A vacuum high-temperature box furnace is indispensable for the processing of Ti-11Cr alloys because it simultaneously delivers precise thermal control and atmospheric isolation. Specifically, it maintains the 900°C environment required for beta-phase homogenization while creating a vacuum that prevents the titanium from reacting with active gases, thereby preserving the material's mechanical integrity.

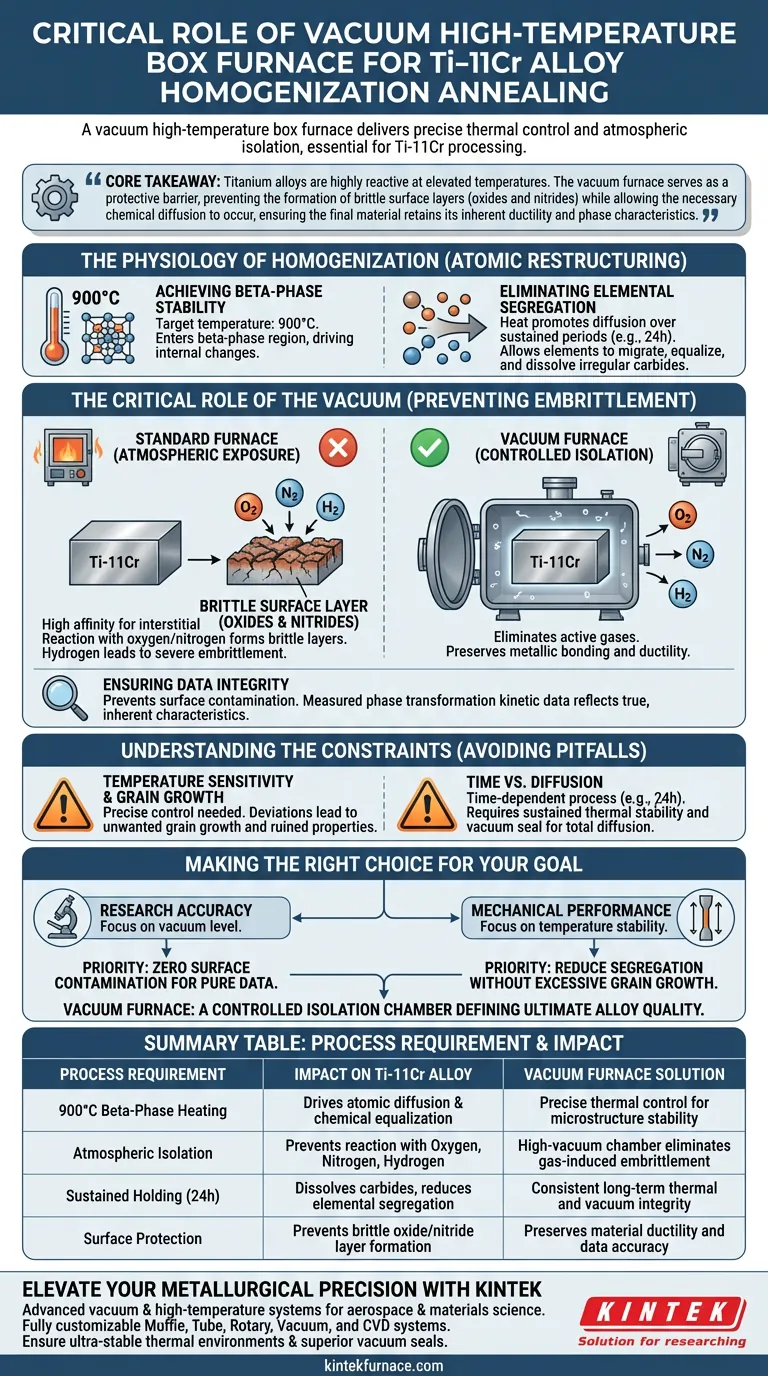

Core Takeaway Titanium alloys are highly reactive at elevated temperatures. The vacuum furnace serves as a protective barrier, preventing the formation of brittle surface layers (oxides and nitrides) while allowing the necessary chemical diffusion to occur, ensuring the final material retains its inherent ductility and phase characteristics.

The Physiology of Homogenization

To understand the equipment choice, you must first understand the metallurgical goal. Homogenization is not merely heating; it is about restructuring the alloy at the atomic level.

Achieving Beta-Phase Stability

For Ti-11Cr alloys, the target temperature for homogenization is typically 900°C.

At this specific thermal plateau, the alloy enters the beta-phase region. This high temperature is the energy source required to drive the internal changes within the material.

Eliminating Elemental Segregation

In the "as-cast" structure of an alloy, chemical components are often unevenly distributed.

The heat provided by the furnace promotes the diffusion of chemical components. Over sustained periods (often up to 24 hours), this allows elements to migrate and equalize, reducing segregation and dissolving irregular carbides that could otherwise act as failure points.

The Critical Role of the Vacuum

The primary challenge with Titanium (Ti) is its high affinity for interstitial elements like oxygen, nitrogen, and hydrogen. A standard furnace would destroy the alloy's properties at 900°C.

Preventing Material Embrittlement

At high temperatures, titanium acts like a sponge for active gases.

If exposed to air, the alloy will react with oxygen and nitrogen to form hard, brittle surface layers (oxides and nitrides). Additionally, the absorption of hydrogen can lead to severe embrittlement. A vacuum environment effectively eliminates these gases, preserving the metallic bonding and ductility of the alloy.

Ensuring Data Integrity

For researchers and metallurgists, data accuracy is paramount.

If an oxide layer forms on the surface, it alters the material's behavior. By preventing surface contamination, the vacuum furnace ensures that any measured phase transformation kinetic data reflects the true, inherent characteristics of the Ti-11Cr alloy, rather than artifacts caused by environmental reaction.

Understanding the Constraints

While the vacuum furnace is the correct tool, the process requires strict management to avoid common pitfalls.

Temperature Sensitivity and Grain Growth

Temperature control must be precise.

The microstructure of titanium alloys is extremely sensitive. Deviations from the target temperature can lead to drastic transitions in microstructure types or unwanted grain growth. An erratic furnace can ruin the mechanical properties even if the vacuum is perfect.

Time vs. Diffusion

Homogenization is a time-dependent process.

Achieving a uniform chemical distribution requires holding the temperature for extended periods (e.g., 24 hours). The furnace must be capable of maintaining both the thermal stability and the vacuum seal for this duration to facilitate total diffusion.

Making the Right Choice for Your Goal

When configuring your thermal processing cycle for Ti-11Cr, align your parameters with your specific end-goal.

- If your primary focus is Research Accuracy: Prioritize the vacuum level to ensure zero surface contamination, allowing for pure phase transformation kinetic data.

- If your primary focus is Mechanical Performance: Prioritize precise temperature stability to reduce elemental segregation without inducing excessive grain growth or embrittlement.

The vacuum furnace is not just a heater; it is a controlled isolation chamber that defines the ultimate quality of your alloy.

Summary Table:

| Process Requirement | Impact on Ti-11Cr Alloy | Vacuum Furnace Solution |

|---|---|---|

| 900°C Beta-Phase Heating | Drives atomic diffusion and chemical equalization | Precise thermal control for microstructure stability |

| Atmospheric Isolation | Prevents reaction with Oxygen, Nitrogen, and Hydrogen | High-vacuum chamber eliminates gas-induced embrittlement |

| Sustained Holding (24h) | Dissolves carbides and reduces elemental segregation | Consistent long-term thermal and vacuum integrity |

| Surface Protection | Prevents brittle oxide/nitride layer formation | Preserves material ductility and data accuracy |

Elevate Your Metallurgical Precision with KINTEK

Don't compromise the integrity of your Ti-11Cr alloys with inferior thermal processing. KINTEK’s advanced vacuum and high-temperature systems are engineered specifically for the rigorous demands of aerospace and materials science research.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific homogenization and annealing requirements. Our furnaces provide the ultra-stable thermal environments and superior vacuum seals necessary to prevent embrittlement and ensure uniform chemical distribution.

Ready to optimize your lab's high-temperature processes? Contact us today to discuss your unique needs with our technical team.

Visual Guide

References

- JoAnn Ballor, Carl J. Boehlert. Lattice Parameter Evolution during the β-to-α and β-to-ω Transformations of Iron- and Aluminum-Modified Ti-11Cr(at.%). DOI: 10.3390/cryst14020145

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What advantages does the non-linear processing in a vacuum furnace offer? Achieve Precise Material Control

- Why are vacuum sintering furnaces important in manufacturing? Unlock Purity, Strength, and Precision

- How does high-temperature sintering furnace setting influence BaTiO3 microstructure? Optimize Sputtering Performance

- What processes are performed in a high-temperature vacuum furnace? Achieve Purity and Precision in Material Processing

- Why is a high-temperature homogenization furnace treatment necessary for (CoCrNi)94Al3Ti3 alloys? Ensure Metal Purity

- Why is a vacuum oven necessary for drying CoPc-NH2 powders? Protect Catalyst Purity and Active Sites

- What is a vacuum furnace? Precision Heating for Purity and Performance

- Why is a multi-stage vacuum evaporation system utilized in FMDS treatment? Maximize Efficiency and Resource Recovery