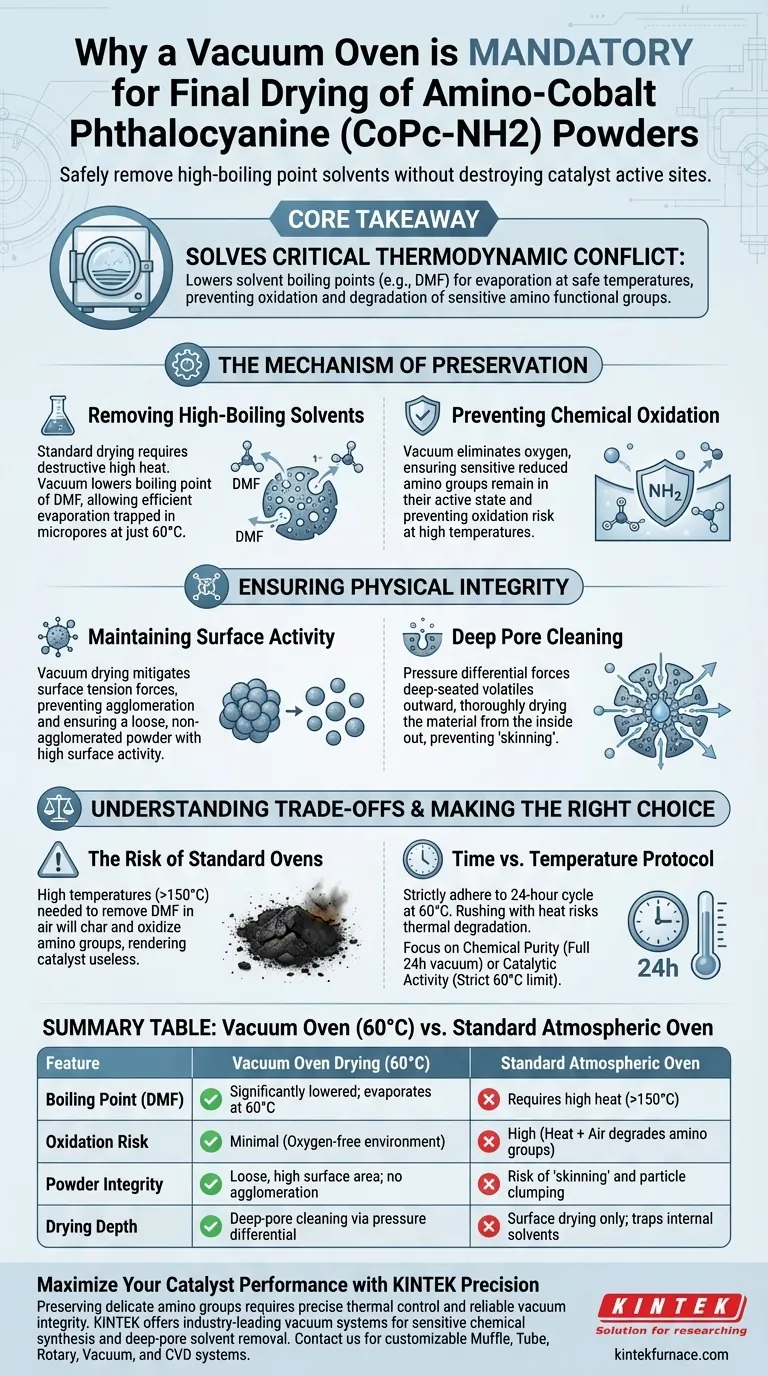

The use of a vacuum oven is mandatory for drying amino-cobalt phthalocyanine (CoPc-NH2) powders to safely remove high-boiling point solvents without destroying the catalyst's active sites. Specifically, it enables the removal of stubborn solvents like dimethylformamide (DMF) at a safe temperature of 60°C over 24 hours, effectively bypassing the need for destructive high-heat environments.

Core Takeaway The vacuum oven solves a critical thermodynamic conflict: it lowers the boiling point of trapped solvents like DMF so they can evaporate at temperatures that do not oxidize or degrade the sensitive amino functional groups essential for the catalyst's performance.

The Mechanism of Preservation

Removing High-Boiling Solvents

The synthesis of CoPc-NH2 often involves dimethylformamide (DMF), a solvent with a high boiling point that is difficult to remove under standard atmospheric conditions.

Standard drying would require temperatures high enough to degrade the material just to evaporate the DMF.

By applying a vacuum, you significantly lower the boiling point of these solvents. This allows moisture and DMF trapped in the micropores and particle interstices to evaporate efficiently at just 60°C.

preventing Chemical Oxidation

The "amino" aspect of CoPc-NH2 refers to reduced amino functional groups, which are chemically sensitive.

Exposing these groups to air (oxygen) at high temperatures creates a high risk of oxidation.

The vacuum environment eliminates oxygen from the drying chamber. This ensures the amino groups remain in their reduced, active state, preserving the chemical identity of the catalyst.

Ensuring Physical Integrity

Maintaining Surface Activity

Catalytic performance is heavily dependent on surface area.

If the powder is dried in a standard oven, the surface tension of evaporating liquids can pull particles together, leading to agglomeration.

Vacuum drying mitigates these forces, resulting in a loose, non-agglomerated powder. This keeps the active sites accessible and ensures high surface activity for subsequent applications.

Deep Pore Cleaning

Solvents are not just on the surface; they are trapped deep within the micropores.

Atmospheric drying often results in "skinning," where the surface dries and traps solvents inside the core.

The pressure differential in a vacuum oven forces these deep-seated volatiles outward, ensuring the material is thoroughly dried from the inside out.

Understanding the Trade-offs

The Risk of Standard Ovens

Using a conventional air-circulation oven is a critical error for this material.

To remove DMF in air, you would need temperatures that would almost certainly char or oxidize the amino groups, rendering the catalyst useless.

Time vs. Temperature

While the vacuum allows for lower temperatures (60°C), it requires patience.

The primary protocol requires a 24-hour cycle. Rushing this process by increasing the heat—even under vacuum—risks thermal degradation of the organic framework.

Making the Right Choice for Your Goal

To ensure the highest quality CoPc-NH2 powder, strictly adhere to the vacuum protocol.

- If your primary focus is Chemical Purity: Ensure the vacuum is maintained for the full 24 hours to guarantee the complete removal of DMF from the micropores.

- If your primary focus is Catalytic Activity: strictly limit the temperature to 60°C to prevent any thermal stress on the amino functional groups.

By controlling the atmosphere and pressure, you turn a destructive drying process into a preservation step.

Summary Table:

| Feature | Vacuum Oven Drying (60°C) | Standard Atmospheric Oven |

|---|---|---|

| Boiling Point (DMF) | Significantly lowered; evaporates at 60°C | Requires high heat (>150°C) |

| Oxidation Risk | Minimal (Oxygen-free environment) | High (Heat + Air degrades amino groups) |

| Powder Integrity | Loose, high surface area; no agglomeration | Risk of 'skinning' and particle clumping |

| Drying Depth | Deep-pore cleaning via pressure differential | Surface drying only; traps internal solvents |

Maximize Your Catalyst Performance with KINTEK Precision

Preserving the delicate amino functional groups of CoPc-NH2 requires precise thermal control and reliable vacuum integrity. KINTEK provides industry-leading vacuum systems designed to handle sensitive chemical synthesis and deep-pore solvent removal.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique laboratory requirements. Whether you are drying advanced catalysts or scaling up high-temp synthesis, our equipment ensures consistent results without compromising material integrity.

Ready to upgrade your lab's drying capabilities? Contact KINTEK today to find the perfect thermal solution for your research!

Visual Guide

References

- Xue Lü, Andrea Fratalocchi. Hydrogen‐Bond‐Assisted Synthesis of Single‐Atom and Nanocluster Synergistic Sites for Enhanced Oxygen Reduction Reaction. DOI: 10.1002/adfm.202506982

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is vacuum annealing and what benefits does it provide? Achieve Superior Material Properties and Pristine Surfaces

- Why is precise heating slope control in a vacuum heat treatment furnace critical for niobium oxide experiments?

- Why is a high-temperature homogenization furnace treatment necessary for (CoCrNi)94Al3Ti3 alloys? Ensure Metal Purity

- How does the vacuum environment contribute to medical device manufacturing? Ensure Purity and Precision for Patient Safety

- Why is a vacuum furnace used for high-temperature annealing of Ti–TEG composites at 700 K?

- What vacuum level is required for AlCrSiWN coating deposition? Achieving Peak Purity and Adhesion

- What is the role of a vacuum drying oven in N-TiO2@NC preparation? Preserve MXene Integrity and Chemical Stability