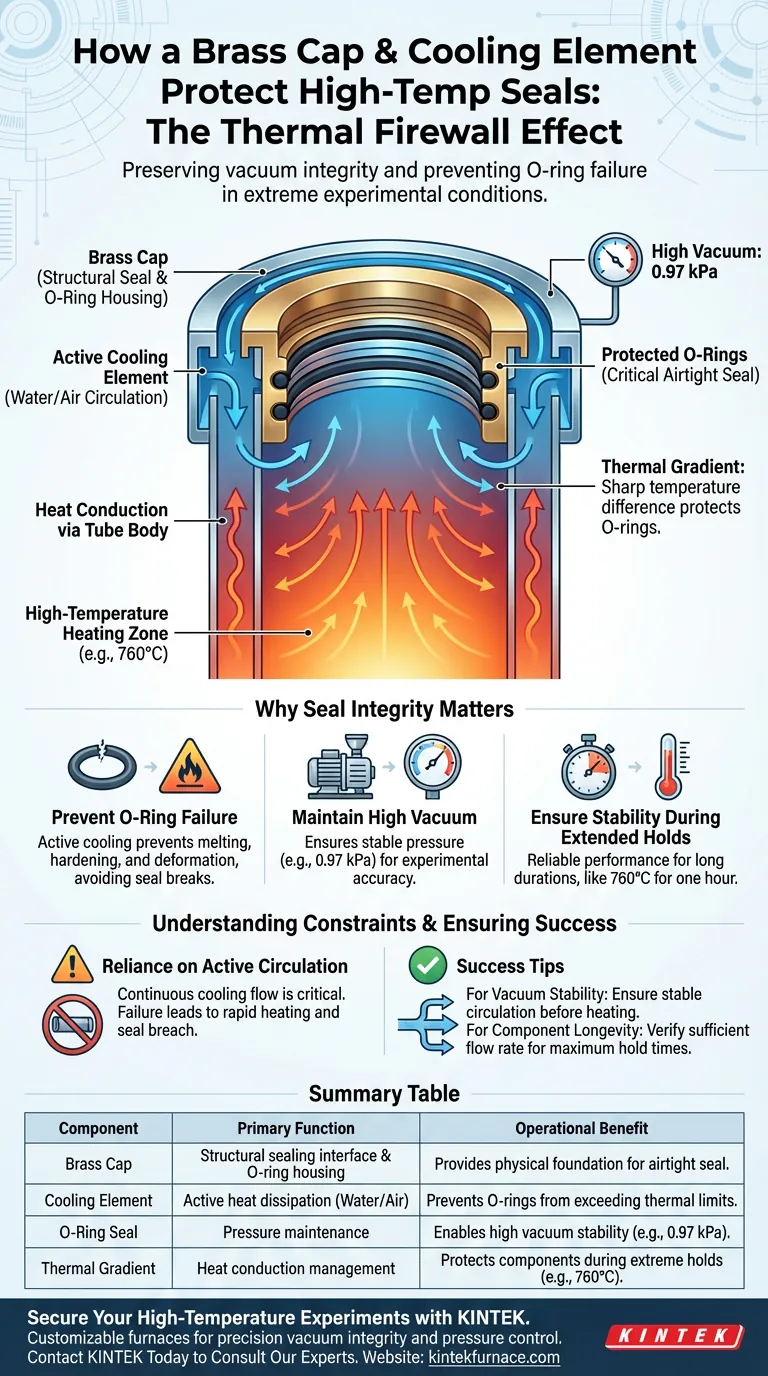

The primary function of the brass cap and cooling element is to act as a thermal firewall that preserves the vacuum seal. While the brass cap physically closes the top of the furnace tube, the integrated cooling element circulates water or air to dissipate heat conducted up from the furnace body. This active cooling prevents the O-rings from exceeding their thermal limits, ensuring the system maintains a high vacuum and preventing gas leaks during high-temperature experiments.

The collaboration between the brass cap and cooling element is effectively a thermal management strategy. By neutralizing heat conduction at the tube's opening, this assembly protects vulnerable O-rings, ensuring vacuum integrity and pressure control even when the furnace core operates at extreme temperatures like 760°C.

The Mechanics of Thermal Protection

The Role of the Brass Cap

The brass cap serves as the foundational sealing assembly at the top of the furnace tube.

It provides the necessary structural interface to close the system. More importantly, it acts as the housing for the sensitive O-rings that create the actual airtight seal.

Active Heat Dissipation

In high-temperature operations, heat travels from the heating zone up the tube body via conduction.

To counter this, the cap integrates cooling elements that facilitate water or air circulation. These elements absorb and carry away thermal energy before it can saturate the brass cap.

Creating a Thermal Gradient

This setup establishes a sharp temperature difference between the furnace body and the seal.

While the experiment runs at high temperatures, the cap remains cool enough to touch. This prevents the heat from compromising the mechanical properties of the sealing components.

Why Seal Integrity Matters

Preventing O-Ring Failure

O-rings are generally the weak point in a high-temperature assembly.

Without the active cooling provided by the cap's elements, conducted heat would degrade the O-rings. This leads to melting, hardening, or deformation, which inevitably breaks the seal.

Maintaining High Vacuum

For experimental accuracy, maintaining specific pressure environments is critical.

A properly cooled brass cap allows the system to hold a high vacuum, such as 0.97 kPa, throughout the process. This stability is essential for preventing atmospheric contamination or pressure fluctuations.

Ensuring Stability During Extended Holds

Experimental protocols often require maintaining heat for long durations, such as 760°C for one hour.

The cooling element ensures that the seal does not degrade over time. This reliability prevents gas leaks that would otherwise ruin the experiment midway through the process.

Understanding the Constraints

Reliance on Active Circulation

The system's integrity is entirely dependent on the continuous flow of the cooling medium (water or air).

If the circulation pump fails or a line becomes blocked, the protection vanishes. The brass cap will heat up rapidly, likely resulting in immediate seal failure.

Thermal Conductivity Management

While brass is an effective material for the cap, it is also conductive.

The cooling element must be efficient enough to overcome the rate at which the brass absorbs heat from the tube. If the furnace temperature exceeds the cooling capacity, the "cold zone" at the top may still become too hot for standard O-rings.

Ensuring Experimental Success

To maximize the reliability of your high-temperature seals, consider your specific operational parameters:

- If your primary focus is Vacuum Stability: Ensure your cooling circulation is active and stable before the furnace begins its heating ramp to maintain the 0.97 kPa target.

- If your primary focus is Component Longevity: Verify that the cooling medium flow rate is sufficient to keep the brass cap cool to the touch during the maximum hold time (e.g., 760°C for one hour).

The synergy between the brass cap and the cooling element is the linchpin of pressure control, turning a volatile high-heat environment into a stable experimental chamber.

Summary Table:

| Component | Primary Function | Operational Benefit |

|---|---|---|

| Brass Cap | Structural sealing interface & O-ring housing | Provides the physical foundation for an airtight seal. |

| Cooling Element | Active heat dissipation (Water/Air) | Prevents O-rings from exceeding thermal limits. |

| O-Ring Seal | Pressure maintenance | Enables high vacuum stability (e.g., 0.97 kPa). |

| Thermal Gradient | Heat conduction management | Protects components during extreme holds (e.g., 760°C). |

Secure Your High-Temperature Experiments with KINTEK

Don't let seal failure compromise your critical research. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of high-performance lab equipment, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Our furnaces are fully customizable to your unique thermal management needs, ensuring precision vacuum integrity and pressure control for every application.

Ready to upgrade your lab's thermal protection? Contact KINTEK Today to Consult Our Experts

Visual Guide

References

- Aleksandar M. Mitrašinović, Milinko Radosavljević. Modeling of Impurities Evaporation Reaction Order in Aluminum Alloys by the Parametric Fitting of the Logistic Function. DOI: 10.3390/ma17030728

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

People Also Ask

- What is the main purpose of BN coating on graphite in Ti-6Al-4V hot pressing? Ensure Purity & Easy Release

- Why is a vacuum suction system required during the exhaust stage of rice straw-based charcoal carbonization?

- How do digital mass flow controllers (MFC) maintain a constant smelting atmosphere? Ensure Precise Gas Control

- Why are high-purity graphite crucibles with lids used for ilmenite reduction? Control Your Micro-Reducing Atmosphere

- What role do substrate heaters play in Ga2O3:Er thin films? Unlock Crystalline Beta-Phase Transitions

- What is the function of glass tubes in molten-core thermal drawing? Precision Shaping and Chemical Isolation

- Why is vacuum sealing in high-purity quartz tubes necessary for the synthesis of FexTaSe2? Master Crystal Growth

- What are the advantages of using a quartz glass reactor? Superior Visibility & Purity in Molten Salt Experiments