At its core, a high-temperature vacuum furnace is the ideal environment for producing specific, high-purity infrared (IR) optical materials. The most common examples are zinc sulfide (ZnS) and zinc selenide (ZnSe), which are prized for their exceptional strength and hardness, making them suitable for IR windows and lenses exposed to harsh conditions.

The primary function of the vacuum furnace in this context is not just heat, but control. By eliminating atmospheric gases, the furnace creates an ultra-clean environment that prevents contamination and unwanted chemical reactions, enabling the synthesis of materials with the precise optical and structural properties required for high-performance infrared applications.

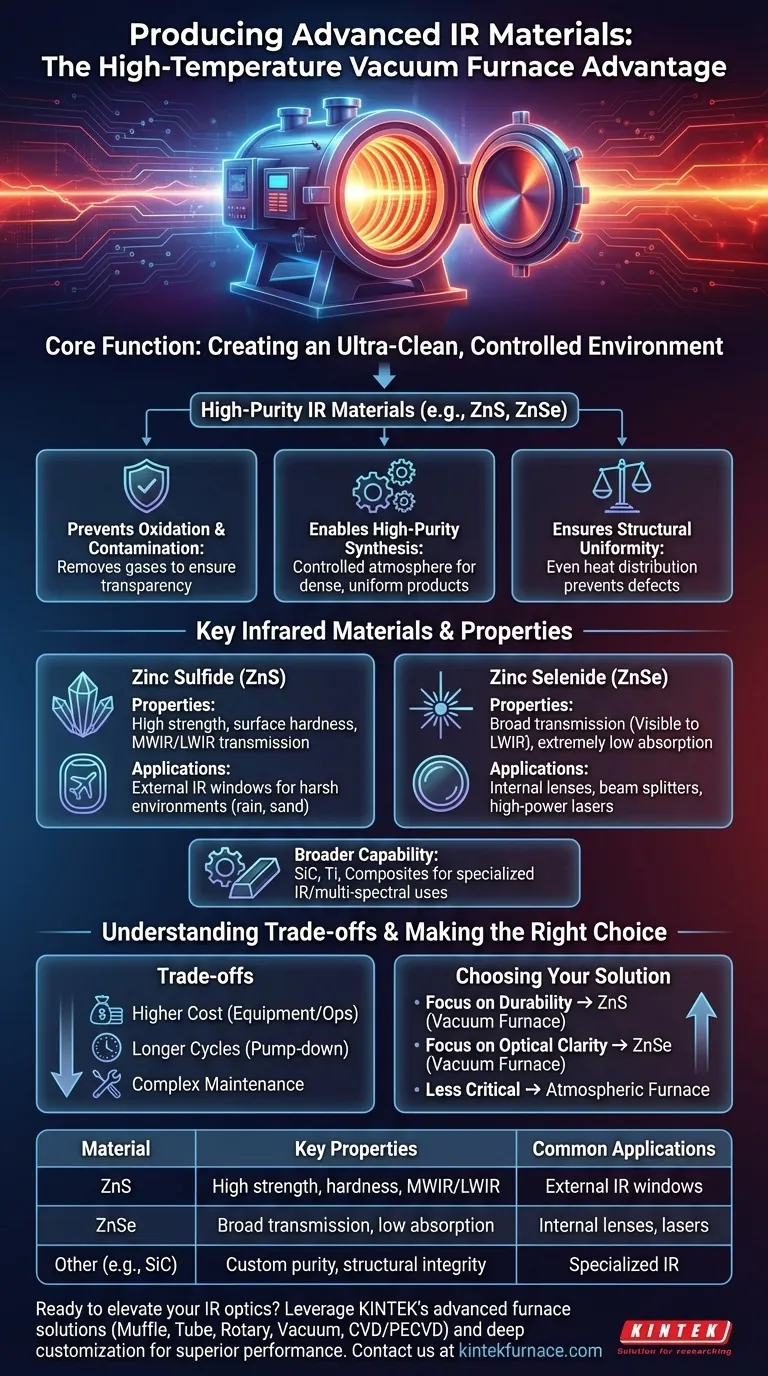

Why a Vacuum Furnace is Essential for IR Optics

The decision to use a high-temperature vacuum furnace is driven by the stringent purity and structural requirements of advanced optical materials. The process is fundamentally about creating a perfect, controlled environment.

