In short, removing oxygen from a vacuum furnace is critical to prevent oxidation. This chemical reaction degrades the quality, strength, and finish of metal parts when they are exposed to high temperatures, creating brittle, contaminant-filled components. A vacuum environment eliminates this threat, ensuring the integrity of the final product.

A vacuum furnace isn't just about heat; it's about control. By removing reactive gases like oxygen, you create a chemically pure environment where heat treatment can modify a material's properties without causing destructive side effects like oxidation.

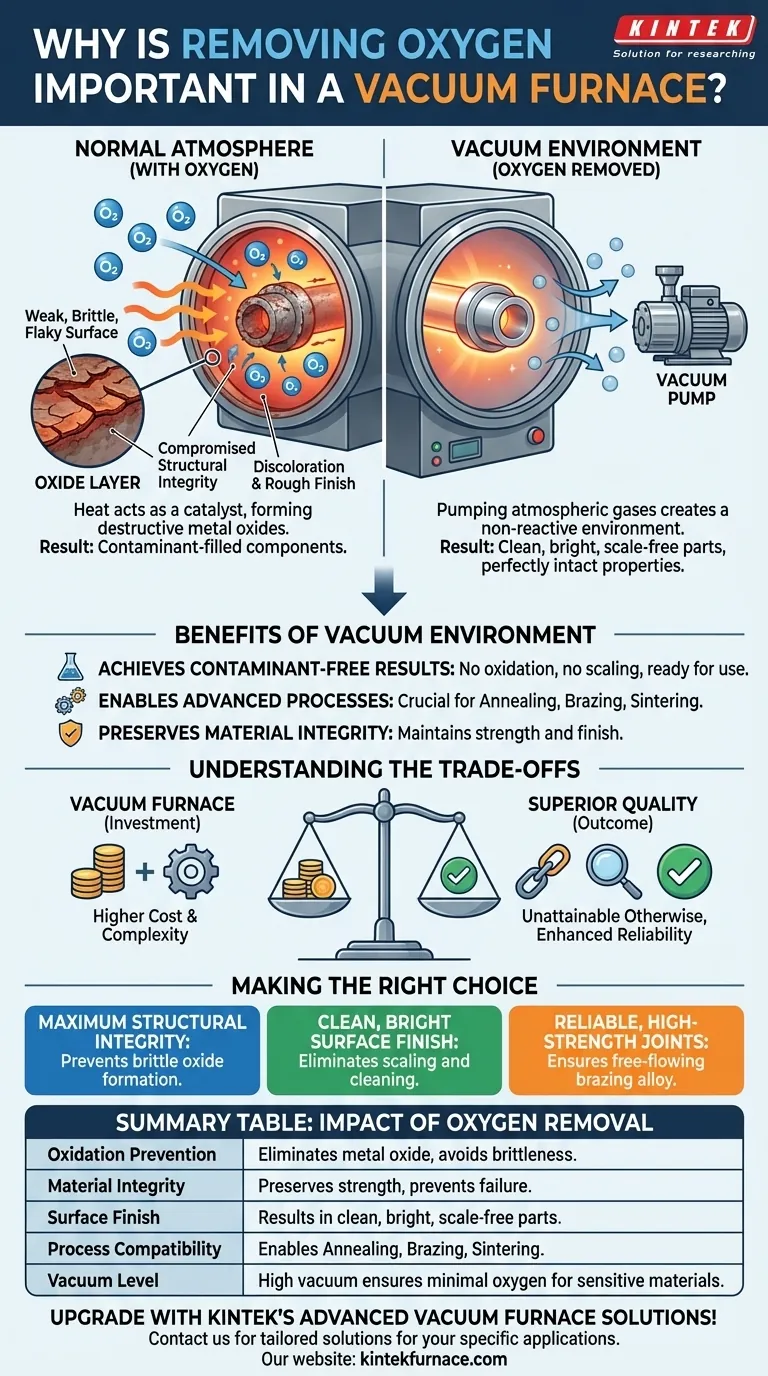

The Destructive Role of Oxygen in Heat Treatment

To understand the importance of a vacuum, we must first recognize why a normal atmosphere is the enemy of high-quality heat treatment. The air around us is a reactive mixture that becomes aggressive at high temperatures.

Understanding Oxidation at High Temperatures

Heat acts as a catalyst for oxidation, a chemical reaction where metal atoms lose electrons to oxygen atoms.

This process forms a new compound, a metal oxide, on the surface of the part. This oxide layer is fundamentally different from the parent metal.

The Impact on Material Integrity

Oxidation is not a harmless cosmetic issue. The resulting oxide layer is often brittle, flaky, and weak.

This compromises the structural integrity of the component, creating a failure point. It also leads to discoloration and a rough surface finish, requiring costly and difficult secondary cleaning operations.

Why a "Normal" Atmosphere Is Unsuitable

Ambient air composição is roughly 21% oxygen. Subjecting a metal part to high heat in this environment guarantees rapid and aggressive oxidation, undermining the very purpose of a controlled process like heat treatment.

The Benefits of a Vacuum Environment

By pumping atmospheric gases out of the chamber, a vacuum furnace creates an ideal, non-reactive environment. This unlocks a level of quality and process capability that is impossible to achieve in an open-air furnace.

Achieving Contaminant-Free Results

A vacuum removes the primary reactant: oxygen. This ensures the material is affected only by the precisely controlled heating and cooling cycles.

The result is a clean, bright, and scale-free part that comes out fatores ready for use, with its metallurgical properties perfectly intact.

Enabling Advanced Processes

Many critical heat treatment techniques are only viable in a vacuum because they are extremely sensitive to contaminants.

- Annealing: This process softens metal and relieves internal stresses. Oxidation would create a hard, brittle surface, defeating the purpose.

- Brazing: This joins components using a filler metal. Oxides prevent the filler from properly wetting and flowing into the joint, resulting in a weak or failed bond.

- Sintering: This fuses metal powders into a solid mass. Oxides on powder particles inhibit a strong, direct metallurgical bond from forming, weakening the final part.

Understanding the Trade-offs

While a vacuum环境 is superior, it's important to understand the context and limitations. The decision proteção a vacuum furnace involves balancing cost, complexity, and the required final quality.

The Criticality of Vacuum Level

"Removing oxygen" is not an all-or-nothing event. The quality of the vacuum—measured in units like Torr or millibar—determines how much residual oxygen remains.

For highly sensitive materials like titanium or certain superalloys, a deep or high vacuum is required to prevent even trace amounts of oxidation. A poor or "soft" vacuum may not be sufficient.

The Cost vs. Quality Equation

Vacuum furnaces are more complex and expensive to build, operate, and maintain than atmospheric furnaces.

The trade-off is a clear investment. You accept higher operational costs to achieve superior material properties, cleanliness, and process reliability that are simply unattainable otherwise.

Making the Right Choice for Your Goal

Selecting the right thermal processing environment肿瘤 depends entirely on your end goal.

- If your primary focus is maximum structural integrity: A vacuum is essential to prevent the formation of brittle oxide layers that compromise the material's strength.

- If your primary focus is a clean, bright surface finish: Removing oxygen is the only way to prevent surface scaling and discoloration, eliminating the need for post-process cleaning.

- If your primary focus is reliable, high-strength joints via brazing: A vacuum environment is non-negotiable to ensure the brazing alloy can flow freely and create a strong, void-free bond.

Ultimately, controlling the furnace atmosphere is as fundamental to modern metallurgy as controlling the temperature itself.

Summary Table:

| Aspect | Impact of Oxygen Removal |

|---|---|

| Oxidation Prevention | Eliminates metal oxide formation, avoiding brittleness and contamination |

| Material Integrity | Preserves structural strength and prevents failure points in components |

| Surface Finish | Results in clean, bright, scale-free parts without discoloration |

| Process Compatibility | Enables advanced techniques like annealing, brazing, and sintering |

| Vacuum Level | High vacuum ensures minimal residual oxygen for sensitive materials |

Upgrade your lab's capabilities with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering contaminant-free results and enhanced process reliability. Don't let oxidation compromise your outcomes—contact us today to discuss how our tailored solutions can benefit your specific applications!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes