At its core, vacuum furnace technology delivers an exceptionally clean, highly controllable, and repeatable environment for the thermal processing of materials. The primary benefits are the prevention of oxidation and contamination, precise control over the heating and cooling cycles, and the ability to achieve uniform material properties that are often impossible in a conventional atmosphere furnace. This results in superior product quality, reduced post-processing steps, and consistent, reliable outcomes.

While often chosen for preventing surface contamination, the true power of a vacuum furnace is its ability to fundamentally alter and control a material's metallurgical properties. It transforms heat treatment from a bulk process into a precise engineering tool for creating high-value, mission-critical components.

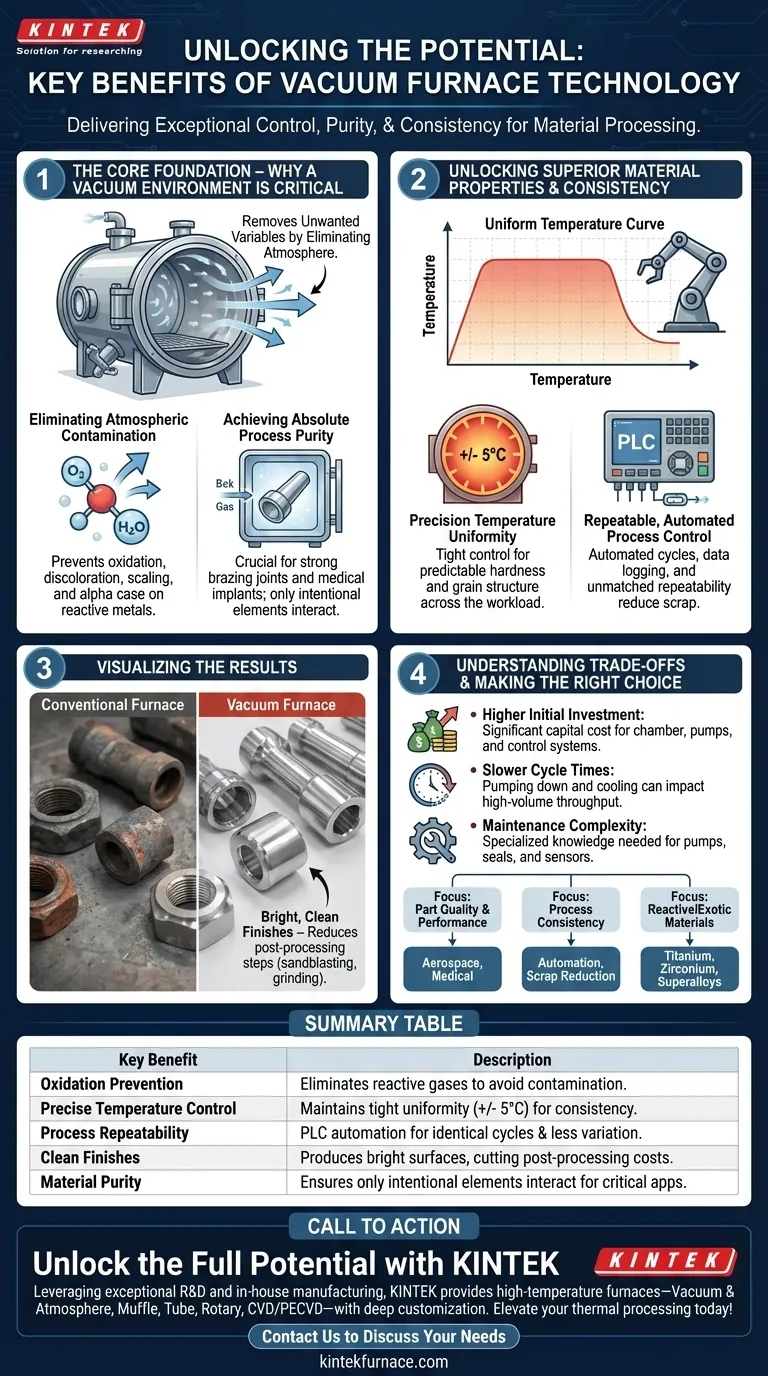

The Foundation: Why a Vacuum Environment is Critical

A vacuum furnace operates on a simple but powerful principle: removing the atmosphere removes unwanted variables. This creates a pristine environment that is the basis for all subsequent benefits.

Eliminating Atmospheric Contamination

By removing air, a vacuum furnace eliminates oxygen, water vapor, and other reactive gases. This is the single most important function.

Without these gases, oxidation and other detrimental surface reactions simply cannot occur. This prevents discoloration, scaling, and the formation of an undesirable "alpha case" on reactive metals like titanium.

Achieving Absolute Process Purity

The vacuum environment ensures that the only elements interacting with the part are the ones you intentionally introduce, such as a specific backfill gas like nitrogen or argon.

This level of purity is essential for processes like brazing, where a clean surface is non-negotiable for achieving a strong, void-free joint, or for medical implants, where surface contamination is unacceptable.

Unlocking Superior Material Properties and Consistency

With a pure environment established, the furnace's advanced control systems can produce materials with exceptional quality and repeatability.

Precision Temperature Uniformity

Modern vacuum furnaces provide extremely tight temperature control, often with a uniformity of +/- 5°C across the entire workload.

This ensures that every part in the batch, regardless of its position, experiences the exact same thermal cycle. This uniformity is critical for predictable hardness, grain structure, and stress relief.

Repeatable, Automated Process Control

Vacuum furnaces are managed by Programmable Logic Controllers (PLCs) that automate the entire treatment cycle.

Operators can program precise heating ramps, soak times, vacuum levels, and controlled cooling or gas quenching sequences. Every cycle is executed identically and recorded with extensive data logging, guaranteeing unmatched process repeatability from batch to batch.

Bright, Clean Finishes

A direct result of preventing oxidation is that parts emerge from the furnace with a bright, clean surface finish.

This often eliminates the need for costly and time-consuming secondary operations like sandblasting, chemical cleaning, or grinding, reducing overall production costs and lead times.

Understanding the Trade-offs

While powerful, vacuum furnace technology is not a universal solution. An objective evaluation requires acknowledging its specific demands.

Higher Initial Investment

Vacuum furnaces represent a significant capital expenditure compared to their atmospheric counterparts. The cost includes the furnace chamber, sophisticated pumping systems, and advanced control instrumentation.

Slower Cycle Times

Achieving a deep vacuum (pumping down) and then cooling the load can take longer than in an atmospheric furnace. This can impact overall throughput, a key consideration for high-volume production.

Maintenance Complexity

The systems that create and measure the vacuum—including pumps, seals, valves, and sensors—require specialized knowledge for routine maintenance and troubleshooting to ensure peak performance.

Making the Right Choice for Your Goal

Deciding on a vacuum furnace requires aligning its capabilities with your specific manufacturing objectives.

- If your primary focus is part quality and performance: A vacuum furnace is the superior choice for creating components with optimal strength, fatigue life, and purity, especially for demanding industries like aerospace or medical.

- If your primary focus is process consistency and repeatability: The automation and data logging inherent to vacuum furnaces provide an unparalleled level of control, drastically reducing process variation and scrap rates.

- If your primary focus is processing reactive or exotic materials: For metals like titanium, zirconium, or certain superalloys, a vacuum environment is not just beneficial—it is an absolute requirement.

By understanding these principles, you can confidently determine if a vacuum furnace is the strategic investment needed to elevate your material processing capabilities.

Summary Table:

| Key Benefit | Description |

|---|---|

| Oxidation Prevention | Eliminates oxygen and reactive gases to avoid surface contamination and scaling. |

| Precise Temperature Control | Maintains tight uniformity (e.g., +/- 5°C) for consistent material properties. |

| Process Repeatability | Uses PLC automation for identical cycles, reducing variation and scrap rates. |

| Clean Finishes | Produces bright surfaces, cutting post-processing costs like sandblasting. |

| Material Purity | Ensures only intentional elements interact, vital for brazing and medical implants. |

Unlock the full potential of your materials with KINTEK's advanced vacuum furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces—including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems—with strong deep customization to meet your unique experimental needs. Enhance quality, consistency, and efficiency in industries like aerospace and medical. Contact us today to discuss how we can elevate your thermal processing capabilities!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion