Vacuum drying is the superior method for processing TiB2 ceramic slurry because it utilizes negative pressure to lower the boiling point of solvents, such as anhydrous ethanol, allowing for rapid evaporation at significantly lower temperatures. Unlike standard blast drying ovens that rely on hot air circulation, a vacuum oven creates an oxygen-deficient environment that directly inhibits the surface oxidation of highly active TiB2 micropowders.

By decoupling temperature from evaporation, vacuum drying preserves the chemical purity of reactive powders and prevents the formation of hard agglomerates. This ensures the material retains the high surface activity and uniform particle distribution required for high-density sintering.

Preserving Chemical Integrity

Inhibition of Oxidation

Titanium Diboride (TiB2) micropowders are chemically active and prone to oxidation when exposed to heated air. Standard blast ovens circulate hot oxygen-rich air, which accelerates surface oxidation. Vacuum drying eliminates oxygen from the chamber, neutralizing this risk and preserving the original chemical properties of the powder.

Thermal Protection via Reduced Boiling Points

In a standard oven, solvents must reach high temperatures to evaporate effectively. A vacuum environment lowers the system pressure, which drops the boiling point of organic solvents like ethanol. This allows for rapid desolvation at low temperatures, preventing thermal degradation or excessive grain growth in the ceramic particles.

Optimizing Physical Microstructure

Prevention of Hard Agglomeration

Drying in a blast oven often leads to "hard" agglomeration caused by liquid bridge forces and high heat. Vacuum drying mitigates these forces, preventing the powder from fusing into tight clusters. This results in a loose, friable powder that is easier to mold and sinter.

Eliminating Segregation

Standard blast ovens rely on thermal convection (air movement) to transfer heat, which can cause lighter and heavier particles within a slurry to separate or segregate. Vacuum drying occurs in a static environment without strong air currents. This maintains the compositional uniformity of the mixture, ensuring that additives and the main matrix remain homogeneously distributed.

Enhancing Sintering Performance

Removal of Trapped Gases

Vacuum drying creates a pressure differential that actively pulls trapped air bubbles and adsorbed moisture out of the powder clusters. If left inside, these volatiles would expand during the high-temperature sintering phase. Removing them early prevents the formation of pores, cracks, and structural defects in the final ceramic part.

Reaction Consistency

Because the powder remains unoxidized and chemically stable during drying, the subsequent sintering reactions occur predictably. This facilitates better densification, ensuring the final ceramic component achieves its theoretical density and mechanical strength.

Understanding the Trade-offs

While vacuum drying is technically superior for high-performance ceramics like TiB2, it introduces distinct operational challenges compared to blast ovens.

Heat Transfer Efficiency

Vacuum environments lack air, which is the primary medium for heat transfer in standard ovens. Consequently, heating active loads can be slower initially until the solvent begins to vaporize. This often requires conductive heating via shelf contact rather than convective heating, necessitating precise equipment calibration.

Equipment Complexity and Throughput

Vacuum ovens generally operate as batch processes and require vacuum pumps, seals, and pressure controllers. This makes the equipment more expensive to operate and maintain than simple blast drying ovens. However, for sensitive materials like TiB2, the cost is justified by the prevention of scrap caused by oxidation or cracking.

Making the Right Choice for Your Goal

When processing sensitive ceramic slurries, the choice of drying method dictates the ceiling of your material's performance.

- If your primary focus is Material Performance: Choose vacuum drying to guarantee chemical purity, prevent oxidation, and ensure high-density sintering.

- If your primary focus is Cost/Speed for Non-Critical Parts: A blast oven may suffice for inert materials, but it is not recommended for TiB2 due to the high risk of oxidation and defect formation.

For TiB2 ceramics, the vacuum drying oven is not just a drying tool; it is a critical process control step that safeguards the material's potential.

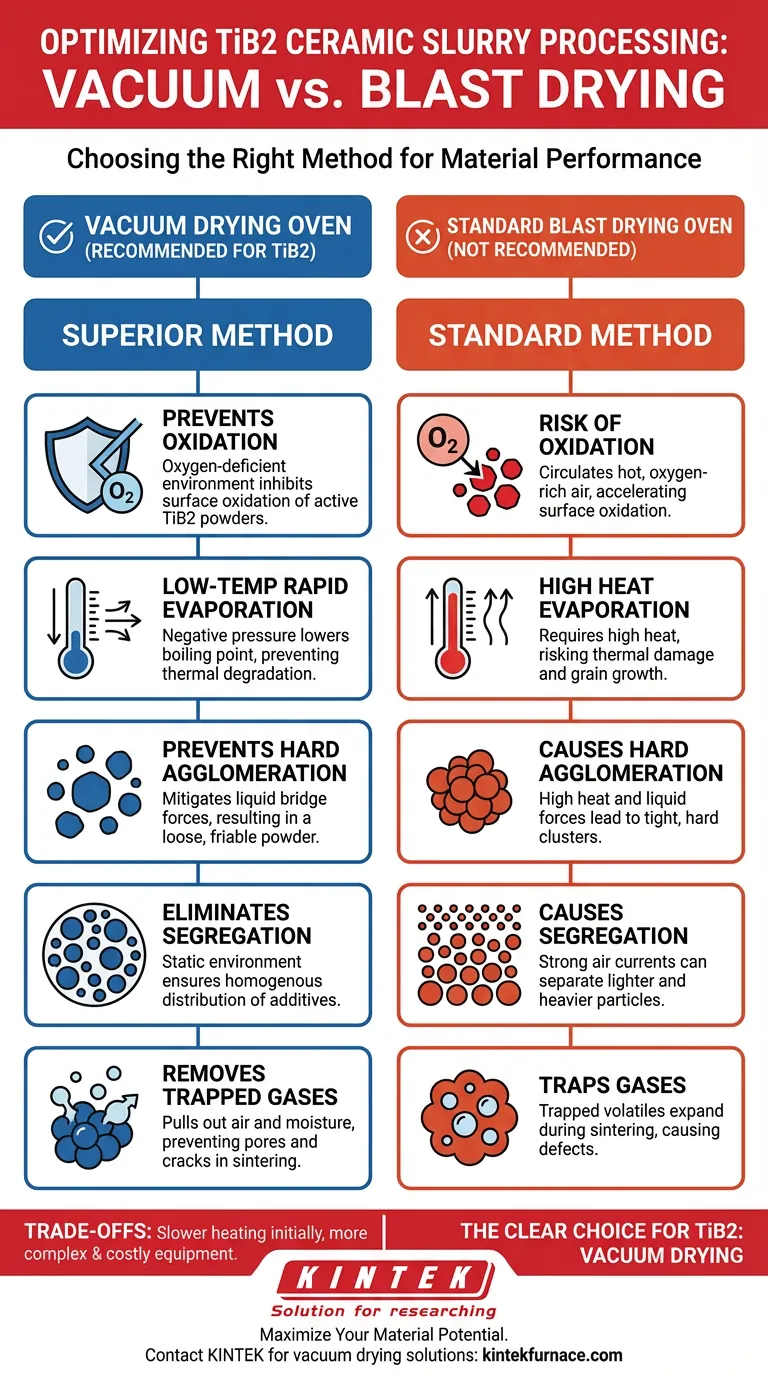

Summary Table:

| Feature | Vacuum Drying Oven | Standard Blast Drying Oven |

|---|---|---|

| Atmosphere | Oxygen-deficient (Prevents Oxidation) | Oxygen-rich (Risk of Oxidation) |

| Boiling Point | Lowered via negative pressure | Atmospheric (Requires higher heat) |

| Particle Quality | Loose, friable powder; no segregation | Risk of hard agglomerates & segregation |

| Final Sintering | High density, fewer defects | Potential for pores and cracks |

| Heat Transfer | Conductive/Radiant | Convective (Air circulation) |

Maximize Your Material Potential with KINTEK

Don't let oxidation or agglomeration compromise your TiB2 ceramic performance. KINTEK provides industry-leading vacuum drying solutions designed for the most sensitive lab and industrial applications. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique processing needs.

Ready to elevate your material processing?

Contact our technical experts today to discover how KINTEK’s precision high-temp furnaces can ensure your chemical purity and sintering consistency.

Visual Guide

References

- Sha Zhang, Shuge Tian. Spectral characterization of the impact of modifiers and different prepare temperatures on snow lotus medicinal residue-biochar and dissolved organic matter. DOI: 10.1038/s41598-024-57553-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is vacuum brazing particularly useful in aerospace and other high-precision industries? Achieve Superior, Contamination-Free Joints

- What is the significance of vacuum in relation to graphite components in furnaces? Prevent Oxidation for Extreme Temperatures

- Why is dual monitoring used for Tantalum annealing? Achieve 20K Precision in Vacuum Furnaces

- What is the significance of precise temperature control in a vacuum furnace? Ensure Quality, Consistency, and Reliability

- Why is removing oxygen important in a vacuum furnace? Prevent Oxidation for Superior Metal Quality

- What is the burnout cycle on a vacuum furnace? A Key to High-Purity Heat Treating

- Why is a high-temperature vacuum annealing furnace critical for alpha-Al2O3/MLG membranes? Master Ion Selectivity

- What are the common uses of graphite in vacuum furnaces? Essential for High-Temp Performance