Preventing Oxidation and Contamination

Many materials used in infrared optics are highly reactive with oxygen and other atmospheric gases, especially at high temperatures. A vacuum removes these contaminants.

This prevention of oxidation is critical for achieving the desired transparency in the infrared spectrum. Even minor impurities or oxide layers can absorb IR radiation, rendering the material useless for its intended application.

Enabling High-Purity Synthesis

The furnace's controlled atmosphere allows for the synthesis of materials from high-purity precursors. Processes like vacuum pressure sintering rely on this environment to create a dense, uniform final product.

This level of control ensures high repeatability between production runs, which is essential for manufacturing reliable optical components with consistent performance characteristics.

Ensuring Structural Uniformity

Modern vacuum furnaces provide exceptional temperature field balance. This means the heat is distributed evenly throughout the material during the sintering or growth process.

Uniform heating prevents internal stresses, cracks, and density variations, ensuring the final component has outstanding structural integrity and consistent optical properties across its entire surface.

Key Infrared Materials and Their Properties

While the furnace technology is versatile, a few key materials stand out for their specific applications in the infrared domain.

Zinc Sulfide (ZnS)

Zinc Sulfide is a robust ceramic material known for its excellent transmission in the mid-wave infrared (MWIR) and long-wave infrared (LWIR) ranges.

Its superior strength and surface hardness make it a preferred choice for external-facing optics, such as windows on aircraft or sensor systems that must withstand abrasive environments like rain, sand, and high-speed airflow.

Zinc Selenide (ZnSe)

Zinc Selenide offers a very broad transmission range, from the visible spectrum all the way through the LWIR. It has extremely low absorption, making it ideal for high-power laser applications.

While not as hard as ZnS, ZnSe is often used for internal lenses, beam splitters, and windows in controlled environments where its superior optical clarity is the primary concern.

Broader Advanced Material Capability

Beyond these specific IR materials, the technology supports a wide range of advanced material production. This includes other ceramics like silicon carbide (SiC), high-purity metals like titanium (Ti), and various composites that may have specialized infrared or multi-spectral applications.

Understanding the Trade-offs

The precision and control offered by high-temperature vacuum furnaces come with significant considerations. This method is not universally applicable and involves clear trade-offs.

Higher Equipment and Operational Costs

Vacuum furnaces are complex systems with a high initial investment cost. The pumps, chambers, and control systems required to maintain a high vacuum are expensive to purchase and operate.

Longer Processing Cycles

Achieving a high vacuum is not instantaneous. The pump-down time to remove atmospheric gases can significantly add to the total production cycle, making it slower than atmospheric furnace processes.

Complex Maintenance Requirements

Maintaining the integrity of the vacuum system requires stringent and specialized maintenance protocols. Seals, pumps, and sensors must be regularly inspected and serviced to prevent leaks and ensure consistent performance.

Making the Right Choice for Your Application

Selecting the correct manufacturing process depends entirely on the performance requirements and constraints of your final product.

- If your primary focus is durability in harsh environments: The high-purity ZnS produced in a vacuum furnace is the industry standard for external IR windows.

- If your primary focus is maximum optical clarity for lasers: The low-absorption properties of vacuum-synthesized ZnSe make it the superior choice.

- If your application is less sensitive to contamination: For some metals or less critical components, a simpler low-vacuum or atmospheric furnace may be a more cost-effective solution.

Ultimately, using a high-temperature vacuum furnace is a deliberate choice for applications where material purity and structural perfection directly translate to mission-critical performance.

Summary Table:

| Material | Key Properties | Common Applications |

|---|---|---|

| Zinc Sulfide (ZnS) | High strength, hardness, MWIR/LWIR transmission | External IR windows, lenses in abrasive conditions |

| Zinc Selenide (ZnSe) | Broad transmission (visible to LWIR), low absorption | Internal lenses, beam splitters, high-power laser systems |

| Other Materials (e.g., SiC, Ti) | Custom purity and structural integrity | Specialized IR and multi-spectral applications |

Ready to elevate your infrared optics with precision-engineered materials? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for materials like ZnS and ZnSe. Contact us today to discuss how we can help you achieve superior performance and reliability in your applications!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions