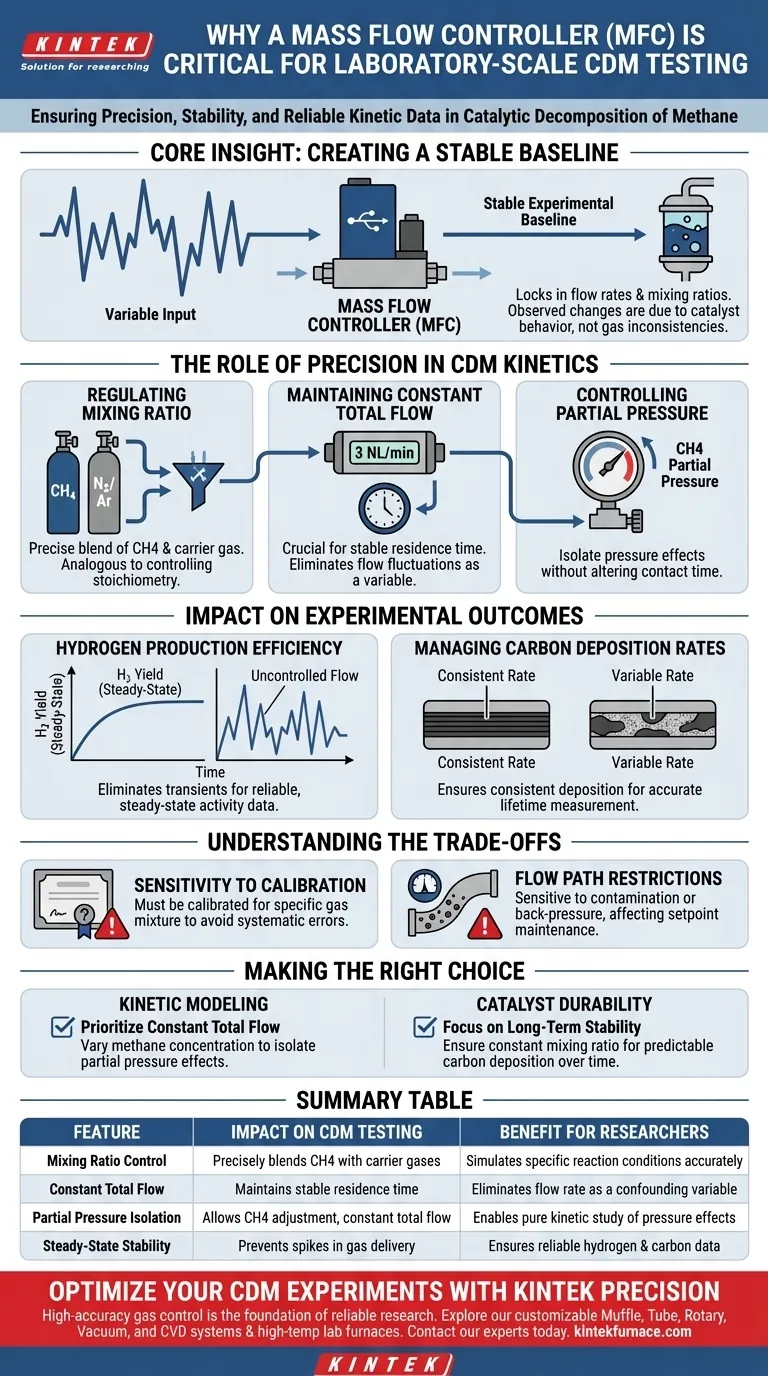

In laboratory-scale Catalytic Decomposition of Methane (CDM), a Mass Flow Controller (MFC) is the definitive tool for establishing a controlled reaction environment. It serves the fundamental function of precisely regulating the mixing ratio of methane and inert dilution gases, such as nitrogen or argon, to ensure the reaction proceeds under a strictly constant total flow rate.

Core Insight: The MFC transforms variable gas inputs into a stable experimental baseline. By locking in flow rates and mixing ratios, it ensures that any observed changes in hydrogen yield or carbon formation are caused by the catalyst's behavior, not by inconsistencies in gas delivery.

The Role of Precision in CDM Kinetics

To understand the necessity of an MFC, one must look beyond simple gas delivery. The device allows researchers to isolate specific variables within the kinetic equation.

Regulating the Mixing Ratio

CDM testing rarely uses pure methane in isolation. It requires a precise blend of methane and a carrier gas to simulate specific reaction conditions.

The MFC manages the exact proportion of methane relative to dilution gases like nitrogen or argon. This capability is analogous to controlling stoichiometry in chemical synthesis, where the ratio of reactants dictates the final product's quality.

Maintaining Constant Total Flow

A valid kinetic study requires a stable baseline. The primary function of the MFC is to maintain a constant total flow rate—for instance, 3 NL/min—regardless of the methane concentration.

If the total flow fluctuates, the residence time of the gas over the catalyst changes. This introduces a confounding variable that renders kinetic data unreliable.

Controlling Partial Pressure

By keeping the total flow constant while adjusting the methane ratio, researchers can manipulate the methane partial pressure.

This isolation is critical. It allows you to investigate specifically how different partial pressures influence hydrogen production efficiency without altering the contact time between the gas and the catalyst.

Impact on Experimental Outcomes

The physical output of CDM is hydrogen gas and solid carbon. The quality of data regarding both outputs relies heavily on flow stability.

Hydrogen Production Efficiency

Reliable kinetic data depends on steady-state conditions. Fluctuations in gas flow can cause temporary spikes or drops in conversion rates.

An MFC eliminates these transients. It ensures that the hydrogen production data you record reflects the true steady-state activity of the catalyst.

Managing Carbon Deposition Rates

CDM produces solid carbon as a byproduct, which eventually deactivates the catalyst. The rate at which this carbon deposits is directly linked to the stability of the gas environment.

Just as precise flow control affects crystal growth in other synthesis processes, the MFC ensures a consistent carbon deposition rate. This consistency is vital for accurately measuring catalyst lifetime and deactivation mechanisms.

Understanding the Trade-offs

While an MFC is necessary for high-quality data, relying on high-precision instrumentation introduces specific challenges that must be managed.

Sensitivity to Calibration

An MFC is only as good as its calibration. If the device drifts or is calibrated for a different gas mixture than the one being used, the "precise" data it outputs will be systematically incorrect.

Flow Path Restrictions

MFCs can be sensitive to particulate contamination or pressure drops. In a setup involving carbon production (CDM), back-pressure or downstream blockages can affect the controller's ability to maintain the setpoint, potentially masking issues within the reactor.

Making the Right Choice for Your Experiment

The specific settings of your Mass Flow Controller should be dictated by the primary goal of your CDM study.

- If your primary focus is Kinetic Modeling: Prioritize maintaining a constant total flow rate (e.g., 3 NL/min) while varying methane concentration to isolate partial pressure effects.

- If your primary focus is Catalyst Durability: Focus on long-term stability of the mixing ratio to ensure carbon deposition occurs at a constant, predictable rate throughout the catalyst's lifecycle.

The MFC is not just a valve; it is the control variable that validates the integrity of your entire dataset.

Summary Table:

| Feature | Impact on CDM Testing | Benefit for Researchers |

|---|---|---|

| Mixing Ratio Control | Precisely blends CH4 with carrier gases (N2/Ar). | Simulates specific reaction conditions accurately. |

| Constant Total Flow | Maintains stable residence time over the catalyst. | Eliminates flow rate as a confounding variable. |

| Partial Pressure Isolation | Allows CH4 adjustment without changing total flow. | Enables pure kinetic study of pressure effects. |

| Steady-State Stability | Prevents spikes in gas delivery. | Ensures reliable hydrogen yield and carbon data. |

Optimize Your CDM Experiments with KINTEK Precision

High-accuracy gas control is the foundation of reliable Catalytic Decomposition of Methane research. At KINTEK, we understand that experimental integrity relies on the quality of your equipment. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-temperature lab furnaces—all fully customizable to integrate seamlessly with your Mass Flow Controllers and specific testing needs.

Ready to elevate your lab's performance? Contact our experts today to discuss your custom furnace solution and ensure your catalyst data is always precise and reproducible.

Visual Guide

References

- Roger Khalil, Øyvind Skreiberg. Catalytic Methane Decomposition for the Simultaneous Production of Hydrogen and Low-Reactivity Biocarbon for the Metallurgic Industry. DOI: 10.3390/en18030558

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Ultra High Vacuum CF Observation Window Flange with High Borosilicate Glass Sight Glass

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the necessity of using an alumina closed-end tube? Protect Your Aluminum Alloy Melting Process

- What is the technical objective of using vacuum-sealed quartz capsules for Co-Ti-V alloy homogenization? Safeguard Chemical Integrity

- What is the function of a high-precision mass flow controller (MFC) in CdS nanobelt vapor deposition?

- What is the function of a vacuum ampoule during the synthesis of ZnGeP2? Ensure Purity and Chemical Stability

- What are the functions of Silica Quartz Tubes and quartz glass wool in RDF pyrolysis? Enhancing Experimental Accuracy

- How does the hardness of alumina ceramics compare to other materials? Discover Its Superior Wear Resistance

- How does insulation affect laboratory furnace design? Optimize Thermal Performance and Safety

- What are the advantages of using aluminum crucibles for siloxane research? Maximize Thermal Precision and Data Accuracy