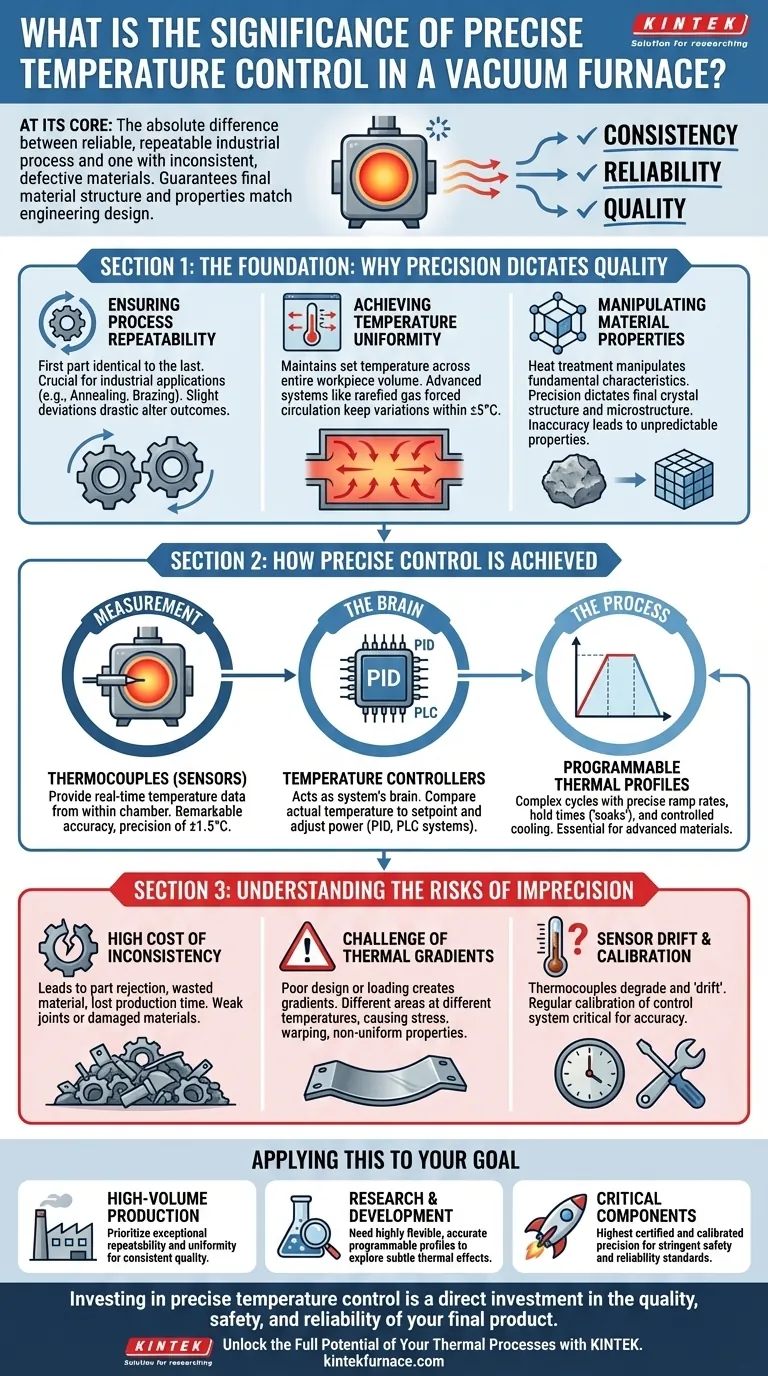

At its core, the significance of precise temperature control in a vacuum furnace is the absolute difference between a reliable, repeatable industrial process and one that produces inconsistent and defective materials. This precision ensures every part is treated exactly as intended, achieving the specific material properties required for its application, from annealing and brazing to advanced sintering.

A vacuum furnace is a tool for controlled material transformation. Precise temperature control is not merely a feature; it is the mechanism that guarantees the final material's structure and properties match the engineering design, ensuring consistency, reliability, and quality.

The Foundation: Why Precision Dictates Quality

The primary goal of any thermal process is to induce a specific, desirable change in a material. Temperature is the dominant variable in that equation.

Ensuring Process Repeatability

For any industrial application, the first part in a batch must be identical to the last. Precise temperature control is the only way to ensure this repeatability.

Whether you are softening a metal through annealing or joining components via brazing, slight deviations in temperature can drastically alter the outcome, leading to inconsistent product quality.

Achieving Temperature Uniformity

A single temperature reading is not enough. Temperature uniformity refers to maintaining the set temperature across the entire volume of the workpiece.

Advanced furnaces use systems like rarefied gas forced circulation to minimize temperature differences, often keeping variations within a tight band of ±5°C, ensuring the entire part receives the same treatment.

Manipulating Material Properties

Heat treatment is used to manipulate a material’s fundamental characteristics. Precision is paramount.

The final crystal structure, composition, and microstructure of a material are a direct result of the thermal cycle it endures. Inaccurate temperature control leads to unpredictable and undesirable final properties.

How Precise Control is Achieved

Modern vacuum furnaces operate as a sophisticated, closed-loop system. They continuously measure, evaluate, and adjust to maintain the desired thermal environment.

The Measurement: Thermocouples

Thermocouples are the sensory organs of the furnace, providing real-time temperature data from within the chamber.

These sensors can be remarkably accurate, allowing the system to monitor the furnace temperature with a precision of ±1.5°C, which is critical for sensitive processes.

The Brain: Temperature Controllers

The data from thermocouples is fed to a temperature controller, which acts as the system's brain.

Controllers range from PID (Proportional-Integral-Derivative) units to fully automated PLC (Programmable Logic Controller) or computer-based systems. They compare the actual temperature to the setpoint and adjust power to the heating elements accordingly.

The Process: Programmable Thermal Profiles

Modern control systems allow for complex, programmable heating cycles.

Users can define precise ramp-up rates, specific hold times (or "soaks") at target temperatures, and controlled cooling periods. This level of control is essential for creating advanced materials and components.

Understanding the Risks of Imprecision

A failure to maintain precise temperature control is not a minor issue; it is a direct cause of process failure and financial loss.

The High Cost of Inconsistency

Without precise control, achieving consistent results is impossible. This leads directly to part rejection, wasted material, and lost production time. A brazing process that is too cool may create a weak joint, while one that is too hot can damage the parent materials.

The Challenge of Thermal Gradients

Even with a precise controller, poor furnace design or improper part loading can create thermal gradients, where different areas of a part are at significantly different temperatures. This can induce stress, warping, or non-uniform material properties.

Sensor Drift and Calibration

Precision is not permanent. Thermocouples can degrade and "drift" over time, providing inaccurate readings. Regular calibration of the entire control system is a critical maintenance task to ensure the displayed temperature is the true temperature.

Applying This to Your Goal

Your specific process requirements will determine the level of precision you need.

- If your primary focus is high-volume production: Prioritize a system that guarantees exceptional repeatability and uniformity to minimize batch-to-batch variation and ensure consistent quality control.

- If your primary focus is research and development: You need a system with highly flexible and accurate programmable profiles to explore the effects of subtle thermal changes on new materials.

- If your primary focus is processing critical components (e.g., aerospace, medical): There is no substitute for the highest level of certified and calibrated precision to meet stringent safety standards and ensure absolute reliability.

Ultimately, investing in precise temperature control is a direct investment in the quality, safety, and reliability of your final product.

Summary Table:

| Aspect | Key Points |

|---|---|

| Process Repeatability | Ensures identical results in every batch, critical for industrial consistency. |

| Temperature Uniformity | Maintains tight temperature variations (±5°C) across workpieces for even treatment. |

| Material Property Control | Directly influences crystal structure and microstructure for desired outcomes. |

| Control Systems | Uses thermocouples (±1.5°C accuracy), PID/PLC controllers, and programmable profiles. |

| Risks of Imprecision | Leads to defects, part rejection, thermal gradients, and financial losses. |

Unlock the Full Potential of Your Thermal Processes with KINTEK

Precise temperature control is essential for achieving consistent, high-quality results in your laboratory or production line. At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements.

Whether you're focused on high-volume production, R&D, or processing critical components, our furnaces ensure reliability and efficiency. Don't let imprecision hold you back—contact us today to discuss how we can enhance your processes and deliver superior outcomes!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance