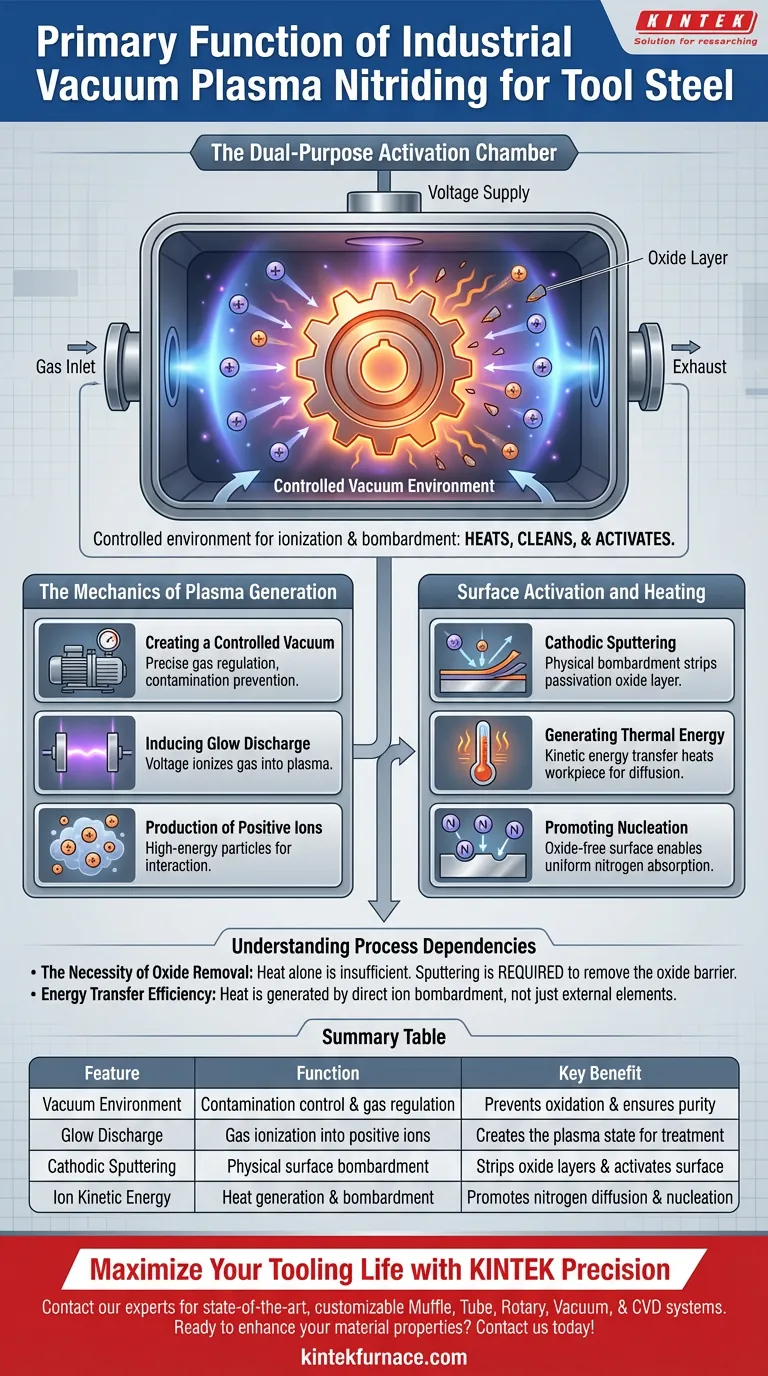

The primary function of industrial vacuum plasma nitriding equipment is to create a controlled environment that facilitates the ionization of gas and the subsequent bombardment of the workpiece. By applying voltage to induce a glow discharge, the equipment generates high-energy positive ions that physically strike the tool steel, simultaneously heating it and cleaning its surface to prepare it for nitrogen absorption.

The equipment acts as a dual-purpose activation chamber: it uses cathodic sputtering to strip away stubborn oxide layers while generating the thermal energy necessary for nitrogen to diffuse deep into the steel.

The Mechanics of Plasma Generation

Creating a Controlled Vacuum

The equipment first establishes a controlled vacuum environment. This is the fundamental prerequisite for the process, ensuring that the gas composition can be precisely regulated and preventing contamination from atmospheric gases.

Inducing Glow Discharge

Once the vacuum is established, the equipment applies voltage to the system. This electrical potential induces a glow discharge, a phenomenon where the gas within the chamber is ionized.

Production of Positive Ions

The ionization process converts the gas into positive ions. These are electrically charged, high-energy particles that are crucial for the physical interaction with the tool steel surface.

Surface Activation and Heating

Cathodic Sputtering

The positive ions are accelerated toward the workpiece, bombarding the surface with significant force. This bombardment produces a "sputtering" effect, effectively removing the passivation oxide layer.

Removing Barriers to Diffusion

Tool steel often has an oxide layer that inhibits chemical treatment. By physically stripping this layer via sputtering, the equipment exposes the fresh metal underneath, making it chemically active.

Generating Thermal Energy

The impact of these high-energy particles does more than just clean; it transfers kinetic energy into heat. This generates the thermal energy required to drive the diffusion of nitrogen into the steel matrix.

Promoting Nucleation

The combination of a clean, oxide-free surface and sufficient thermal energy promotes the adsorption and nucleation of nitrogen atoms. This ensures the nitriding layer forms uniformly and adheres strongly to the substrate.

Understanding Process Dependencies

The Necessity of Oxide Removal

A common misconception is that heat alone is sufficient for nitriding. However, without the cathodic sputtering provided by this equipment, the surface passivation layer on tool steel would act as a barrier, preventing nitrogen penetration regardless of the temperature.

Energy Transfer Efficiency

The process relies on the direct bombardment of the surface to generate heat. This means the efficiency of the thermal energy generation is directly tied to the intensity and control of the ion bombardment, rather than external heating elements alone.

Making the Right Choice for Your Goal

To maximize the effectiveness of vacuum plasma nitriding, consider how the equipment's functions align with your specific metallurgical requirements.

- If your primary focus is Surface Cleanliness: Ensure the equipment is calibrated to deliver sufficient sputtering energy to fully remove the passivation oxide layer before diffusion begins.

- If your primary focus is Diffusion Efficiency: Monitor the voltage and glow discharge stability to maintain the consistent thermal energy required for deep nitrogen penetration.

The ultimate value of this equipment lies in its ability to turn the tool steel surface into a highly active receptor for nitrogen through precise ionic bombardment.

Summary Table:

| Feature | Function in Plasma Nitriding | Key Benefit for Tool Steel |

|---|---|---|

| Vacuum Environment | Contamination control & gas regulation | Prevents oxidation & ensures purity |

| Glow Discharge | Gas ionization into positive ions | Creates the plasma state for treatment |

| Cathodic Sputtering | Physical surface bombardment | Strips oxide layers & activates surface |

| Ion Kinetic Energy | Heat generation & bombardment | Promotes nitrogen diffusion & nucleation |

Maximize Your Tooling Life with KINTEK Precision

Don't let passive oxide layers compromise your heat treatment. At KINTEK, we provide state-of-the-art industrial vacuum solutions designed to deliver superior surface activation and uniform nitrogen diffusion. Backed by expert R&D and world-class manufacturing, our systems—including Muffle, Tube, Rotary, Vacuum, and CVD systems—are fully customizable to meet the rigorous demands of your metallurgical processes.

Ready to enhance your material properties? Contact our technical experts today to find the perfect high-temperature furnace for your unique needs!

Visual Guide

References

- Magdalena Mokrzycka, Maciej Pytel. The influence of plasma nitriding process conditions on the microstructure of coatings obtained on the substrate of selected tool steels. DOI: 10.7862/rm.2024.1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What function does a High-Pressure Hydrogen Annealing Furnace serve? Achieving Deep Saturation in Steel Samples

- What benefits does vacuum provide in a vacuum brazing furnace? Achieve Stronger, Cleaner Joints with Precision

- How do multi-point temperature sensors monitor vacuum furnace uniformity? Ensure ±3°C Precision in Heat Treatment

- Why is a vacuum arc-melting furnace preferred for Co-Ti-V quaternary superalloys? Ensure Purity & High-Temp Precision

- What types of metals and alloys are suitable for vacuum heat treatment furnaces? Essential Guide for High-Performance Materials

- What is the primary purpose of using a vacuum drying oven for rGO/tMO composites? Ensure Purity and Structural Integrity

- Why are vacuum furnaces considered important in various industries? Unlock Superior Material Performance

- Why is a vacuum drying oven used for TiB2 ceramic slurry? Protect Material Purity & Performance