| Target Processing Temperature | 1500 °C |

| Measurement Accuracy | ±2 °C |

| Primary Application | Sintering, Smelting, and Phase Diagram Mapping |

Elevate Your High-Temperature Research with KINTEK

Precise thermal control is the backbone of metallurgical accuracy. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temp furnaces—all fully customizable to your unique processing needs. Whether you are constructing complex thermodynamic phase diagrams or perfecting slag smelting, our equipment provides the stability and precision your data demands.

Ready to optimize your lab's performance? Contact KINTEK today to discuss your custom thermal solution!

Visual Guide

References

- Chengjun Liu, Guojie Huo. The Phase Diagram of a CaO-Al2O3-VOx Slag System under Argon Atmosphere at 1500 °C. DOI: 10.3390/met14010108

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the maximum vacuum capacity of the water circulating vacuum pump? Uncover Its Ideal Lab Applications

- What role does a laboratory hydraulic press play in manufacturing nickel composites? Achieving Maximum Density

- What functions does a high-density graphite crucible perform? More Than a Container for Copper Refining

- What are the properties and uses of ceramic tubes? Unlock High-Temp, Insulating Solutions

- Are customization options available for alumina ceramic furnace tubes? Tailor Them for Your Lab's Needs

- What is the function of ceramic balls within a box furnace? Improve Coke Graphitization & System Safety

- What are the specific functions of high-purity graphite molds in SPS? Optimize Your Sintering Process

- What is the role of quartz capillaries in the vacuum sealing process of sulfur? Enhance Purity and In-Situ Analysis