The primary advantage of non-linear processing in a vacuum furnace is the ability to execute highly complex, multi-stage heating and cooling profiles with exceptional precision. This level of control, impossible in conventional furnaces, allows you to manipulate a material's microstructure to achieve specific, predictable properties while maintaining absolute purity.

The core challenge in advanced heat treatment is not just reaching a temperature, but controlling the entire thermal journey of a component. A vacuum furnace excels by removing atmospheric variables, enabling highly predictable and clean results through purely radiant heat and precisely managed energy input.

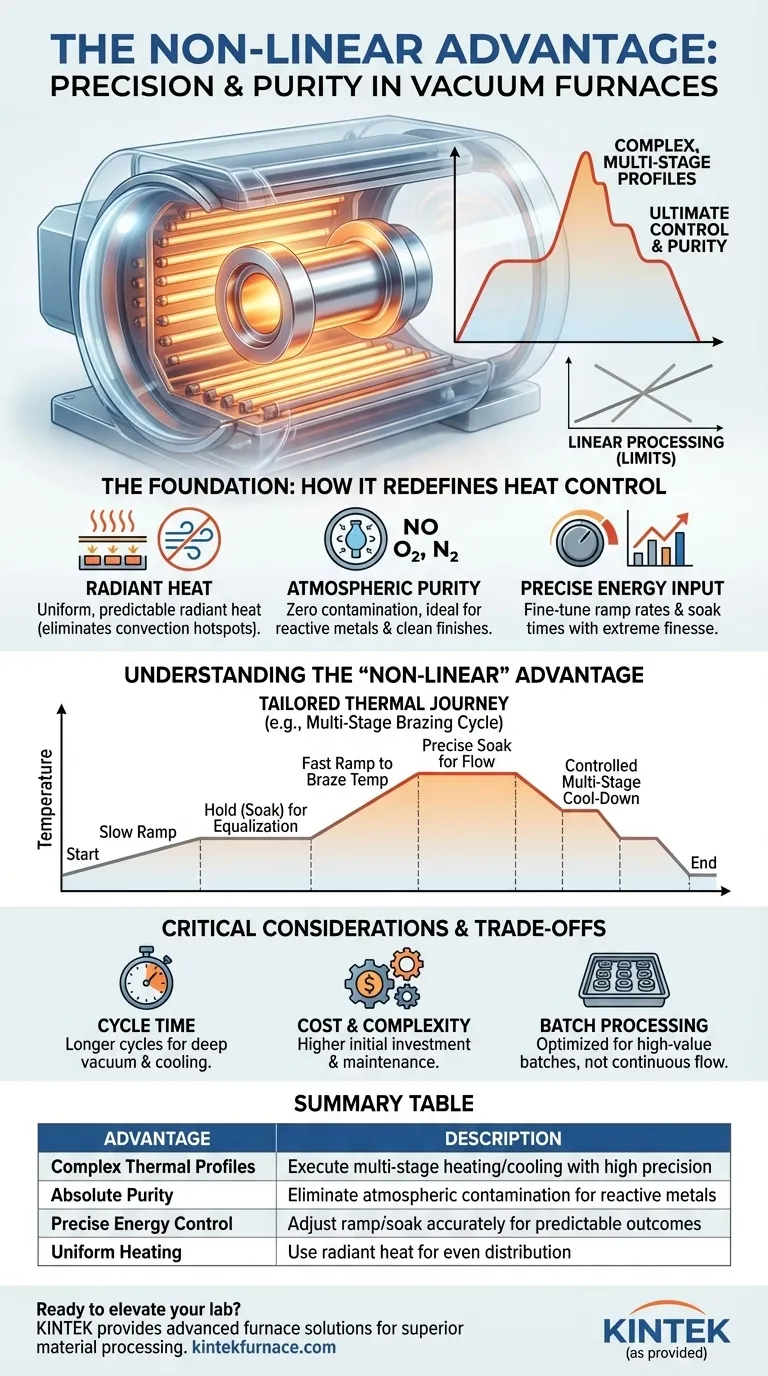

The Foundation: How a Vacuum Furnace Redefines Heat Control

To understand the benefits, we must first look at the fundamental principles a vacuum environment enables. It changes the very physics of how heat is applied to a material.

Eliminating Convection for Pure Radiant Heat

In a standard furnace, air creates convection currents that cause uneven heating and unpredictable temperature fluctuations. A vacuum furnace removes virtually all air molecules.

This forces heat transfer to occur primarily through radiation from the heating elements. This method is far more uniform and predictable, eliminating the hot and cold spots that can compromise a part's integrity.

Achieving Absolute Atmospheric Purity

The sealed, evacuated chamber is the ultimate defense against contamination. It prevents oxygen, nitrogen, and other atmospheric gases from reacting with the material's surface at high temperatures.

This is critical for processing reactive metals like titanium or superalloys, and it ensures a clean, bright finish on parts without any surface oxidation or discoloration.

Unlocking Precise Energy Input

Modern vacuum furnaces use sophisticated controls for their electric heating elements. The power input can be adjusted with extreme finesse.

This allows for precise control over not just the final temperature, but also the rate of temperature change (the ramp rate) and the duration of any holds (soaks).

Understanding the "Non-Linear" Advantage

The term "non-linear" refers to the ability to create thermal profiles that do not follow a simple, straight-line path from start to finish. This capability is a direct result of the environmental and energy control discussed above.

What "Non-Linear" Really Means

It is the capacity to design and execute a complex recipe of heating, soaking, and cooling steps tailored to a specific metallurgical outcome.

Instead of a simple "heat to X and cool," you can program a sequence of different ramp rates and hold times.

Example: A Multi-Stage Brazing Cycle

Consider a complex brazing process. It might require a slow initial ramp to prevent thermal shock, a short hold to equalize temperature, a faster ramp to the brazing temperature, a precise soak for the filler metal to flow, and finally a controlled, multi-stage cool-down to prevent stress fractures.

This intricate, non-linear path is only possible when you have the absolute control a vacuum furnace provides.

Critical Considerations and Trade-offs

While powerful, vacuum furnaces are not the universal solution. Objectivity requires acknowledging their specific trade-offs.

Cycle Time

Achieving a deep vacuum takes time, as does cooling parts in a near-void. Overall cycle times can be longer compared to conventional atmosphere furnaces that use fans for forced convection cooling.

Cost and Complexity

Vacuum furnaces are sophisticated systems involving vacuum pumps, sealed chambers, and advanced controllers. The initial investment and ongoing maintenance are typically higher than for simpler furnace designs.

Batch Processing Nature

Most vacuum furnaces are designed for batch processing. While ideal for high-value components, this may not be efficient for continuous, high-volume production where a conveyor-style furnace might be more appropriate.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace should be driven by the specific requirements of your material and desired outcome.

- If your primary focus is material purity and preventing oxidation: The sealed vacuum environment is non-negotiable for processing reactive metals, medical implants, or aerospace components.

- If your primary focus is achieving complex microstructures: The precise, "non-linear" control over multi-stage heating and cooling cycles is the key advantage for advanced hardening, brazing, and annealing.

- If your primary focus is high-volume, simple heat treatment: A conventional atmosphere or continuous belt furnace might be a more cost-effective solution, provided minor surface oxidation is acceptable.

By understanding that a vacuum furnace offers ultimate control over the thermal environment, you can confidently select it for processes where precision, purity, and repeatability are paramount.

Summary Table:

| Advantage | Description |

|---|---|

| Complex Thermal Profiles | Execute multi-stage heating and cooling with high precision for tailored material properties. |

| Absolute Purity | Eliminate atmospheric contamination, ideal for reactive metals and clean finishes. |

| Precise Energy Control | Adjust ramp rates and soak times accurately for predictable outcomes. |

| Uniform Heating | Use radiant heat to avoid hot spots and ensure even temperature distribution. |

Ready to elevate your lab's capabilities with advanced vacuum furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior material processing. Contact us today to discuss how we can help you achieve unparalleled precision and purity in your heat treatments!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing