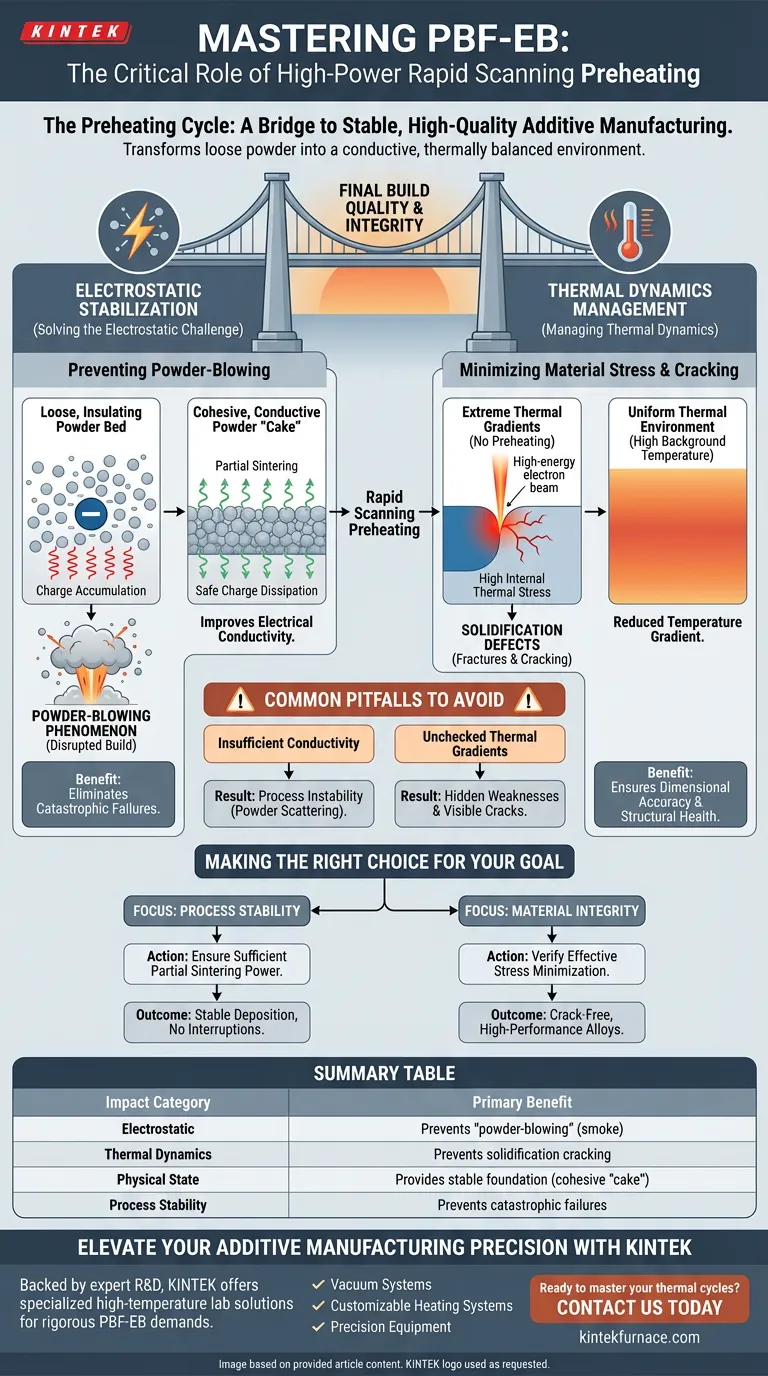

The high-power rapid scanning preheating cycle is a fundamental process step in Electron Beam Powder Bed Fusion (PBF-EB) that directly dictates the structural integrity and stability of the final build. By executing this cycle before each layer is deposited, the system stabilizes the powder bed electrostatically and thermally, preventing catastrophic process failures like powder displacement and material cracking.

Core Takeaway The preheating cycle is not simply about raising temperature; it is a stabilization technique. It transforms loose powder into a conductive, semi-solid state to prevent "powder blowing" and equalizes thermal gradients to stop parts from cracking during solidification.

Solving the Electrostatic Challenge

The primary function of the preheating cycle is to alter the physical state of the powder bed to accommodate the high-energy electron beam. Without this step, the physics of the electron beam would disrupt the build process.

The Mechanism of Partial Sintering

The rapid scanning process lightly fuses the individual powder particles together.

This results in partial sintering, creating a cohesive "cake" rather than a bed of loose dust. This physical change is the foundation for a stable build environment.

Preventing Powder-Blowing

Electron beams deposit a significant negative charge into the material. If the powder remains loose and insulating, this charge accumulates rapidly.

The resulting electrostatic repulsion causes the powder-blowing phenomenon, where particles are violently scattered (often resembling smoke). Partial sintering improves the electrical conductivity of the bed, allowing the charge to dissipate safely and preventing this disruption.

Managing Thermal Dynamics

Beyond electrical issues, the PBF-EB process involves extreme temperature changes. The preheating cycle acts as a thermal buffer to protect material quality.

Reducing Internal Thermal Stress

Rapid heating and cooling cycles naturally induce stress within a material.

By maintaining a high background temperature through preheating, the process reduces the temperature gradient between the molten pool and the surrounding material. This reduction in internal thermal stress is vital for dimensional accuracy and structural health.

Eliminating Solidification Defects

Certain high-performance materials are highly sensitive to thermal cracking.

If the thermal shock is too great during the solidification stage, the material will fracture. The preheating cycle ensures the thermal environment remains consistent, effectively preventing defects and cracking in these sensitive alloys.

Common Pitfalls to Avoid

While preheating is beneficial, it relies on precise execution to function correctly. Understanding the limits of this mechanism is key to analyzing process failures.

The Risk of Insufficient Conductivity

If the preheating scanning is not "rapid" or high-power enough to achieve adequate partial sintering, the electrical conductivity will remain too low.

This inevitably leads to charge accumulation. The immediate consequence is process instability, characterized by the scattering of powder and the interruption of layer deposition.

Unchecked Thermal Gradients

In scenarios where the preheating cycle does not uniformly saturate the build area, thermal pockets can remain.

Even if the powder does not blow away, these cooler areas reintroduce the risk of thermal stress. This undermines the material benefits, leading to hidden structural weaknesses or visible cracks upon cooling.

Making the Right Choice for Your Goal

To maximize the quality of your PBF-EB components, you must prioritize the specific function of the preheating cycle based on your material's vulnerabilities.

- If your primary focus is Process Stability: Ensure the preheating power is sufficient to achieve partial sintering, which improves conductivity and eliminates the risk of powder blowing.

- If your primary focus is Material Integrity: Verify that the preheating cycle effectively minimizes internal stress to prevent cracking during the solidification of sensitive materials.

The preheating cycle is the critical bridge that transforms a volatile powder bed into a stable, conductive, and thermally balanced environment for high-quality additive manufacturing.

Summary Table:

| Impact Category | Primary Function | Benefit to Material Quality |

|---|---|---|

| Electrostatic | Partial sintering of powder particles | Improves conductivity & prevents "powder-blowing" (smoke) |

| Thermal Dynamics | Reduction of thermal gradients | Minimizes internal stress and prevents solidification cracking |

| Physical State | Formation of a cohesive powder "cake" | Provides a stable foundation for consistent layer deposition |

| Process Stability | Electrostatic charge dissipation | Prevents catastrophic process failures and interruptions |

Elevate Your Additive Manufacturing Precision with KINTEK

Don't let powder instability or thermal stress compromise your material integrity. Backed by expert R&D and manufacturing, KINTEK offers specialized high-temperature lab solutions, including vacuum and customizable heating systems designed to meet the rigorous demands of advanced additive manufacturing workflows.

Whether you are optimizing PBF-EB processes or researching new alloys, our team provides the precision equipment necessary to ensure a stable, conductive, and thermally balanced environment.

Ready to master your thermal cycles? Contact us today to discover how our customizable furnace solutions can enhance your lab's performance!

Visual Guide

References

- Tobia Romano, Maurizio Vedani. Metal additive manufacturing for particle accelerator applications. DOI: 10.1103/physrevaccelbeams.27.054801

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the key benefits of vacuum furnace technology? Achieve Superior Material Quality and Consistency

- What are the operational benefits of multi-chamber vacuum furnaces? Boost Throughput and Cut Costs

- Why is a vacuum high-temperature box furnace critical for Ti-11Cr alloys? Ensure High Purity Homogenization

- Why is a vacuum drying oven preferred for Al2O3/TiC mixed powders? Prevent Oxidation & Improve Density

- What infrared materials can be produced using high temperature vacuum furnaces? Discover ZnS, ZnSe, and More

- How does vacuum level affect the annealing process? Optimize Material Purity and Performance

- What are the benefits of using graphite felt in vacuum furnaces? Achieve Superior Thermal Efficiency & Stability

- Why are some vacuum furnaces backfilled with a partial pressure gas? Prevent Alloy Depletion in High-Temp Processes