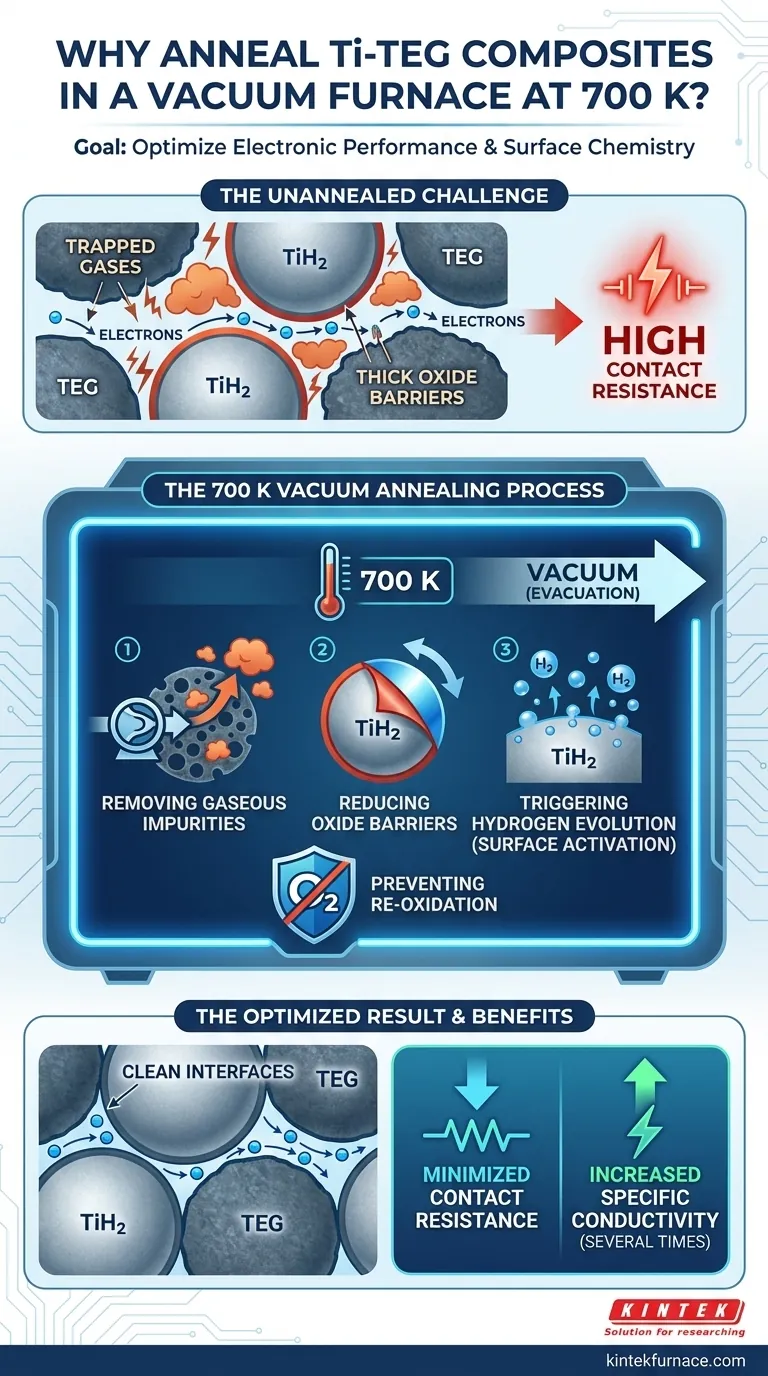

A vacuum furnace is utilized for high-temperature annealing of Titanium Hydride–Thermally Expanded Graphite (Ti–TEG) composites at 700 K to fundamentally alter the material's surface chemistry and optimize its electronic performance. This specific environment is required to remove impurities and facilitate chemical reactions that are impossible to achieve in an oxygen-rich atmosphere.

Core Takeaway The vacuum environment serves as a critical purification stage, stripping away insulating gaseous impurities and reducing oxide layers that block electrical flow. By cleaning the interface between particles, this process significantly lowers contact resistance and increases the composite's specific electrical conductivity by several times.

The Mechanisms of Optimization

Removing Gaseous Impurities

Thermally Expanded Graphite (TEG) is porous and prone to trapping gases. The vacuum environment effectively evacuates these residual gaseous impurities from the TEG structure.

Eliminating these gases is essential because they act as contaminants that inhibit the interaction between the graphite and the titanium components.

Reducing Oxide Barriers

Titanium is highly reactive and forms oxide layers that are electrically insulating. The 700 K vacuum anneal facilitates the partial reduction of these oxide layers.

By thinning or removing this oxide "skin," the process exposes the conductive material underneath, allowing for better electrical contact between the composite's components.

Triggering Hydrogen Evolution

The heating process within the vacuum triggers hydrogen evolution reactions on the surfaces of the Titanium Hydride (TiH2) particles.

This reaction chemically activates the surface of the particles, further preparing them for closer physical and electrical integration with the graphite matrix.

Impact on Electrical Properties

Minimizing Contact Resistance

The primary goal of the annealing process is to lower contact resistance.

Unannealed composites suffer from high internal resistance due to the presence of surface oxides and trapped gases at the interfaces between particles.

Increasing Specific Conductivity

Once the impurities are removed and the surfaces are activated, electrons can flow more freely through the material.

The primary reference notes that this specific treatment causes the specific electrical conductivity of the composite to increase several times compared to its unannealed state.

Understanding the Necessity of Vacuum

Preventing Oxidation

While the primary goal is to reduce existing oxides, the vacuum also prevents new oxides from forming.

Titanium elements oxidize extremely easily at high temperatures. Without a high vacuum to isolate oxygen, heating the material to 700 K would thicken the oxide layer rather than reduce it, destroying the material's conductivity.

Ensuring Material Density

Though the primary focus is electronic properties, the vacuum environment also assists in exhausting residual gases between layers.

If these gases were not removed, they could form pore defects within the composite, which would interrupt the conductive pathways and mechanically weaken the structure.

Making the Right Choice for Your Goal

## Optimizing Ti–TEG Composite Preparation

- If your primary focus is maximizing electrical conductivity: You must prioritize the vacuum annealing step at 700 K to strip insulating oxides and lower contact resistance.

- If your primary focus is process efficiency: Ensure your vacuum system is capable of effectively evacuating evolved hydrogen and desorbed gases to prevent re-contamination during the heating cycle.

High-performance conductive composites rely less on the raw materials used and more on the purity of the interfaces between them.

Summary Table:

| Mechanism | Impact on Ti–TEG Composite | Objective |

|---|---|---|

| Gaseous Impurity Removal | Evacuates gases from porous TEG structure | Eliminates insulating contaminants |

| Oxide Layer Reduction | Strips insulating oxide 'skin' from titanium | Lowers contact resistance between particles |

| Hydrogen Evolution | Chemically activates TiH2 particle surfaces | Facilitates integration with graphite matrix |

| Vacuum Isolation | Prevents oxidation at high temperatures | Maintains material purity and conductivity |

Elevate Your Advanced Material Synthesis with KINTEK

Precise control over vacuum and temperature is non-negotiable for critical processes like the annealing of Ti–TEG composites. KINTEK provides industry-leading vacuum solutions designed to eliminate oxidation, manage hydrogen evolution, and maximize the electrical performance of your materials.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your lab's unique high-temperature needs.

Ready to optimize your composite research? Contact us today to find your perfect furnace solution!

Visual Guide

References

- M. Yakymchuk, E. G. Len. Structure and Electronic Properties of Composite Hydrogenated Titanium–Thermally Expanded Graphite Before and After Vacuum Furnace Annealing. DOI: 10.15407/mfint.45.09.1041

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Which industries benefit from vacuum furnaces? Unlock Material Perfection for Aerospace, Medical, and More

- Why use low-speed heating (600-700°C) in Al-Ti-Zr sintering? Mastering Aluminum Phase Transition for Success.

- Why do the crucible residues remaining after the vacuum distillation of magnesium alloys possess high recycling value?

- What is vacuum annealing and what benefits does it provide? Achieve Superior Material Properties and Pristine Surfaces

- Why is a high vacuum level required for a thermal evaporator? Ensure Pure Transition Metal Oxide (TMO) Deposition

- What is the primary function of industrial vacuum plasma nitriding equipment? Boost Tool Steel Performance & Durability

- How does a sintering furnace work? Master the Process for Superior Material Properties