In short, vacuum brazing is the preferred joining method in high-precision industries because the vacuum environment eliminates atmospheric contaminants, resulting in exceptionally strong, clean, and dimensionally stable bonds. This process allows for the creation of complex assemblies from sensitive materials with a level of reliability that conventional welding or brazing cannot achieve.

The core advantage is not just the heat, but the absence of air. By removing oxygen and other reactive gases, vacuum brazing creates a perfect metallurgical bond, free from the oxides and impurities that weaken joints and lead to failure in mission-critical applications.

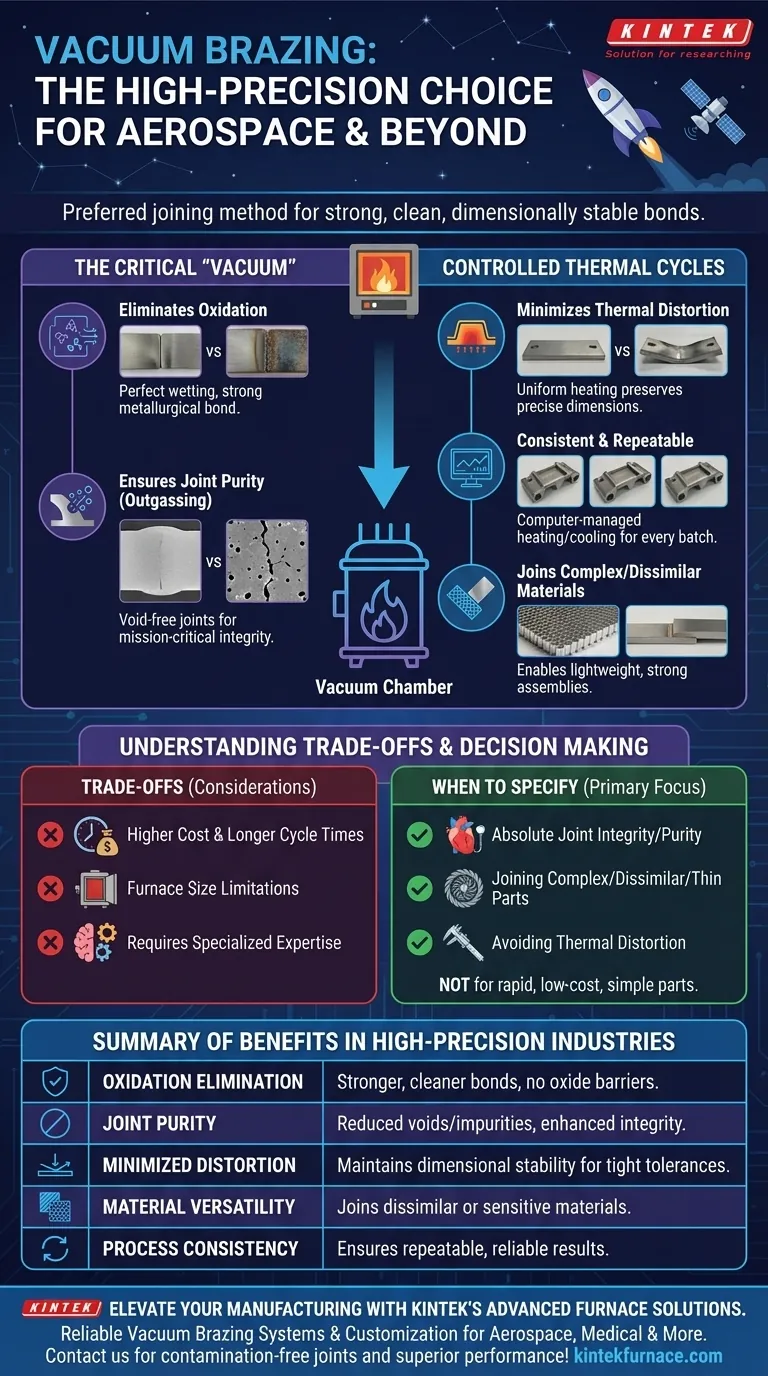

What Makes the 'Vacuum' in Vacuum Brazing Critical?

The defining feature of this process is the controlled atmosphere, or lack thereof. Removing air from the furnace chamber fundamentally changes how metals can be joined.

Eliminating Oxidation and Contamination

When metals are heated in the presence of air, their surfaces instantly form oxide layers. These layers act as a barrier, preventing the brazing filler metal from properly wetting and bonding with the parent materials, leading to weak or incomplete joints.

A vacuum removes virtually all oxygen, ensuring the metal surfaces remain perfectly clean. This allows the molten filler alloy to flow freely via capillary action, creating a seamless, powerful metallurgical bond across the entire joint interface.

Ensuring Unmatched Joint Purity

The vacuum environment also pulls trapped gases and other volatile impurities out of the parent metals themselves in a process called outgassing.

This results in an extremely pure, void-free joint with superior structural integrity. For medical implants or aerospace components, this purity is non-negotiable, as internal voids could become crack initiation sites under stress.

The Advantage of Controlled Thermal Cycles

Beyond the vacuum itself, the process relies on precise, computer-controlled heating and cooling within a furnace, which offers distinct advantages over localized heating methods like welding.

Minimizing Thermal Distortion

Welding introduces intense, localized heat, creating significant thermal gradients that cause materials to warp, twist, and build up internal stress. This is unacceptable for parts with tight tolerances.

Vacuum brazing heats the entire assembly slowly and uniformly. This lack of a sharp thermal gradient minimizes distortion and residual stress, preserving the precise dimensions of even the most complex components.

Consistent and Repeatable Results

The entire heating and cooling profile is managed by a computer. This ensures that every part in a batch, and every subsequent batch, is processed with identical parameters.

This level of control guarantees highly reproducible results, a critical requirement for aerospace and medical manufacturing where quality cannot vary.

Joining Complex and Dissimilar Materials

The gentle, uniform heating makes it possible to join materials that are difficult or impossible to weld. This includes joining very thin materials to thick sections or joining dissimilar metals with different thermal expansion rates.

This capability is essential for creating lightweight yet strong components, such as honeycomb panels or advanced heat exchangers used in aircraft.

Understanding the Trade-offs

While powerful, vacuum brazing is not the universal solution for all joining applications. It involves specific limitations and considerations.

Higher Cost and Longer Cycle Times

Vacuum furnaces represent a significant capital investment, and the process itself is inherently slow. The time required to pump down the vacuum, run the thermal cycle, and cool the parts makes it a batch process with a much lower throughput than automated welding.

Limitations on Part Size

The component being brazed must fit inside the furnace's vacuum chamber. While very large industrial furnaces exist, the process is ultimately constrained by chamber dimensions.

Requires Specialized Expertise

Successful vacuum brazing is a highly technical discipline. It requires deep knowledge of metallurgy, chemistry, vacuum technology, and thermal engineering to develop and execute a successful process.

When to Specify Vacuum Brazing

The decision to use vacuum brazing should be driven by the specific requirements of the component.

- If your primary focus is absolute joint integrity and purity: Vacuum brazing is essential for medical implants, surgical tools, and critical aerospace sensors where any contamination could lead to catastrophic failure.

- If your primary focus is joining complex, thin, or dissimilar materials without distortion: The controlled thermal cycle is superior to all other methods for maintaining tight tolerances on intricate assemblies like heat exchangers or turbine components.

- If your primary focus is rapid, low-cost joining of simple, non-critical parts: Conventional welding, soldering, or torch brazing will likely be a more economical and faster solution.

For applications where failure is not an option, vacuum brazing provides a level of quality and reliability that other joining methods simply cannot match.

Summary Table:

| Key Aspect | Benefit in High-Precision Industries |

|---|---|

| Oxidation Elimination | Prevents oxide layers for stronger, cleaner bonds |

| Joint Purity | Reduces voids and impurities for enhanced integrity |

| Minimized Distortion | Maintains dimensional stability in complex parts |

| Material Versatility | Enables joining of dissimilar or sensitive materials |

| Process Consistency | Ensures repeatable, reliable results for critical applications |

Elevate your manufacturing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable vacuum brazing systems, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Our deep customization capabilities ensure precise solutions for your unique experimental needs, delivering contamination-free joints and superior performance in aerospace, medical, and other high-precision industries. Contact us today to discuss how we can enhance your process and achieve unparalleled quality!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How is vacuum heat treatment applied to elastic alloys? Unlock Peak Performance in Aerospace and Medical Devices

- Why is precise temperature and time control in a vacuum brazing furnace necessary for joint performance? Get Expert Tips

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- How do the radiant heating and controlled cooling functions of a vacuum brazing furnace benefit Kovar-to-SS joints?

- How does a vacuum brazing furnace enhance 17-4PH aging? Precision Microstructure & Superior Surface Integrity