At their core, high vacuum furnaces are used for sophisticated thermal processes where preventing atmospheric contamination is critical. The key applications are heat treatment, brazing, and sintering of advanced materials. These processes are indispensable in high-stakes industries such as aerospace, medical device manufacturing, and electronics, where material purity and performance are non-negotiable.

The fundamental value of a high vacuum furnace is not just its ability to heat materials, but its power to create a chemically inert environment. By removing reactive gases like oxygen and nitrogen, it enables the processing of sensitive materials to achieve properties—like superior strength, purity, and structural integrity—that are impossible in a conventional atmosphere.

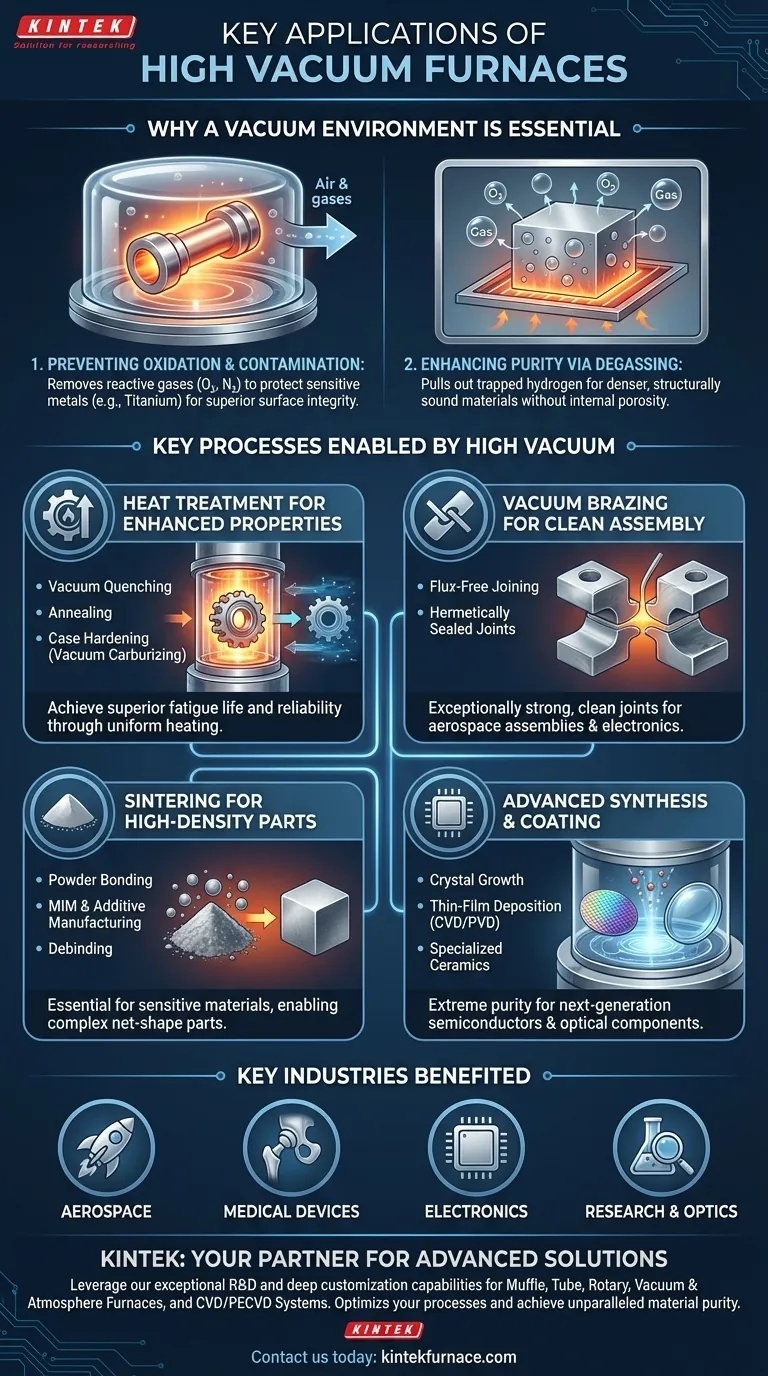

The Core Principle: Why a Vacuum Environment is Essential

The decision to use a vacuum furnace is driven by the need to control a material's chemistry and microstructure at high temperatures. A vacuum is not empty space; it's a highly controlled environment.

Preventing Oxidation and Contamination

At elevated temperatures, most metals and alloys react aggressively with oxygen and nitrogen in the air. This causes oxidation (scaling) and can form unwanted nitrides, which degrade the material's mechanical properties and surface finish.

High vacuum furnaces pump out these reactive gases, creating a "clean" environment. This is crucial for processing reactive metals like titanium, molybdenum, and tungsten, which would be ruined if heated in air.

Enhancing Material Purity Through Degassing

Many materials contain trapped or dissolved gases (like hydrogen) from their initial manufacturing stages. When heated, these gases can create internal porosity, leading to weakness and premature failure.

A vacuum furnace pulls these trapped gases out of the material as it is heated, a process known as degassing. This results in a denser, purer, and more structurally sound final component.

Achieving Superior Surface Integrity

Because a vacuum environment prevents oxidation, components emerge from the furnace with a bright, clean surface. This eliminates the need for post-process cleaning or machining to remove scale, saving time and preserving the precise dimensions of the part.

Key Processes Enabled by High Vacuum

The controlled environment of a vacuum furnace unlocks several high-performance manufacturing processes that are difficult or impossible to perform otherwise.

Heat Treatment for Enhanced Mechanical Properties

Heat treatment modifies the microstructure of a material to achieve desired characteristics like hardness, strength, and ductility.

Processes like vacuum quenching (rapid cooling), annealing (stress relieving), and case hardening (vacuum carburizing) are performed in vacuum to ensure uniform heating and prevent surface degradation, resulting in parts with superior fatigue life and reliability.

Joining and Assembly with Vacuum Brazing

Vacuum brazing is a process used to join two or more components using a filler metal that melts at a lower temperature than the base materials.

Performing this in a vacuum eliminates the need for corrosive fluxes. The result is an exceptionally strong, clean, and hermetically sealed joint, which is critical for complex aerospace assemblies like turbine blades and sensitive electronic components.

Forming High-Density Parts via Sintering

Sintering is the process of heating compacted powder materials to just below their melting point, causing the particles to bond together and form a solid, dense object.

Using a vacuum is essential for sintering materials that are highly sensitive to oxygen. It is also a key step in metal injection molding (MIM) and additive manufacturing, where debinding (removing a polymer binder) and sintering are performed to create a final, dense metal part.

Advanced Material Synthesis and Coating

The extreme purity of a high vacuum environment is necessary for creating next-generation materials.

This includes crystal growth for the semiconductor and optics industries, thin-film deposition (CVD/PVD) for electronics and wear-resistant coatings, and the synthesis of specialized ceramics and composites for material science research.

Understanding the Trade-offs

While powerful, high vacuum furnaces are not the right tool for every job. Their benefits come with specific operational considerations.

Higher Initial Cost and Complexity

Vacuum furnaces are more expensive to purchase and operate than conventional atmosphere furnaces. The systems require vacuum pumps, sophisticated controls, and more robust chamber construction, all of which add to the initial investment and maintenance overhead.

Slower Cycle Times

Achieving a deep vacuum is not instantaneous. The time required to pump the chamber down to the target pressure (pump-down time) adds to the total process cycle. For high-volume, low-spec parts, this can be a significant bottleneck compared to faster atmosphere furnaces.

Not a Universal Solution

For many common heat-treating applications involving non-reactive steels, a controlled atmosphere (e.g., nitrogen or argon) furnace is often more cost-effective. If slight surface oxidation is acceptable or can be easily removed, the expense and complexity of a high vacuum system may be unnecessary.

Making the Right Choice for Your Goal

The decision to use a high vacuum furnace should be driven by the end-use requirements of your component.

- If your primary focus is mechanical strength and fatigue life (e.g., aerospace parts): Use vacuum for critical heat treatments (annealing, quenching) and brazing to guarantee material integrity and prevent hidden flaws.

- If your primary focus is purity and biocompatibility (e.g., medical implants): Use vacuum for sintering and degassing to ensure the material is free from contaminants and has a clean, unblemished surface.

- If your primary focus is advanced electronic or optical properties (e.g., semiconductors): Use vacuum for crystal growth, annealing, and thin-film deposition to create materials with the required atomic-level purity and structure.

- If your primary focus is creating complex net-shape parts from powder (e.g., 3D printing): Use vacuum for the debinding and sintering cycles to achieve full density and excellent mechanical properties without compromising the material.

Ultimately, choosing a high vacuum furnace is an investment in achieving material properties that are fundamentally impossible in any other environment.

Summary Table:

| Application | Key Processes | Industries Benefited |

|---|---|---|

| Heat Treatment | Vacuum quenching, annealing, case hardening | Aerospace, Medical Devices, Electronics |

| Brazing | Flux-free joining with filler metals | Aerospace, Electronics |

| Sintering | Powder bonding, debinding, MIM | Additive Manufacturing, Medical Implants |

| Material Synthesis | Crystal growth, thin-film deposition | Semiconductors, Optics, Research |

Ready to achieve unparalleled material purity and performance with a high vacuum furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're in aerospace, medical device manufacturing, or electronics, we can help you optimize processes like heat treatment, brazing, and sintering. Contact us today to discuss how our high vacuum furnaces can elevate your lab's efficiency and results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today