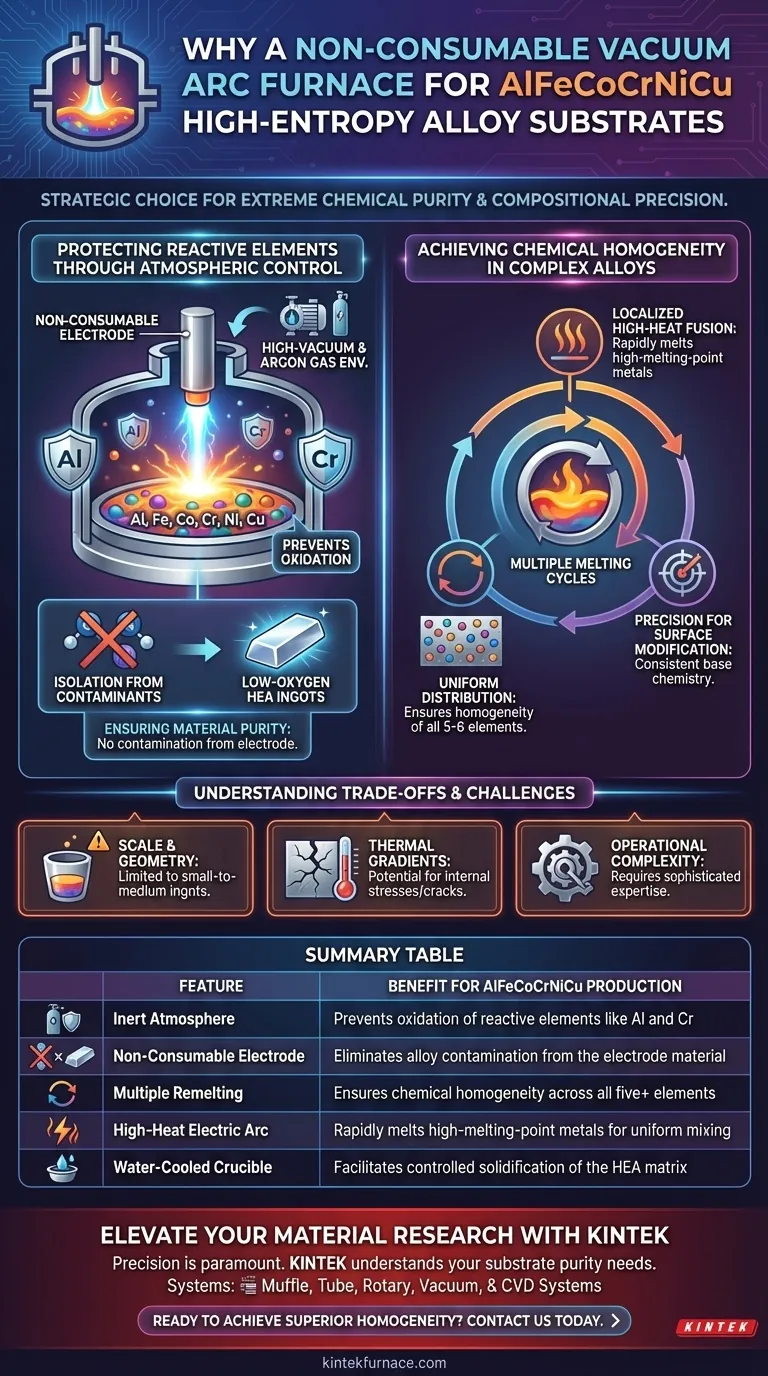

The selection of a non-consumable vacuum arc furnace is a strategic choice driven by the need for extreme chemical purity and compositional precision. By operating within a high-vacuum or inert gas environment, this equipment shields reactive elements like Aluminum from atmospheric oxidation. Furthermore, the use of non-consumable electrodes allows for repeated melting cycles, which are essential for ensuring the chemical uniformity of complex AlFeCoCrNiCu high-entropy alloy (HEA) ingots.

To successfully produce AlFeCoCrNiCu substrates, the melting process must overcome the dual challenges of high-temperature oxidation and the uneven mixing of multiple metallic elements. The non-consumable vacuum arc furnace solves this by providing a controlled, high-heat environment that preserves alloy purity while achieving a homogenous distribution of components.

Protecting Reactive Elements Through Atmospheric Control

Prevention of Oxidative Loss

Elements such as Aluminum (Al) and Chromium (Cr) are highly reactive and prone to rapid oxidation at elevated temperatures. The vacuum arc furnace eliminates this risk by evacuating the melting chamber and backfilling it with high-purity argon gas.

Isolation from Contaminants

By providing a sealed environment, the furnace isolates the molten pool from oxygen and nitrogen present in the air. This isolation is critical for producing low-oxygen HEA ingots that maintain their intended mechanical and chemical properties.

Ensuring Material Purity

The "non-consumable" nature of the electrode is vital; unlike consumable electrodes, it does not melt into the alloy. This ensures that the resulting substrate remains a high-purity metal matrix without unintended contamination from the electrode material itself.

Achieving Chemical Homogeneity in Complex Alloys

The Necessity of Multiple Melting Cycles

High-entropy alloys like AlFeCoCrNiCu consist of multiple elements with varying melting points and densities. The furnace allows for multiple melting cycles, which are necessary to stir the molten pool and ensure that all five or six elements are distributed evenly throughout the ingot.

Localized High-Heat Fusion

The electric arc generates localized high temperatures capable of quickly melting even high-melting-point metals within the mixture. This rapid fusion is the fundamental step in creating a stable, single-phase or multi-phase HEA structure.

Precision for Surface Modification

Because these ingots often serve as substrates for further surface treatments, compositional precision is non-negotiable. The vacuum arc furnace provides the consistency required to ensure that the substrate's base chemistry does not negatively impact subsequent modification layers.

Understanding the Trade-offs and Challenges

Limitations of Scale and Geometry

While the vacuum arc furnace produces high-quality material, it is often limited to producing small-to-medium-sized ingots. This makes it an excellent tool for laboratory research and high-precision substrate preparation but less efficient for bulk industrial manufacturing.

Thermal Gradient Issues

The rapid cooling often associated with the water-cooled copper crucibles in these furnaces can lead to internal stresses or specific solidification textures. If not managed carefully, these gradients may result in microscopic cracks or non-uniform grain structures within the AlFeCoCrNiCu matrix.

Operational Complexity

Maintaining a high vacuum and managing inert gas pressures requires sophisticated equipment and expertise. Any failure in the vacuum seal during the melting process can lead to the immediate spoilage of the entire alloy batch due to sudden oxidation.

How to Apply This to Your Project

When preparing AlFeCoCrNiCu substrates, your equipment choice should align with the final requirements of your alloy's performance and purity.

- If your primary focus is high chemical purity: Utilize the vacuum arc furnace with at least three to five "flip-and-remelt" cycles to ensure the complete distribution of reactive elements like Aluminum.

- If your primary focus is preventing element loss: Ensure the chamber is pre-evacuated to a high vacuum before backfilling with argon to create an ultra-clean environment for the electric arc.

- If your primary focus is subsequent surface modification: Prioritize the precision of the initial ingot composition, as the vacuum arc furnace is the most reliable tool for creating a stable foundation for coatings.

By leveraging the atmospheric control and melting precision of a non-consumable vacuum arc furnace, you ensure that the complex AlFeCoCrNiCu system achieves the high-entropy stability required for advanced engineering applications.

Summary Table:

| Feature | Benefit for AlFeCoCrNiCu Production |

|---|---|

| Inert Atmosphere | Prevents oxidation of reactive elements like Al and Cr |

| Non-Consumable Electrode | Eliminates alloy contamination from the electrode material |

| Multiple Remelting | Ensures chemical homogeneity across all five+ elements |

| High-Heat Electric Arc | Rapidly melts high-melting-point metals for uniform mixing |

| Water-Cooled Crucible | Facilitates controlled solidification of the HEA matrix |

Elevate Your Material Research with KINTEK

Precision is paramount when developing complex high-entropy alloys like AlFeCoCrNiCu. At KINTEK, we understand that the integrity of your research depends on the purity and uniformity of your substrates.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized lab high-temp furnaces designed for the most demanding metallurgical requirements. Our systems are fully customizable to solve your unique atmospheric and thermal challenges.

Ready to achieve superior chemical homogeneity and purity? Contact us today to discover how our advanced furnace solutions can empower your next breakthrough.

Visual Guide

References

- Ying Wang, Bin Li. Study on the Properties of TiC Coating Deposited by Spark Discharge on the Surface of AlFeCoCrNiCu High-Entropy Alloy. DOI: 10.3390/ma17164110

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the key applications of high vacuum furnaces? Unlock Purity and Performance in Critical Industries

- What is the difference between vacuum hardening and normal hardening? A Guide to Superior Surface Quality

- Which metals are prone to oxidation during melting? Protect with vacuum or inert gas furnaces

- What are the temperature-related precautions for using a vacuum furnace? Ensure Safety and Longevity in Your Lab

- How does the high-power rapid scanning preheating cycle affect material quality? Stabilize PBF-EB & Prevent Cracking

- What are the main components of a vacuum brazing oven? Discover the Key Parts for Superior Brazing

- How does the production efficiency of vacuum furnaces compare to conventional furnaces? Optimize Your Heat Treatment Process

- How do laboratory high-temperature furnaces achieve microstructure control in Ti-Nb-Zr alloys? Key Precision Techniques